Filled-concentrate countercurrent electric demineralizer and method thereof

A countercurrent electric and electric desalination technology, applied in separation methods, ion exchange water/sewage treatment, dispersed particle separation, etc. The effect of scaling, reducing operating current and operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

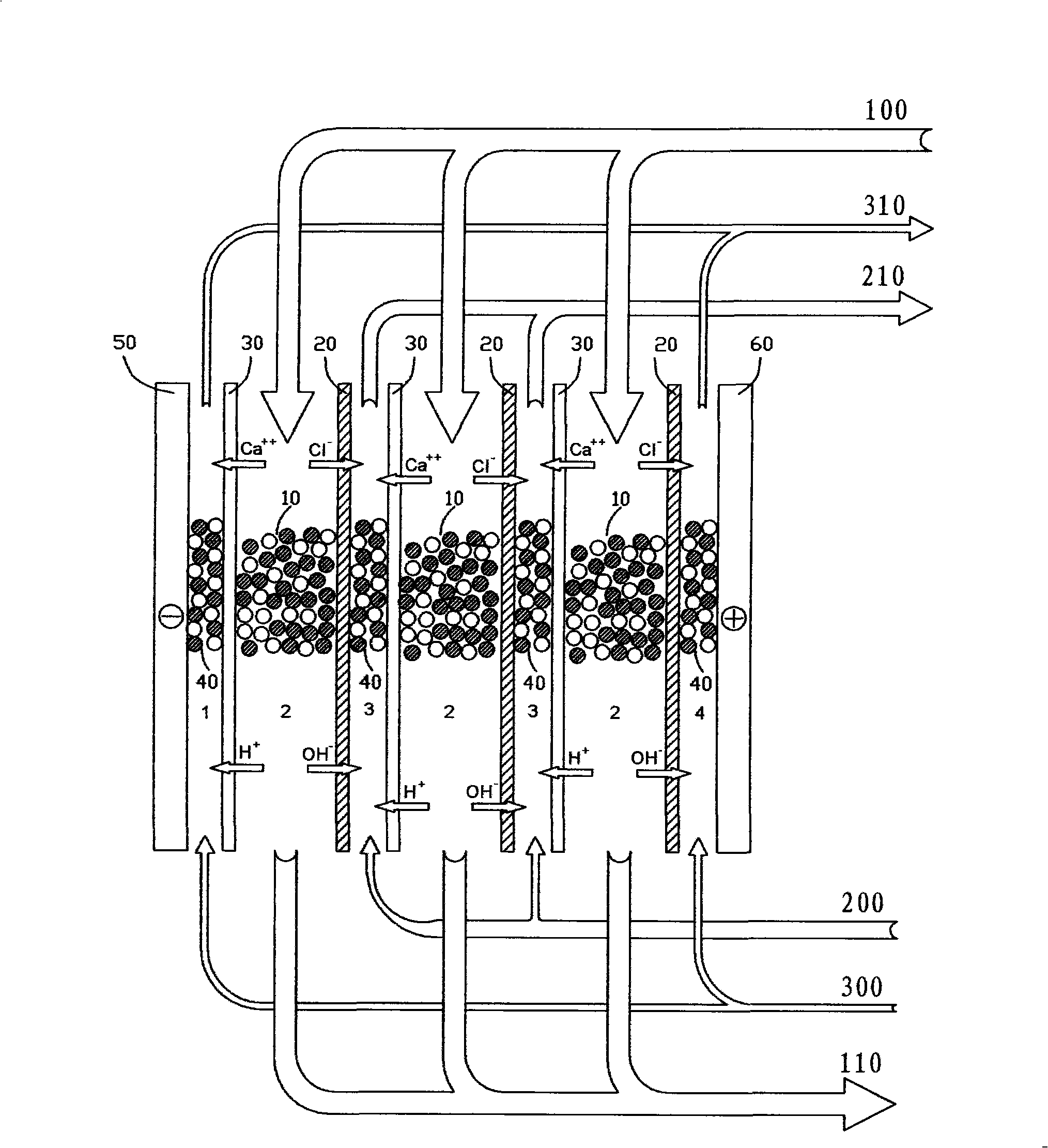

[0027] like figure 1 As shown, the electric desalination device is composed of forty pairs of anion exchange membranes and cation exchange membranes. The fresh water chamber 2, the concentrated water chamber 3 and the polar water chamber 1 are all filled with mixed ion exchange resins. The water and polar water enter and exit from the bottom, the conductivity of the feed water is 30uS / cm, the hardness is 10mg / L (calcium carbonate meter), the flow rate of fresh water is 3 cubic meters per hour, the flow rate of concentrated water is 0.3 cubic meters, and the flow rate of polar water is 0.06 cubic meters per hour. The operating parameters of the electrostatic desalination device are shown in Table 1 after the actual operation reaches a steady state.

[0028] Table 1 Test results of concentrated water filling countercurrent electric desalination device

[0029] Current (A) (±0.1)

[0030] After obtaining the above data, the countercurrent electric desalination device ...

Embodiment 2

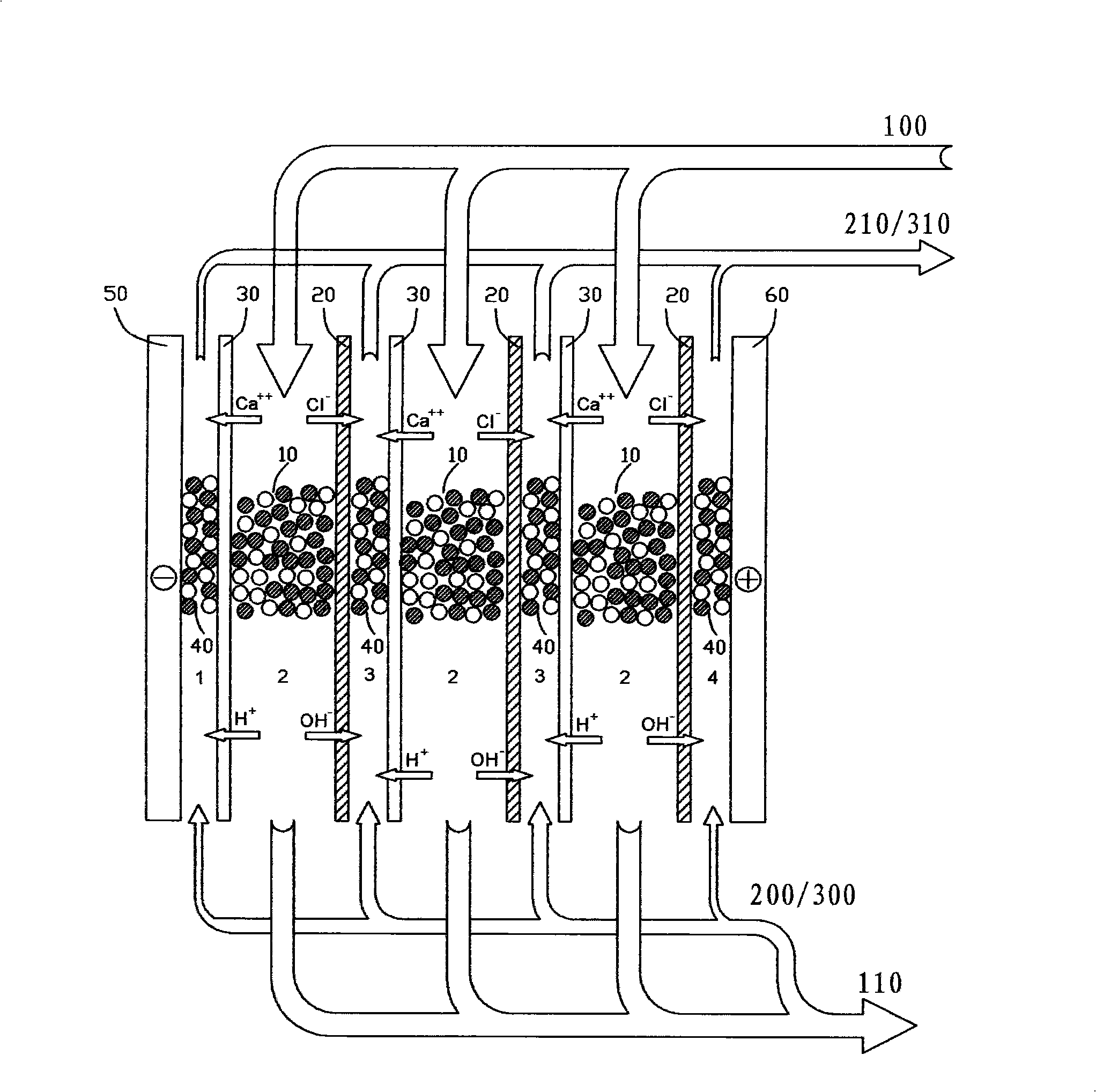

[0032] like figure 2 As shown, the internal structure of the device is the same as in Example 1, but the inflows 200 and 300 of the concentrated water and the polar water are combined, and the effluents 210 and 310 of the concentrated water and the polar water are combined, and the inflow of the concentrated water and the polar water is fresh water Feed water conductivity 45uS / cm, hardness 35mg / L (calcium carbonate), other conditions are the same as in Example 1, and the operation parameters of the electrostatic desalination device are shown in Table 2 after reaching a steady state.

[0033] Table 2 Test results of high hardness applicable parts of concentrated water filling countercurrent electric desalination device

[0034] Current (A) (±0.1)

[0035] After obtaining the above data, the countercurrent electric desalination device has been continuously operated at 4.0A for 2000 hours, and the resistivity, flow rate of fresh water, flow rate and pressure of concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com