Comprehensive mining hydraulic support mounting transport vehicle

A technology for hydraulic supports and transport vehicles, which is applied in pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of many hidden dangers, labor-intensive and time-consuming hydraulic supports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

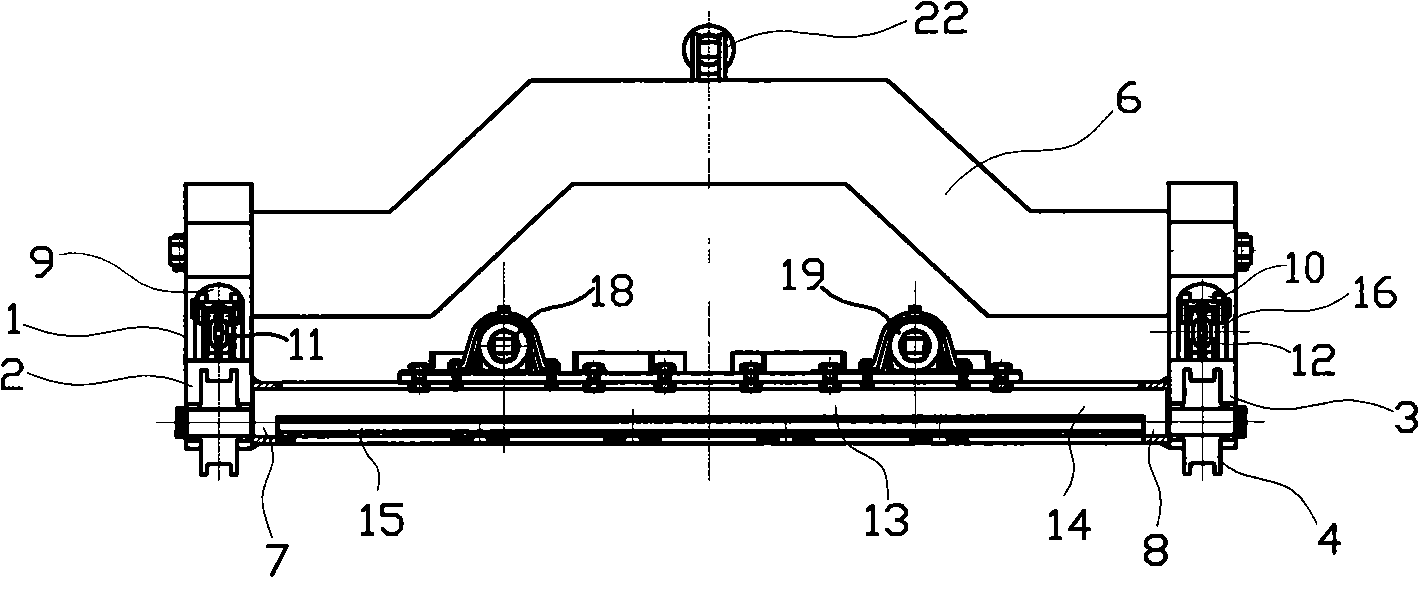

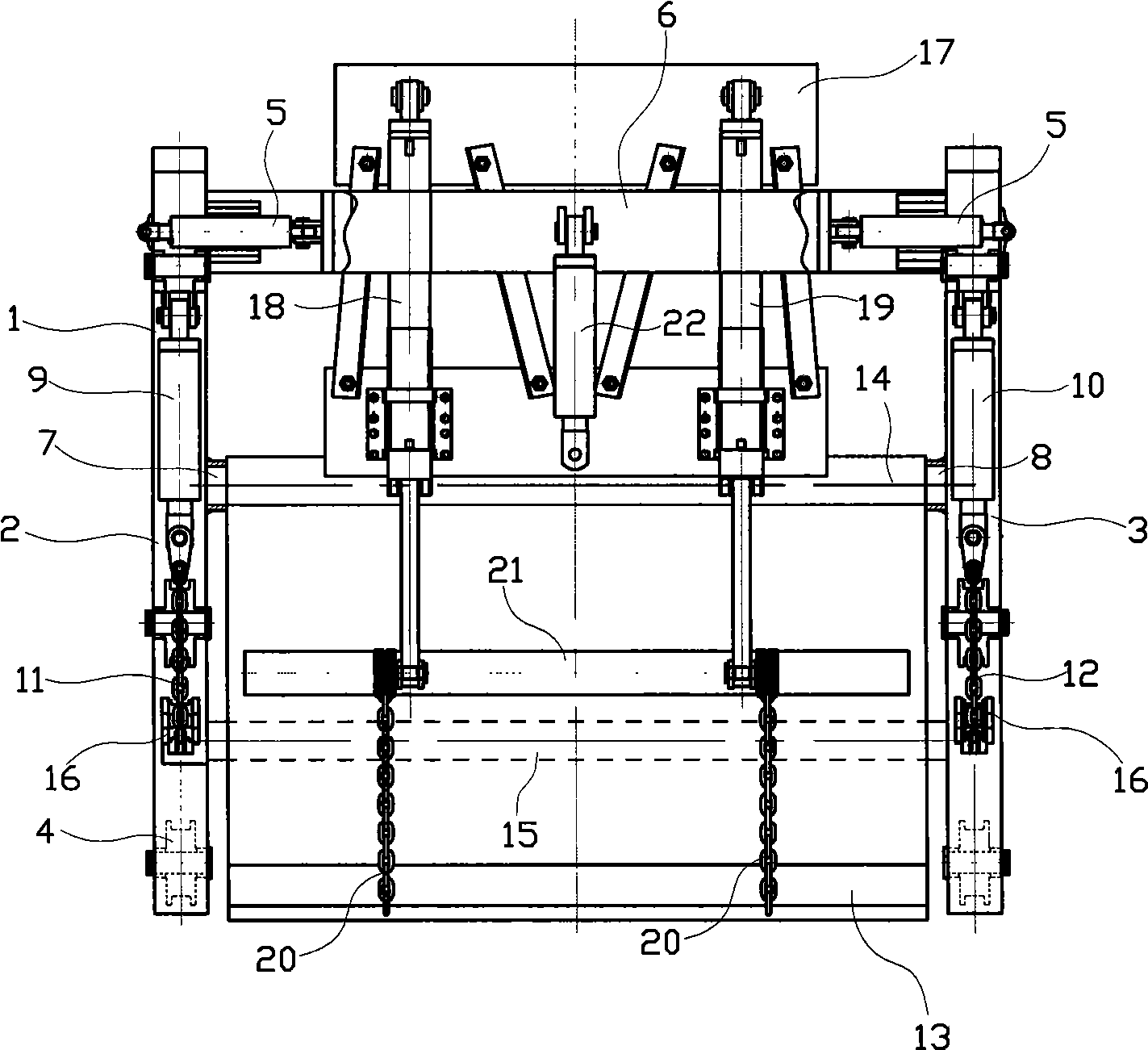

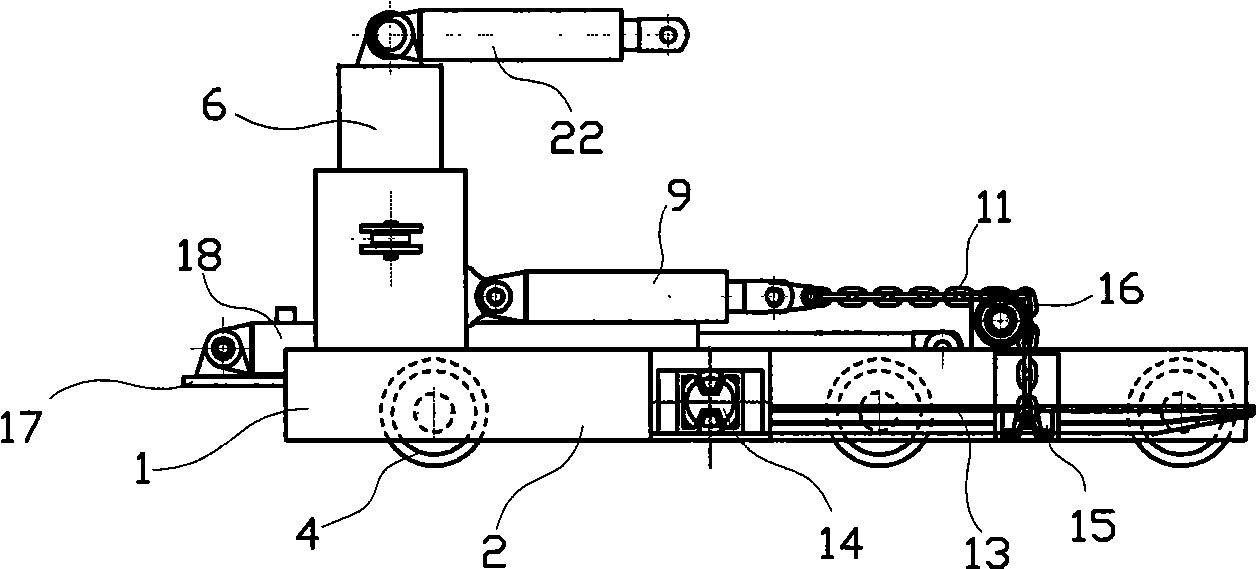

[0016] figure 1 , figure 2 , image 3 Among them, the fully-mechanized mining hydraulic support installation transport vehicle has a vehicle frame 1, and the vehicle frame has two left and right horizontal longitudinal beams 2 and 3 parallel to each other. There are track wheels 4 under the longitudinal beams, and the rear parts of the left and right longitudinal beams are used The rear beam hydraulic cylinder 5 is connected with the rear beam 6, the inner sides of the left and right longitudinal beams are respectively positioned and connected with the relative left and right shaft hole seats 7, 8, and the left and right longitudinal beams are respectively connected with the left and right longitudinal beams. The left and right hoisting hydraulic cylinders 9,10 parallel to the longitudinal beam at the beam rear portion, the piston rods in front of the left and right hoisting hydraulic cylinders are respectively connected with left and right hoisting chains 11,12, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com