Thread feeder

A technology of yarn feeder and yarn feeding wheel, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of function damage, function loss, unpleasantness, etc., and achieve the effect of improving visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

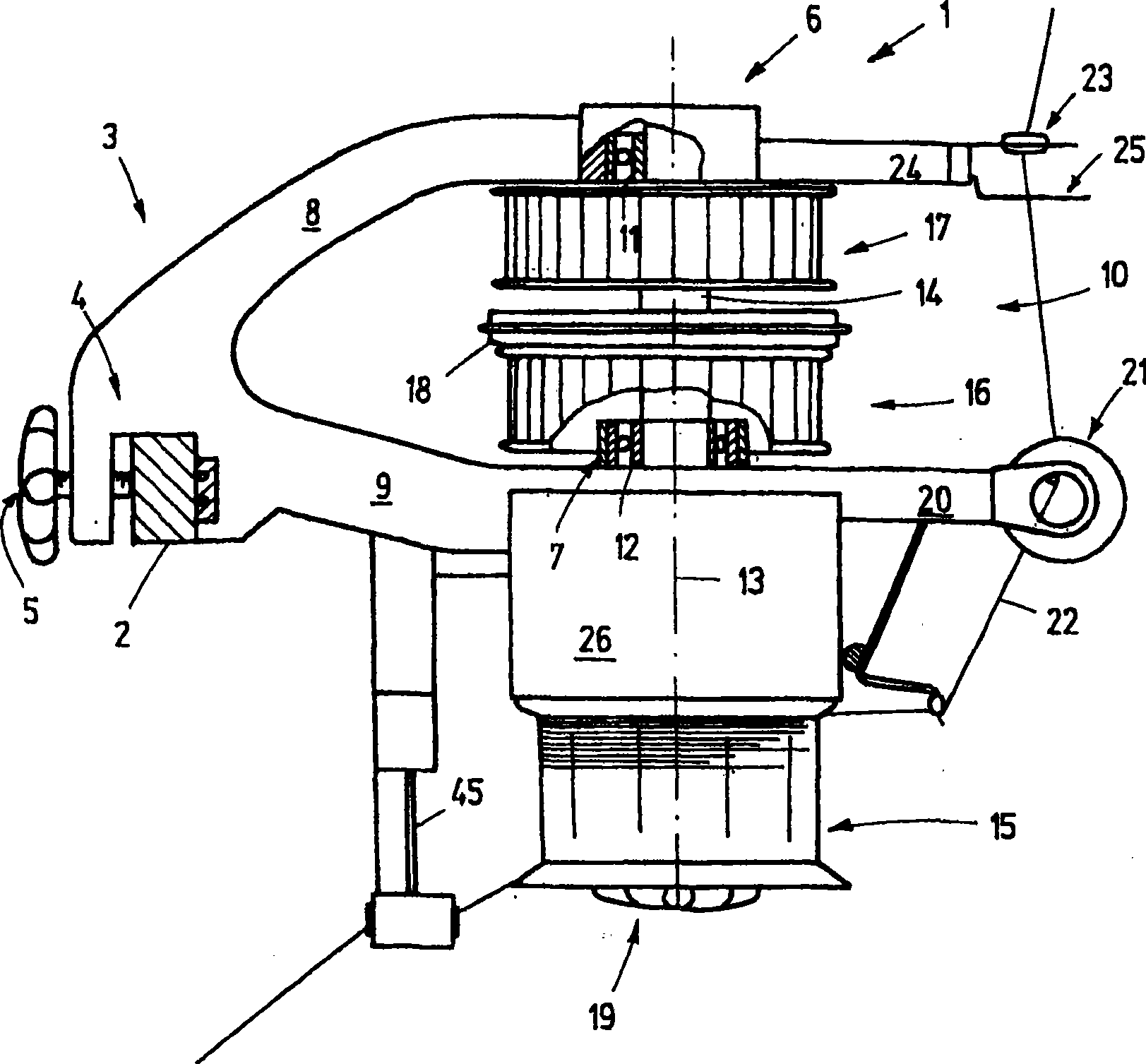

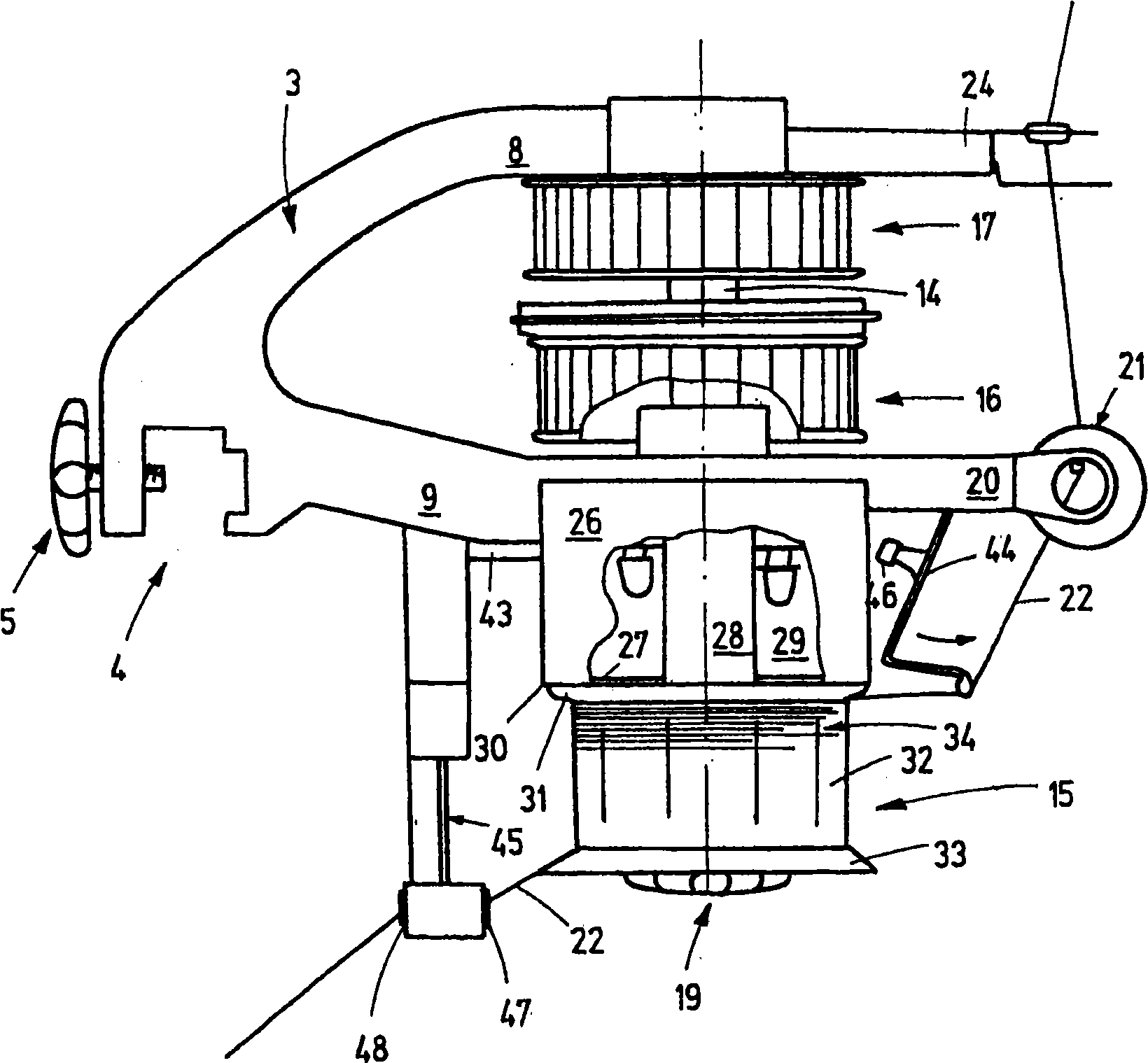

[0027] exist figure 1 Illustrated in is a yarn feeder 1 for feeding yarn to a knitting machine, for example a circular knitting machine. For this purpose, a large number of such yarn feeders are assembled on the hoop 2, which is arranged horizontally on the circular knitting machine. The yarn feeder 1 has a support 3 which has clamps 4 for fastening on the hoop 2 . The carrier 4 is, for example, a metal part, such as an aluminum die-cast part, a zinc die-cast part or a plastic injection-molded part or a plastic die-cast part. The clamp 4 has a downwardly open opening for receiving the hoop and a fastening screw 5 in order to clamp the hoop 4 in the opening. The bracket 3 extends from the clamp 4 to a first upper bearing arrangement 6 and a second lower bearing arrangement 7 . For this bracket can be as figure 1 Shown in has, for example, two rectilinear or arcuate arms 8 , 9 defining a gap 10 between them.

[0028] Such as figure 1 As shown, a bearing 11 , 12 in the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com