Drum-type vacuum paper-absorbing device and working method thereof

A vacuum suction, roller type technology, used in printing, printing presses, general parts of printing machinery, etc., can solve the problems affecting detection quality, paper skew, paper affecting detection quality, etc., to achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

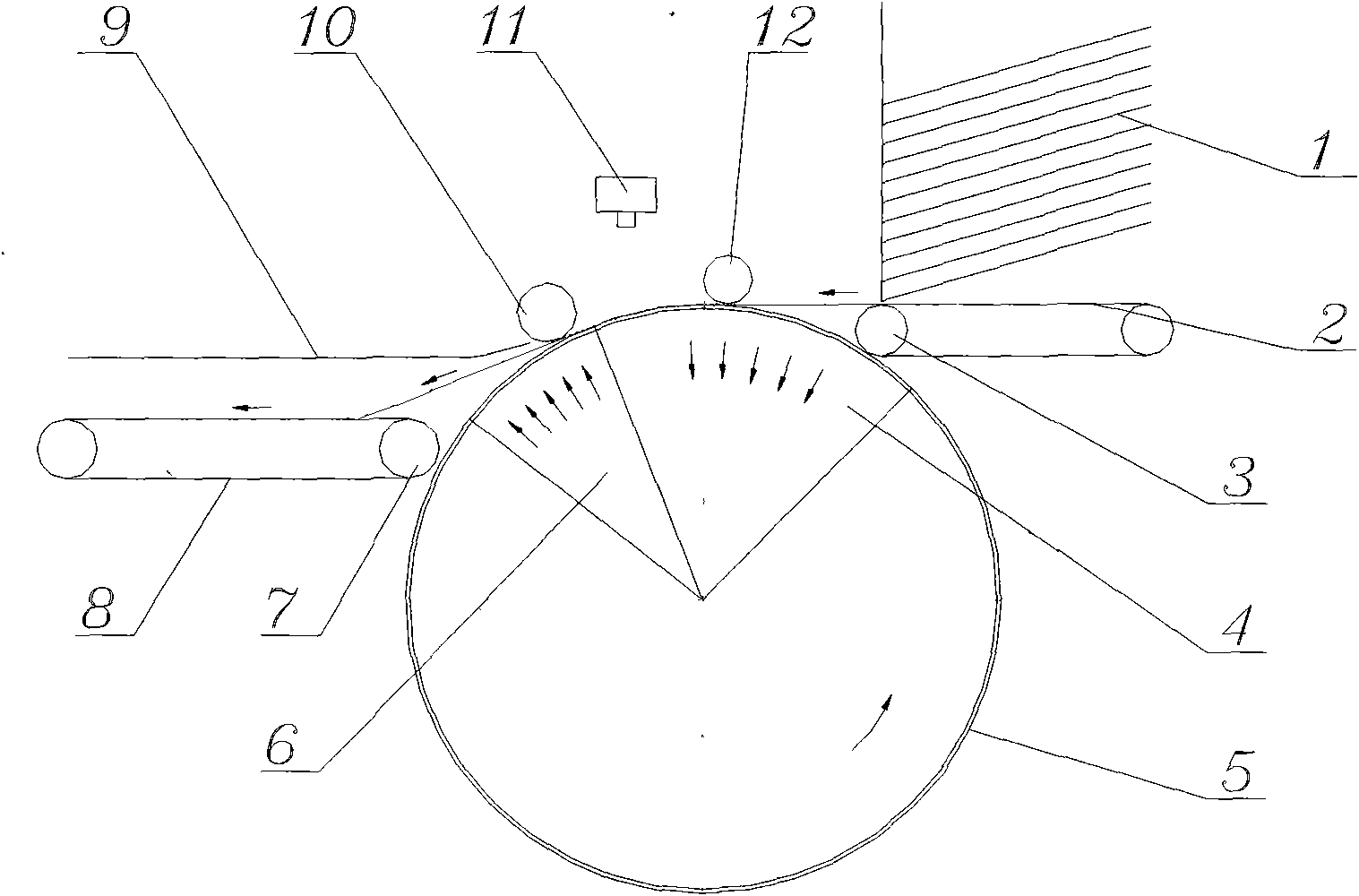

[0022] Embodiment: a drum-type vacuum suction device, characterized in that it is composed of a vacuum suction area 4, a large drum 5 and an air blowing area 6, wherein the surface of the large drum 5 is covered with small holes, and the inside of the large drum 5 is provided with a vacuum Suction area 4 and air blowing area 6; said vacuum suction area 4 placed inside the large drum 5 is located at the paper outlet of the large drum 5; said blowing area 6 placed inside the large drum 5 is located at the large drum 5 Roller 5 paper outlet.

[0023] The small holes that the above-mentioned big cylinder 5 surface is covered with are regularly arranged.

[0024] The above-mentioned vacuum suction area 4 located inside the large drum 5 is a space in the large drum 5, and the air in the space is continuously drawn out by a vacuum pump, and the surface of the large drum corresponding to the vacuum suction area 4 forms a vacuum to absorb the paper .

[0025] The above-mentioned blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com