Weighing controlling device and method of electronic belt scale

An electronic belt scale and control device technology, applied in the direction of measuring device, weighing, weighing equipment for continuous material flow, etc. The effect of long service life, increased reliability and metering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

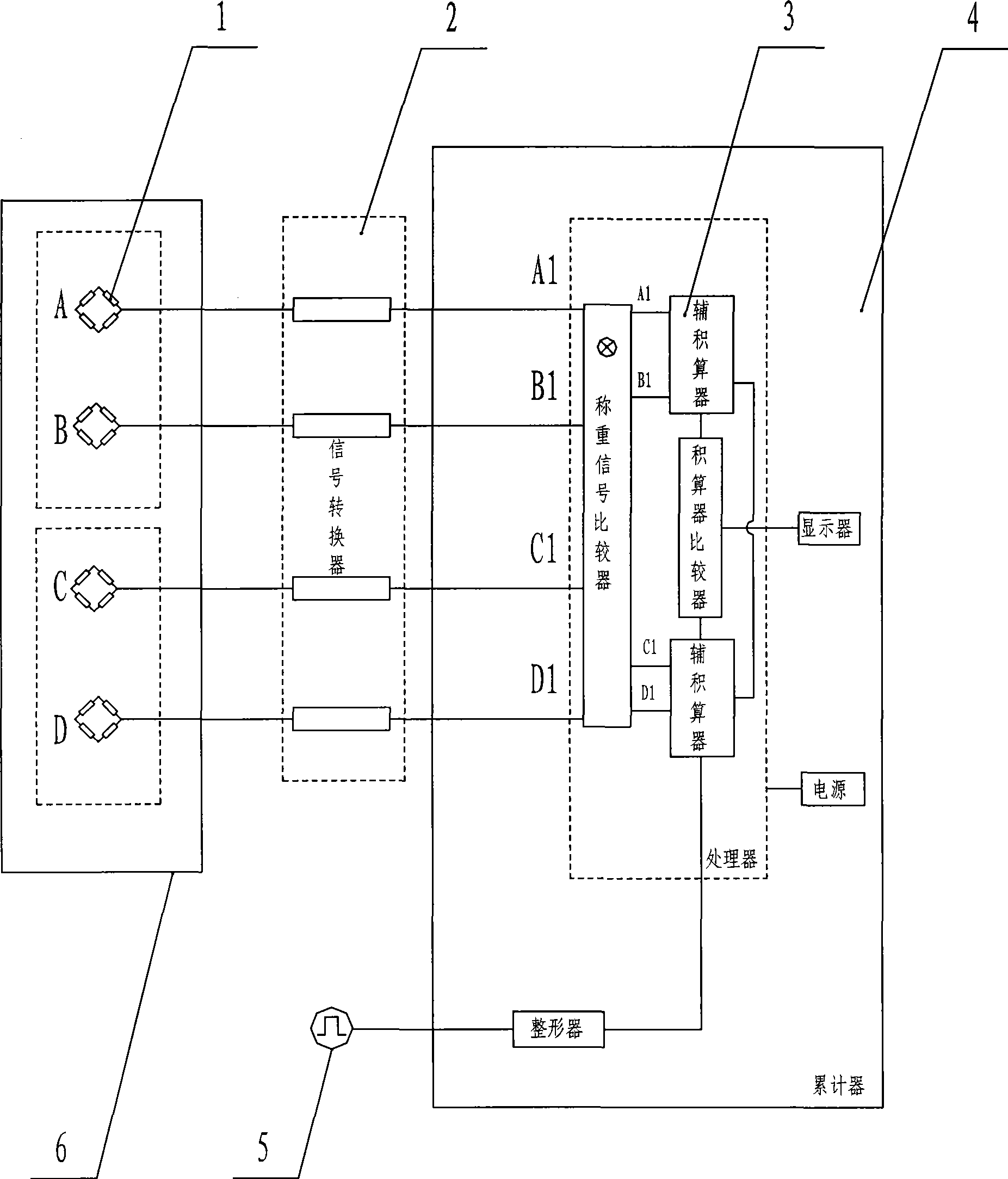

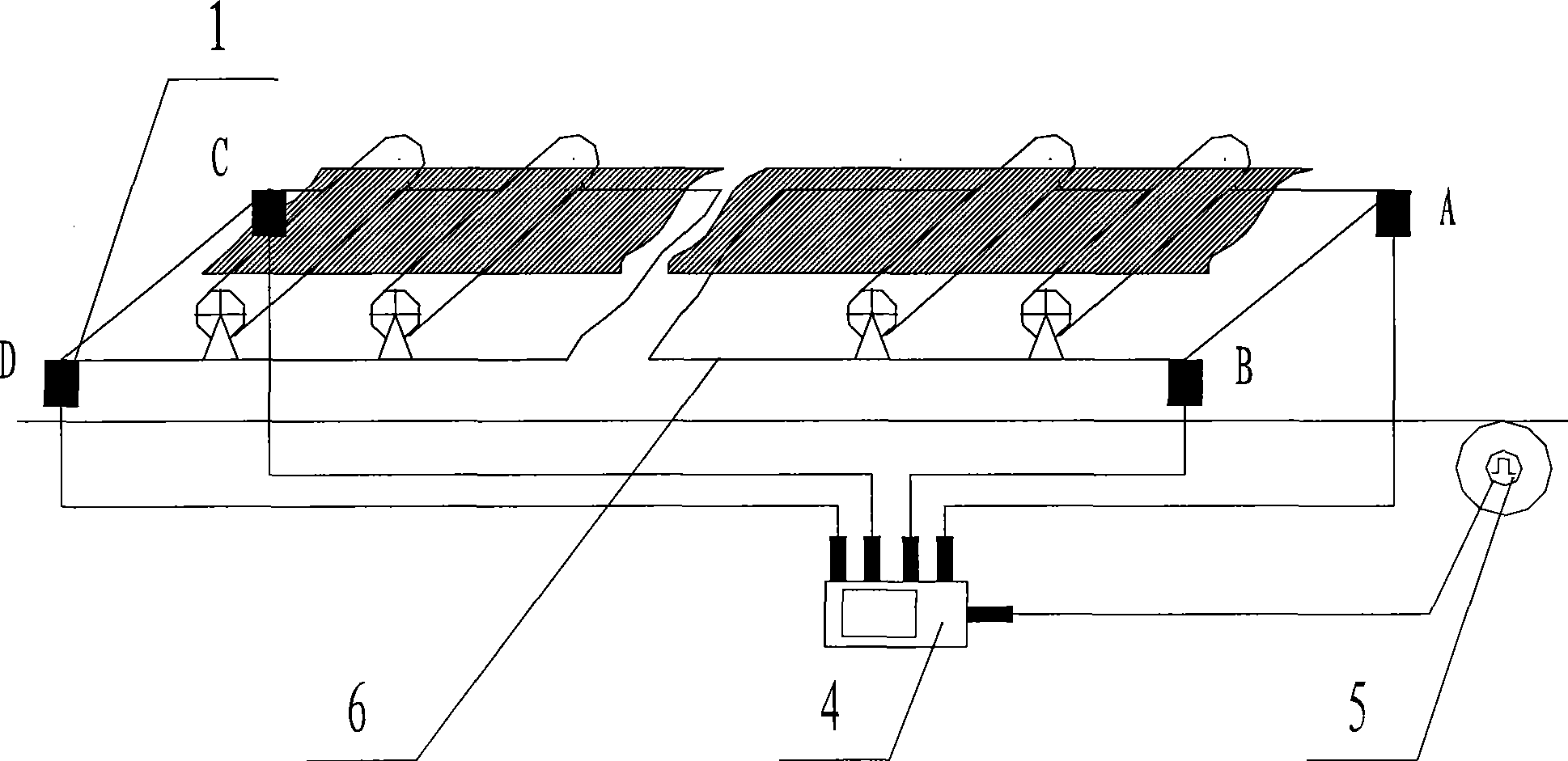

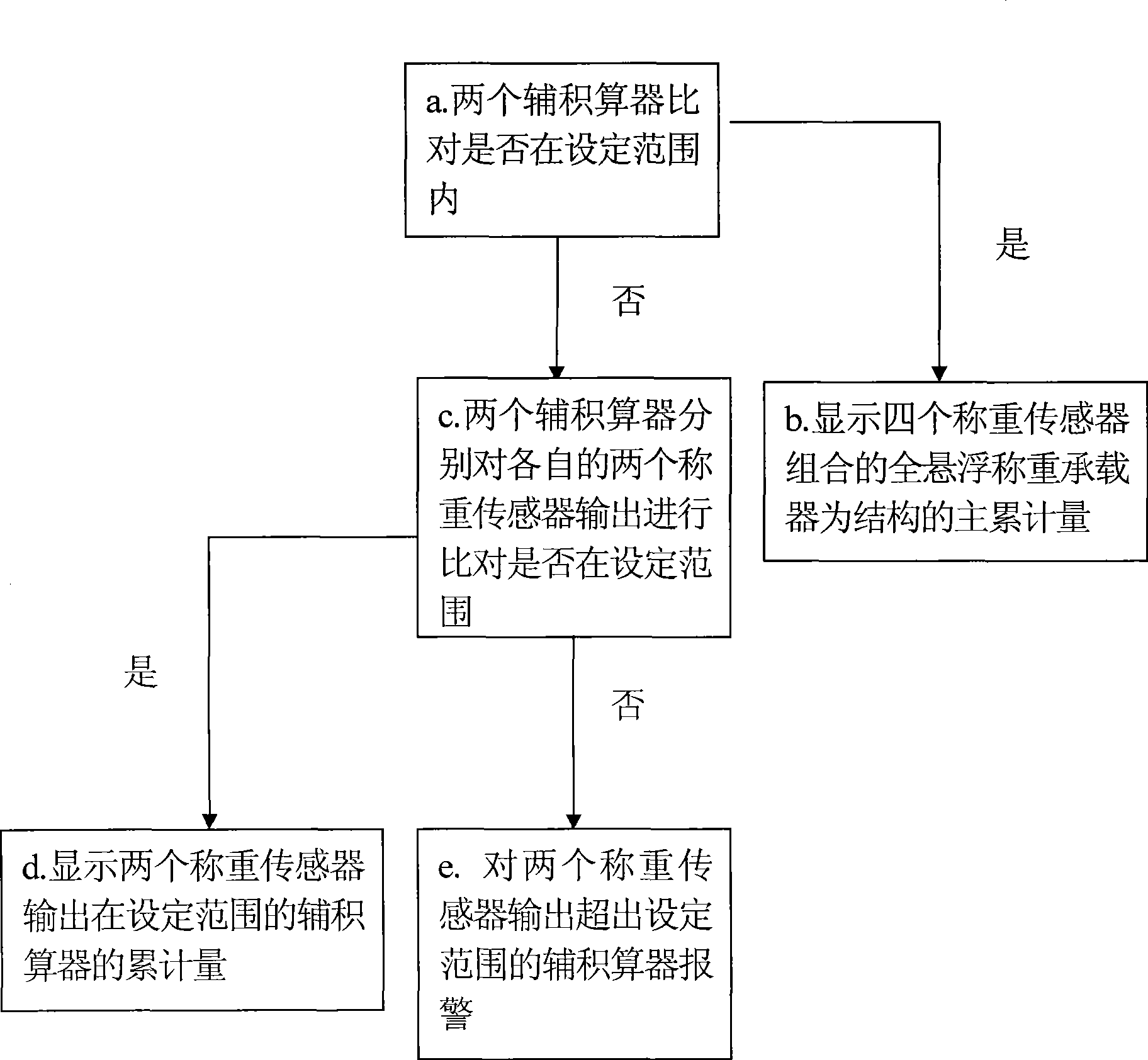

[0019] figure 1 and figure 2 As shown, the weighing control device of the present invention mainly consists of four load cells 1 of A, B, C, and D, a full-suspension weighing carrier 6 supported by four load cells 1, and a displacement sensor 5 And accumulator 4 constitutes. When the load cell 1 is an analog signal sensor, the load cell 1 is connected with a signal converter 2, such as figure 1 Shown; When the load cell 1 is a digital signal sensor, the signal converter 2 is not required. The accumulator 4 mainly includes a processor, a shaper, a memory, a display and a power supply, wherein the signal converter 2 is a 24-bit analog-to-digital conversion circuit AD7710, the processor is a 32-bit CPU integrated circuit S3C44B0X, the memory is an integrated circuit 39VF160, and the displacement signal is shaped The device is an integrated circuit 393,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com