A structure of liquid crystal display panel

A technology for liquid crystal display panels and substrates, which can be used in static indicators, nonlinear optics, optics, etc., and can solve the problems of insufficient liquid crystal filling, reduced scrap cost, and uneven chromaticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

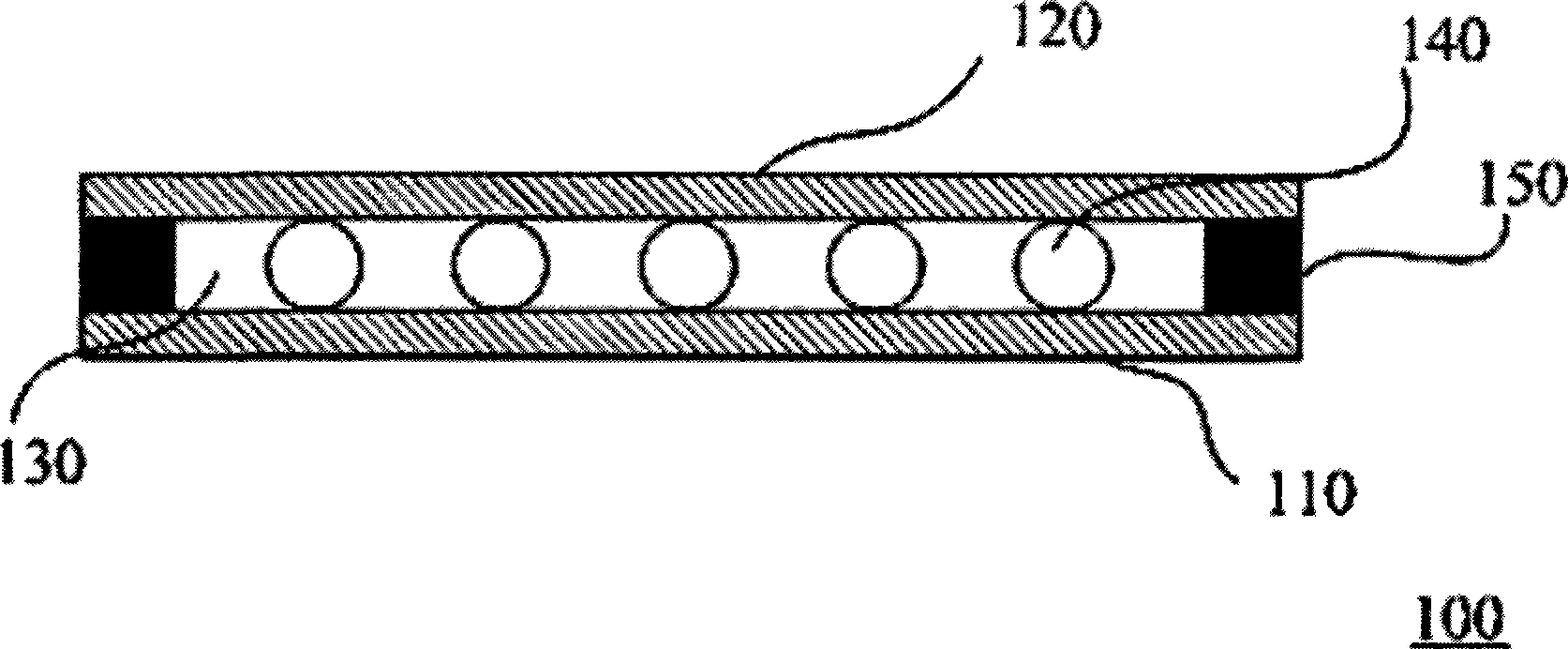

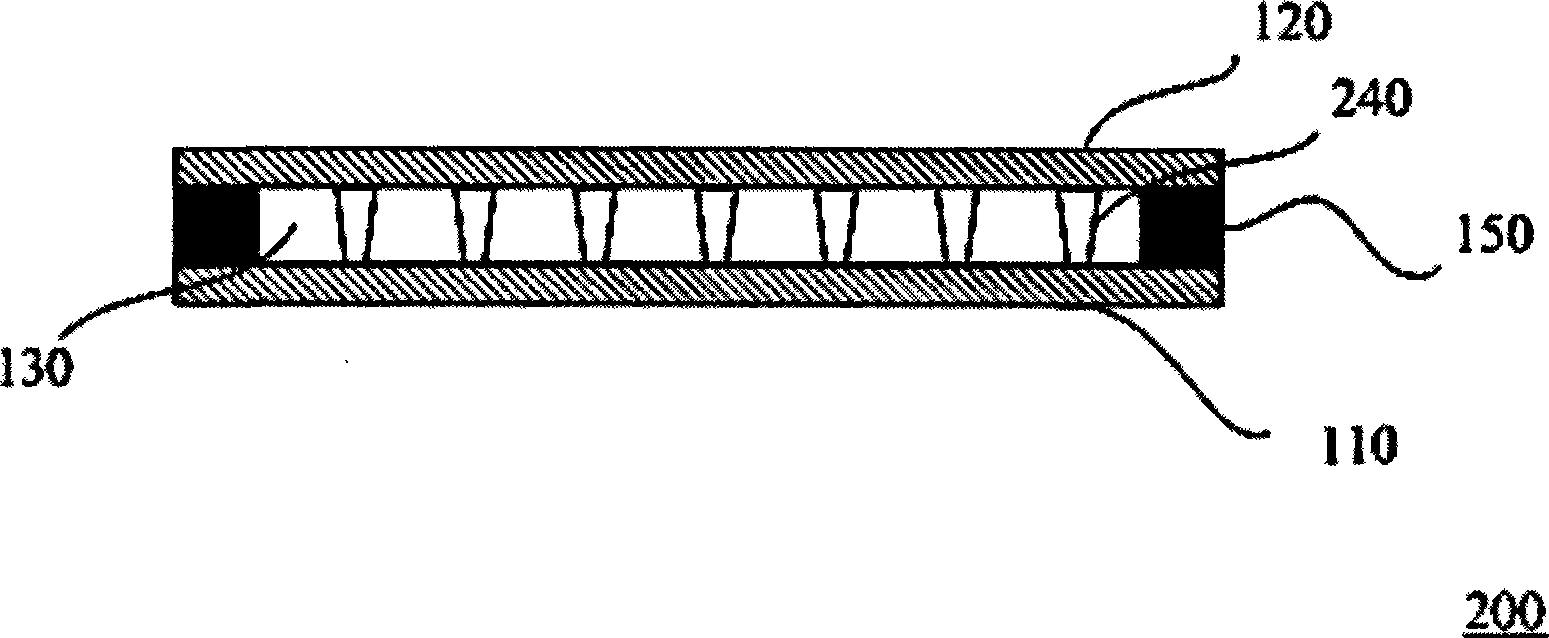

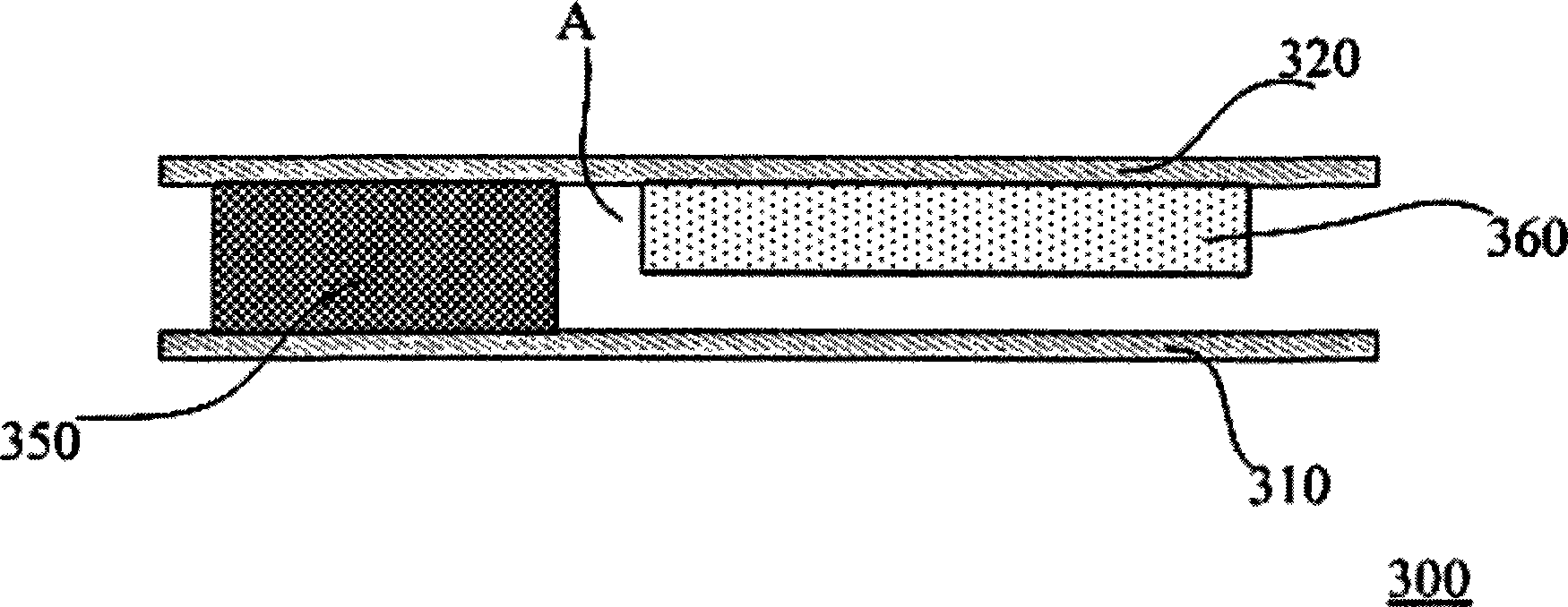

[0035] Figure 4 is a schematic cross-sectional view of a liquid crystal display panel according to a preferred embodiment of the present invention. Figure 5 It is a schematic partial top view of a color filter substrate according to a preferred embodiment of the present invention. Please also refer to Figure 4 and Figure 5 The liquid crystal display panel 400 in the best embodiment of the present invention includes a thin film transistor array substrate 410, a color filter substrate 420, a frame glue 450, a light shielding layer 460, and a thin film transistor array substrate 410 and a color filter substrate. A liquid crystal layer (not shown) between the substrates 420 . The liquid crystal layer is encapsulated in the thin film transistor array substrate 410 and the color filter substrate 420 by the sealant 450 .

[0036] The above-mentioned color filter substrate 420 includes a base 421 and a light-shielding layer 460 , a part of the light-shielding layer 460 is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com