Processing method for artemia sporocyst

A technology of cysts and magnetic particles, applied in the field of Artemia nauplii, can solve the problems of heavy labor and the influence of the viability of cysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

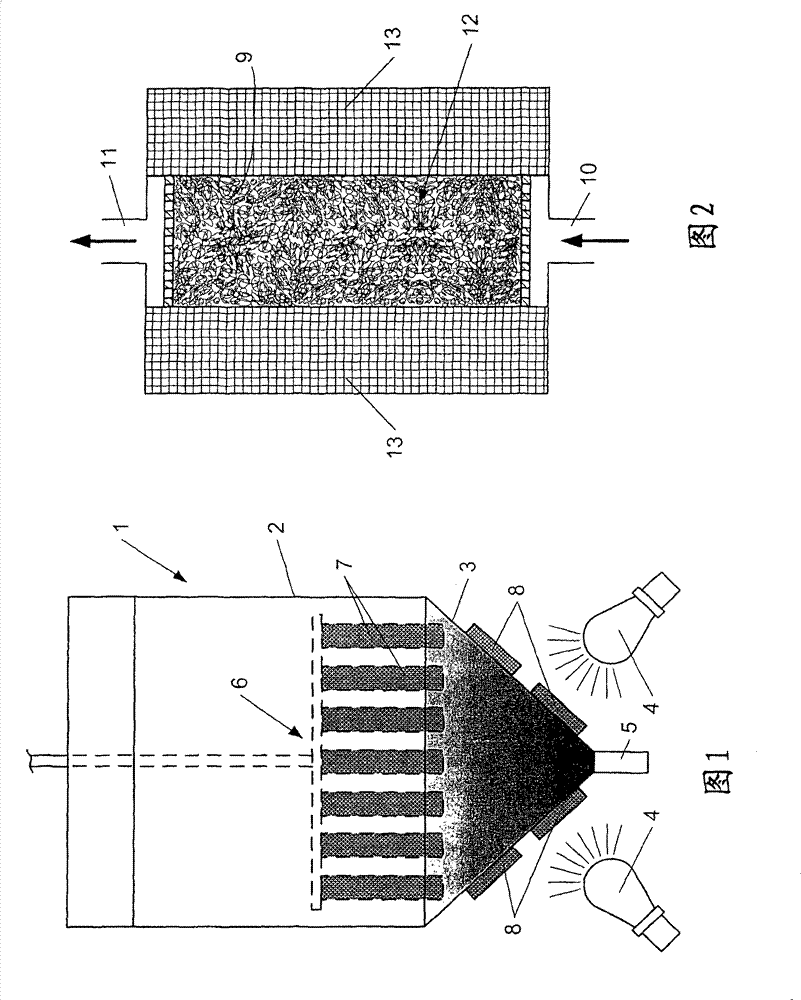

Method used

Image

Examples

Embodiment

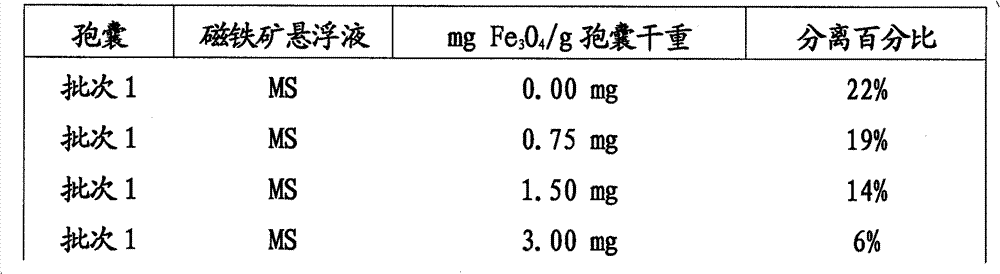

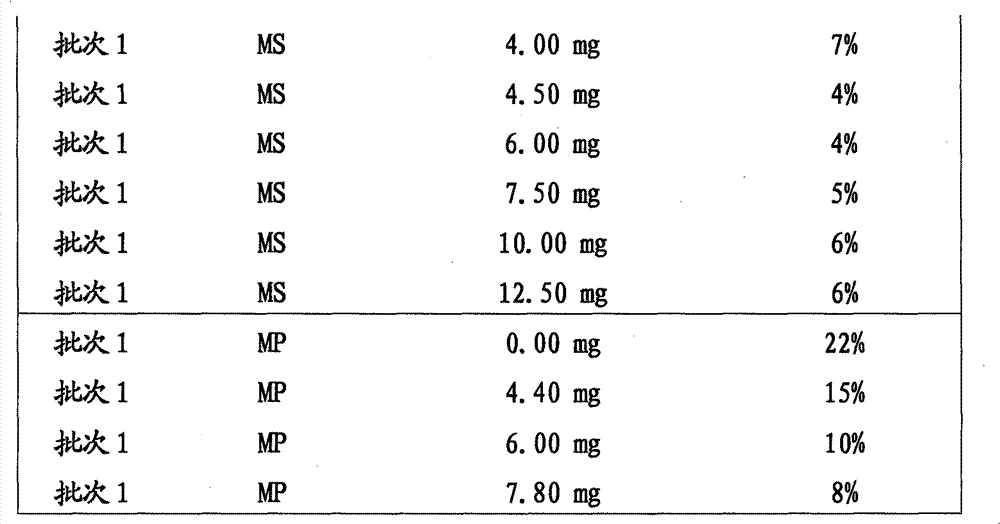

[0041] All reagents and chemicals used in these experiments were of analytical grade and were from Sigma Aldrich (Belgium). Magnetite suspension (MS) was obtained by mixing ferrous chloride tetrahydrate (FeCl 2 .4H 2 O), ferric chloride hexahydrate (FeCl 3 .6H 2 O), sodium hydroxide (NaOH) and water with stirring. The mixture forms a suspension of Fe 3 o 4 nanoparticles. The preparation thus prepared contained about 0.1 g of Fe 3 o 4 / ml.

[0042] Magnetite powder (iron(II,III) oxide, Sigma Aldrich, powder <5 μm) (MP) was suspended in water before coating onto cysts.

[0043] To coat magnetic particles with the method of the invention, 5 ml aliquots of different coating materials (MS and MP) at different concentrations were mixed with 50 g of different cyst types (water content of cysts ± 10%). Positive coating results were evident from visual inspection of the cysts.

[0044] One liter cones were used in which 2 g of Artemia cysts were incubated in artificial seawa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com