Connecting device of drain pipe

A connecting device and drainage pipe technology, which is applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of cracking, easy deformation of pipe, uneven connection strength of electric heating belt, etc., and reduce labor Strength, overcoming uneven connection strength, relatively low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

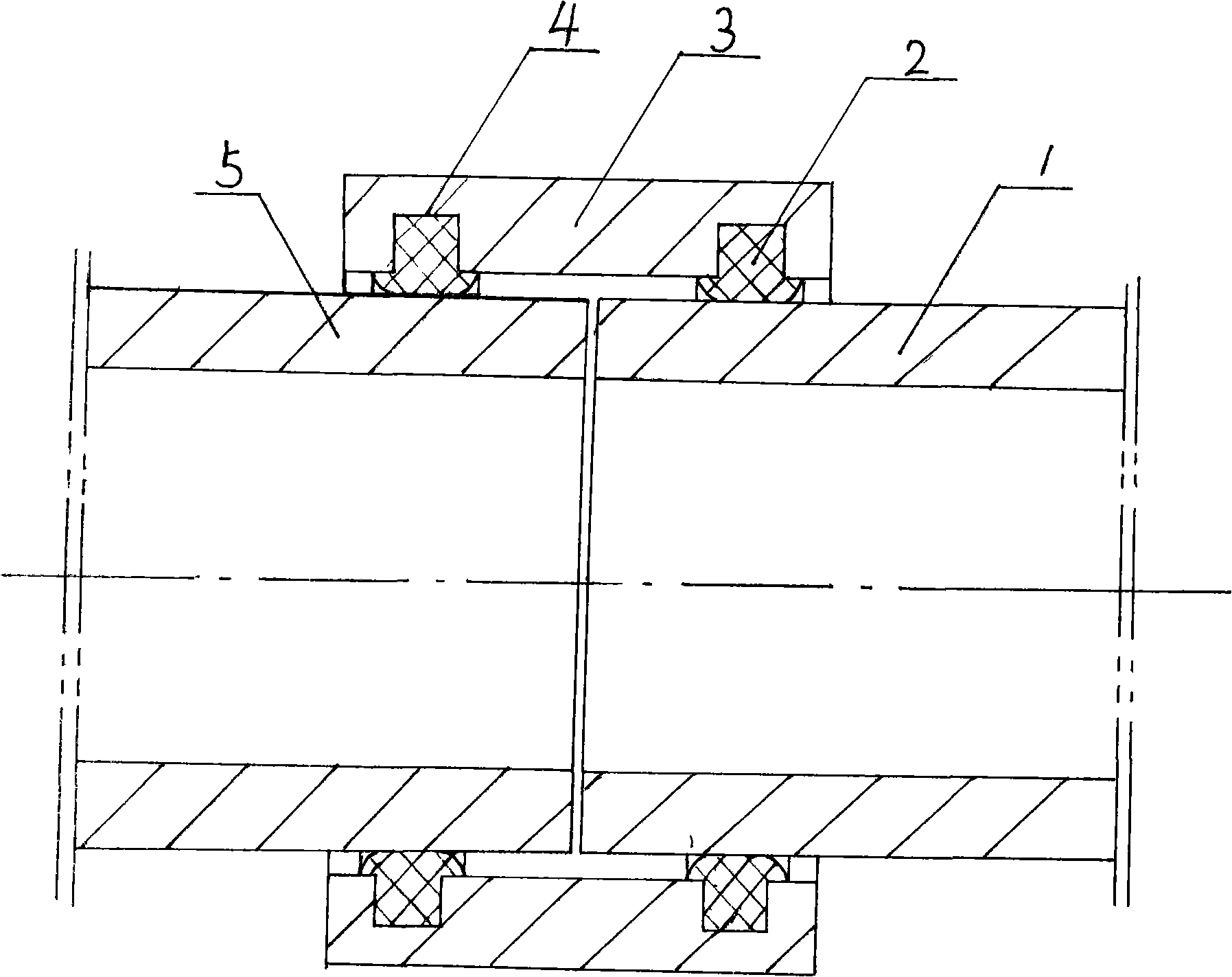

[0010] See attached figure 1 , the material of the connecting pipe (3) is a winding pipe, and the annular grooves (4) provided at both ends of the inner cavity of the connecting pipe (3) are respectively fixed with rubber sealing rings (2), and the winding pipes at both ends of the connecting pipe (3) ( 1), (5) are respectively inserted into the connecting pipe (3), and the winding pipes (1), (5) pass through and squeeze the sealing ring (2) in the annular groove (4) to achieve sealing.

Embodiment 2

[0012] See attached figure 1 , the material of the connecting pipe (3) is a straight wall pipe, and the annular grooves (4) provided at both ends of the inner cavity of the connecting pipe (3) are respectively fixed with rubber sealing rings (2), and the winding pipes at both ends of the connecting pipe (3) (1), (5) are respectively inserted into the connecting pipe (3), and the winding pipes (1), (5) pass through and squeeze the sealing ring (2) in the annular groove (4) to achieve sealing.

Embodiment 3

[0014] See attached figure 1 , the material of the connecting pipe (3) is cast iron pipe, the annular grooves (4) provided at both ends of the inner chamber of the connecting pipe (3) are respectively fixed with rubber sealing rings (2), and the winding pipes at both ends of the connecting pipe (3) ( 1), (5) are respectively inserted into the connecting pipe (3), and the winding pipes (1), (5) pass through and squeeze the sealing ring (2) in the annular groove (4) to achieve sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com