Mold base device for pressing component with stepped mandrel

A technology of steps and mandrels, applied in presses, manufacturing tools, etc., can solve problems such as products that cannot be used to press mandrels with steps, and limited use scope, and achieve great practical and popularization value, reasonable structure, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

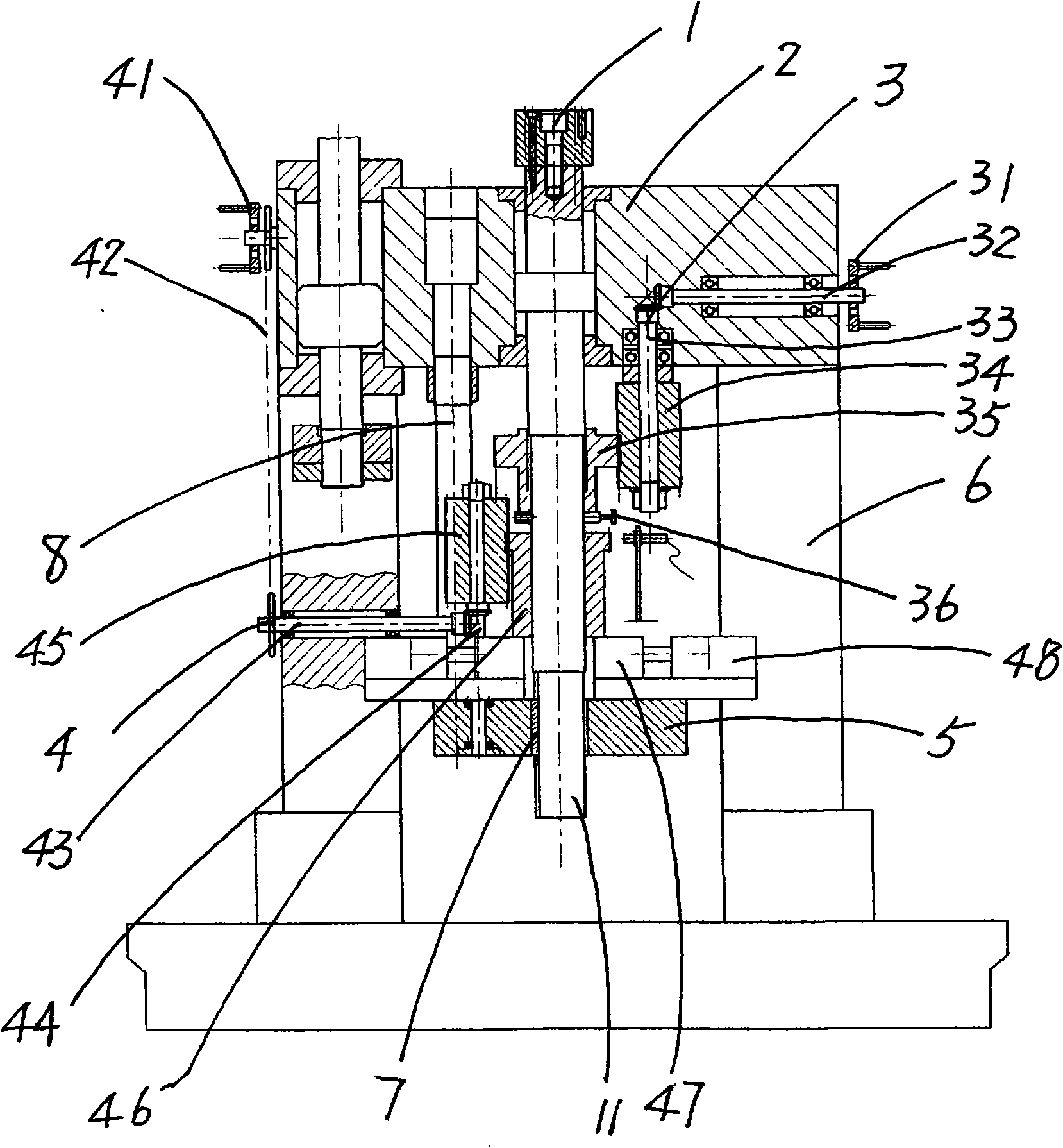

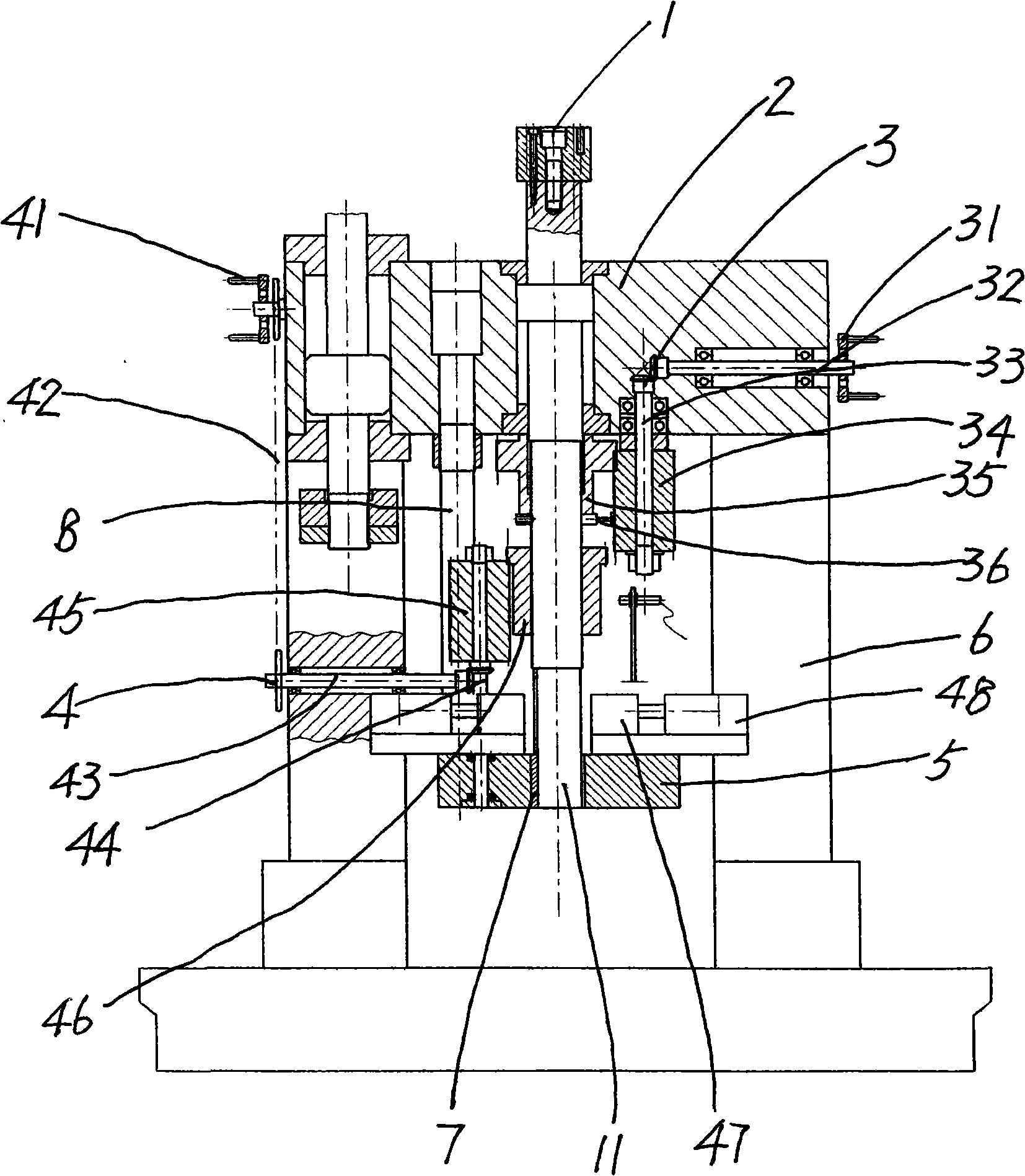

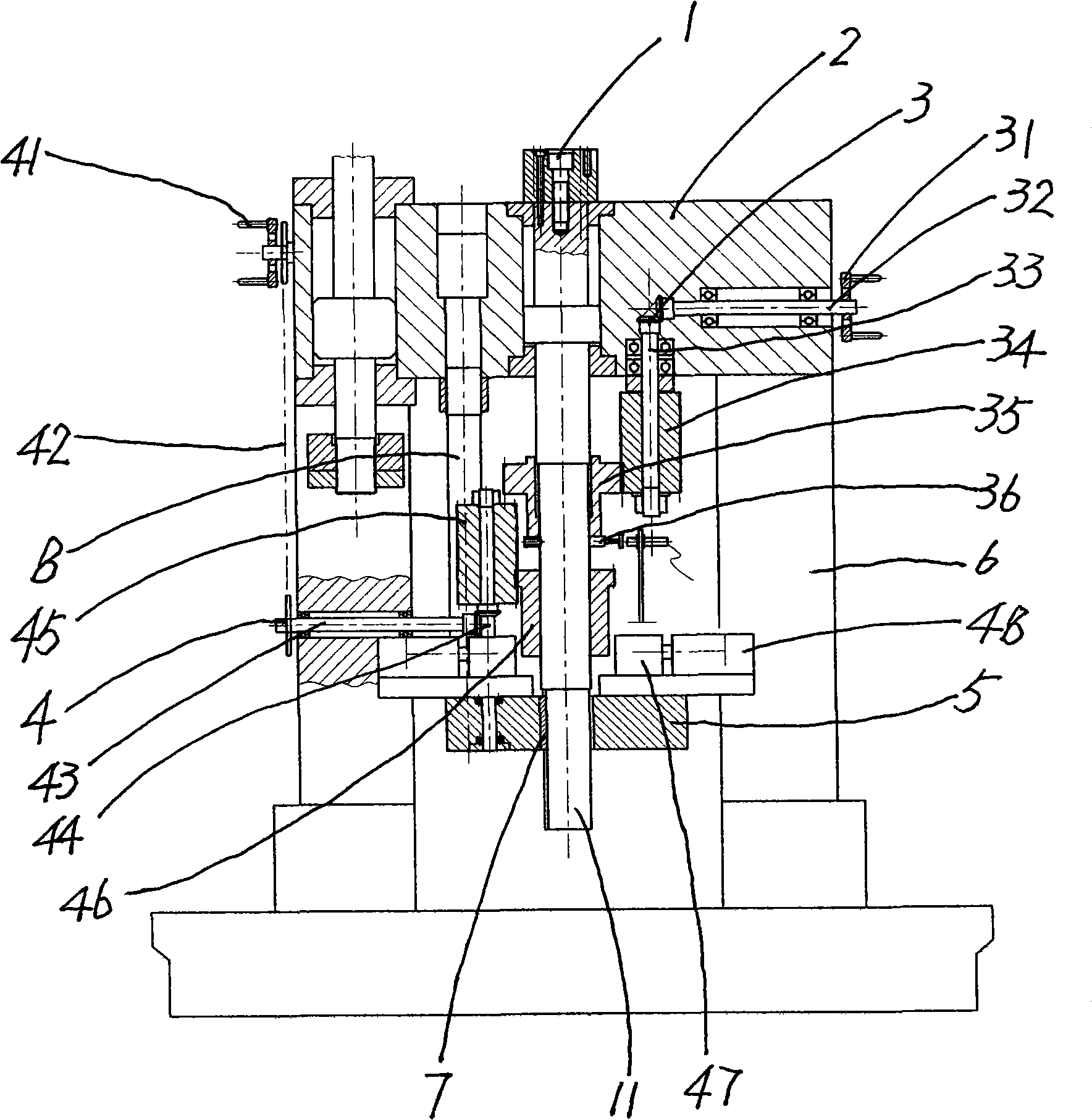

[0013] Refer to attached figure 1 , a formwork device for pressing mandrels with stepped parts according to the present invention includes a lower central cylinder 1, an upper fixed formwork 2, a height adjustment device for ejection and feeding 3, a mandrel step limiter 4, a lower fixed formwork 5, The supporting plate 6, the guide key 7, and the connecting rod 8 are in the working state of pressing and forming in this embodiment. The lower central cylinder 1 is arranged on the upper fixed formwork 2; the upper fixed formwork 2 is provided with the lower central cylinder 1 and is connected with the lower central cylinder 1, and is used for adjusting the ejection feeding height adjustment device 3 of the feeding height; the support plate 6 is connected with the upper The fixed formwork 2 is connected, and the support plate 6 is supported on the hydraulic press workbench; the lower fixed formwork 5 is connected with the upper fixed formwork 2 through the connecting rod 8; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com