Terminal connection box for optical phase conductor

A technology of optical fiber composite phase line and terminal joint, applied in the direction of fiber mechanical structure, etc., can solve the problems of small cable diameter range, high degradation rate of the first piece of insulator, uneven voltage distribution, etc., and achieve reliable overall sealing, simple structure, and easy installation large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

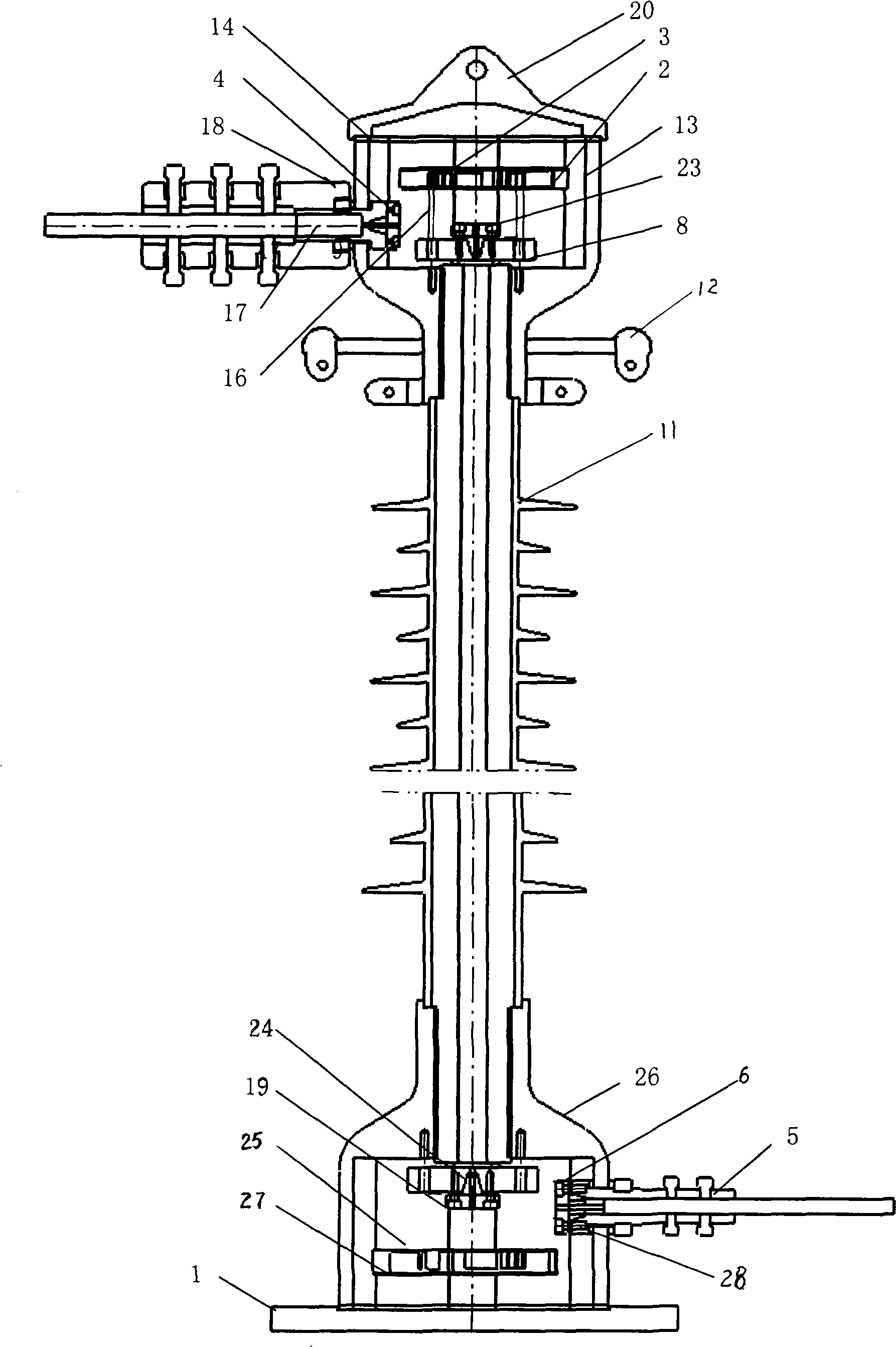

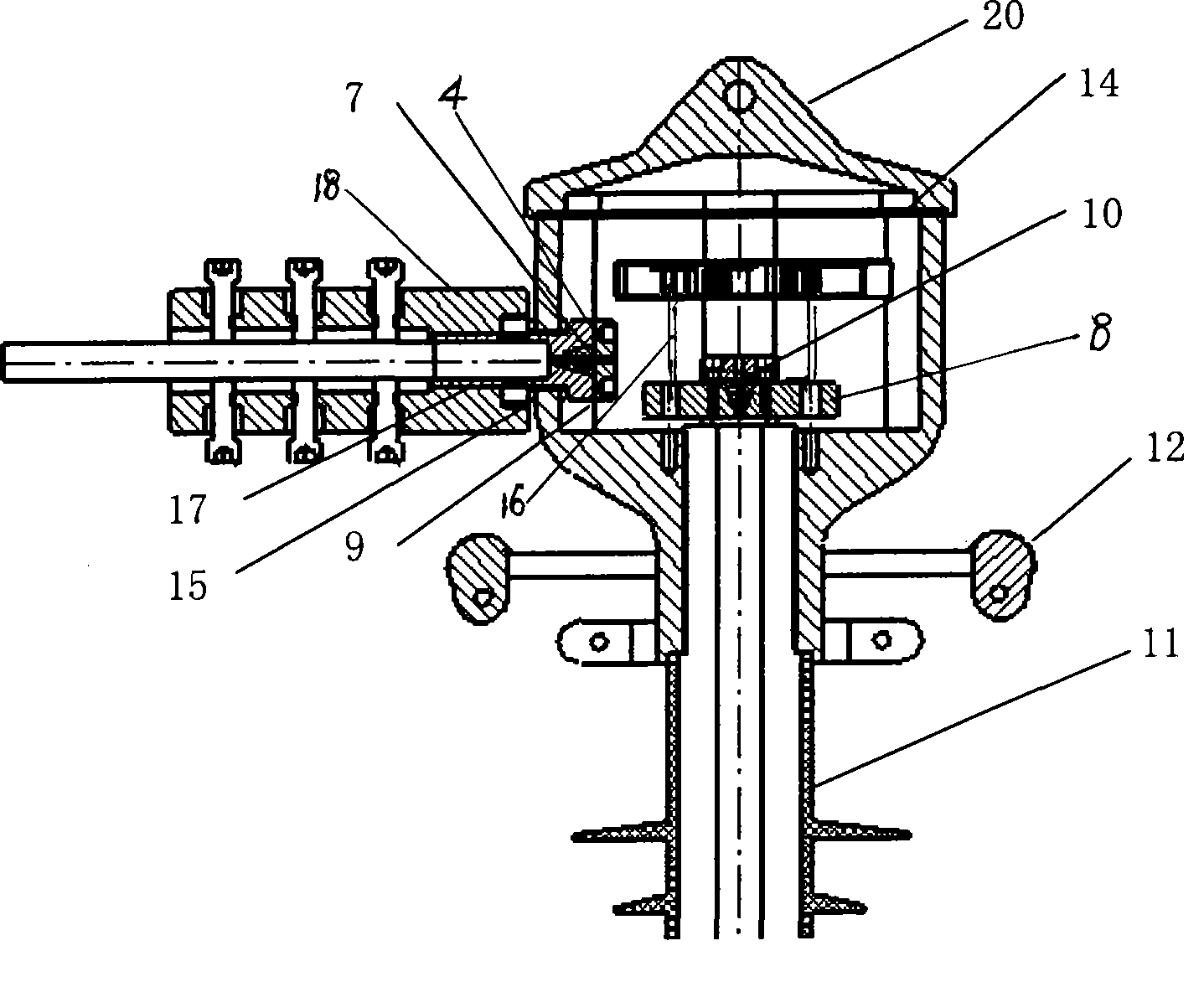

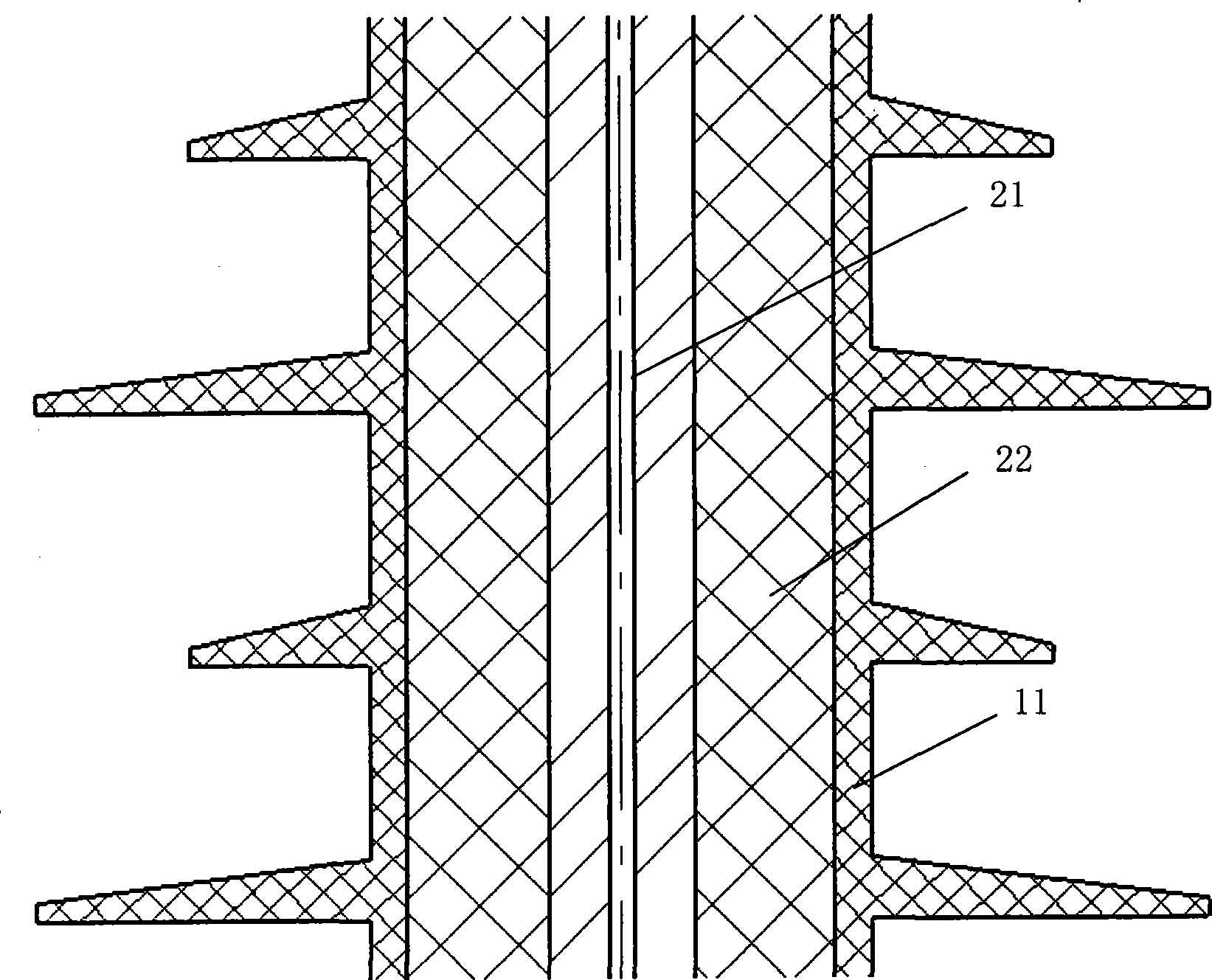

[0013] Refer to attached figure 1 , 2 , 3, the optical fiber composite phase terminal joint box has an upper box body 13 and a lower box body 26, a composite hollow insulator 11 is installed between the upper box body 13 and the lower box body 26, and a composite hollow insulator 11 is installed between the upper box body 13 and the composite hollow insulator 11 A pressure equalizing ring 12 is installed between them; an optical fiber composite phase line (OPPC) clamp 18 is installed on the upper box body 13, and a guide tube 17, a rubber ring 19, and a nut 15 are installed at the cable inlet; inside the cable inlet, It has a rubber cone I7 and a small pressure ring I4; at the bottom of the upper box body, there are a large pressure ring 8, a small pressure ring II23, and a rubber cone II10; a support screw I16, a disk fiber board I2, a disk Fibreboard cover I3; a sealing gasket 14 and an upper cover 20 are installed on the upper part of the upper box body 13; inside the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com