Microwave feeder unit used for sealing semiconductor electric absorption modulator

An electro-absorption modulator and semiconductor technology, applied in electrical components, waveguide-type devices, waveguides, etc., can solve the problems of troublesome matching resistors, difficult to test, etc., to avoid high-frequency microwave resonance problems, test simple and practical, and improve Effects of microwave transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0035] Now give a specific embodiment as follows:

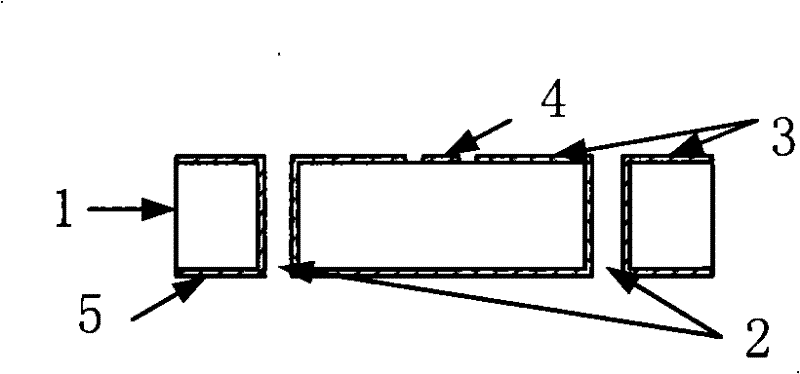

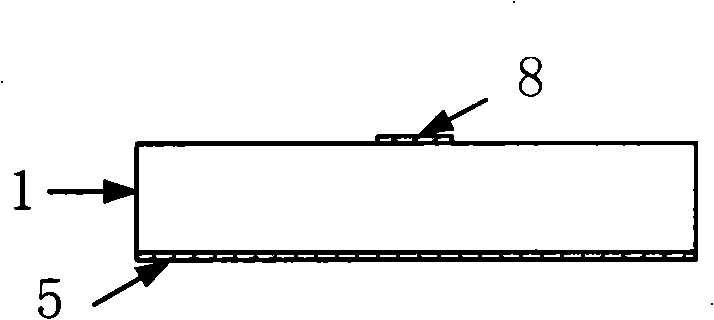

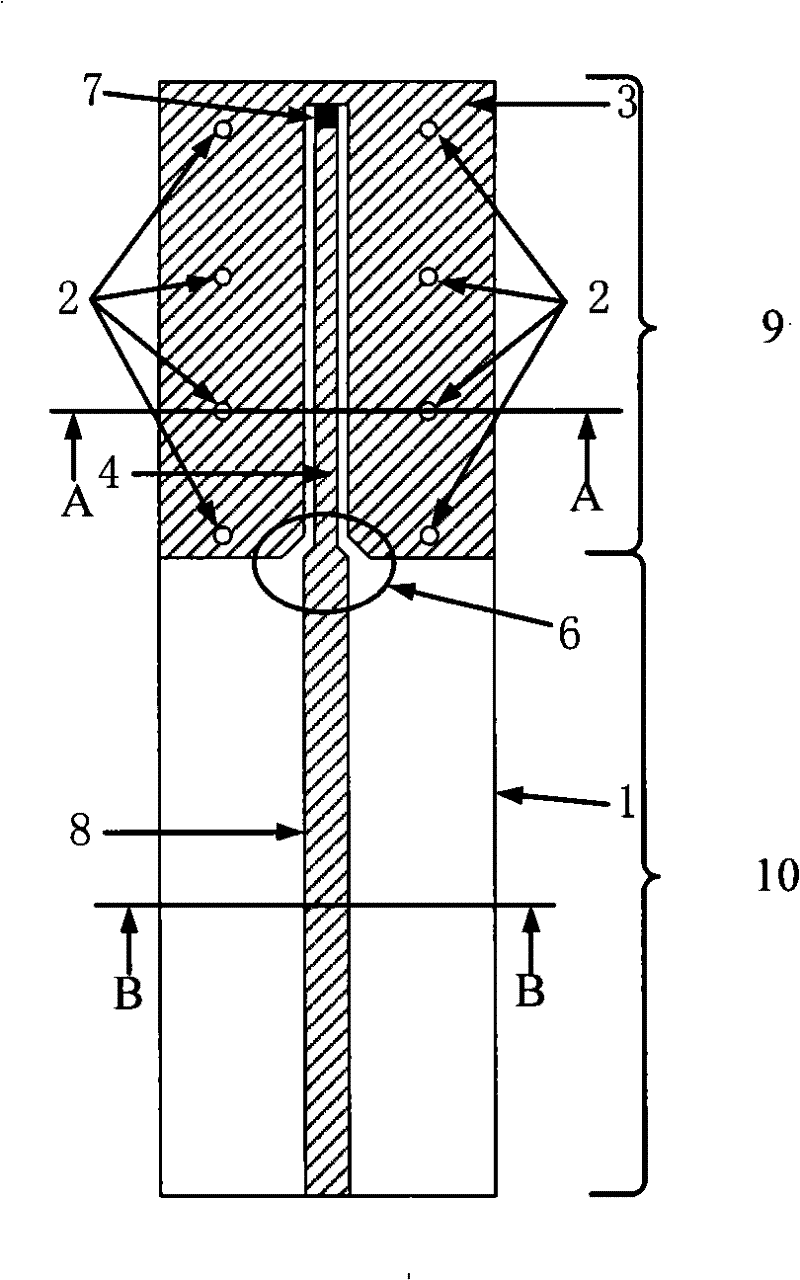

[0036] The heat sink 1 has a relative permittivity of 9.8, a length of 5.5 mm, a width of 1.5 mm, and a thickness of 0.2 mm. The coplanar waveguide signal electrode 4 has a width of 100 μm and a length of 2.4 mm. The interval between them is 50 μm, the width of the microstrip line signal electrode 8 is 200 μm, and the length is 2.85 mm. The joint 6 between the coplanar waveguide and the microstrip line is designed to be at an oblique angle of 135°. There are 8 through holes in the metal electrode 3 , the diameter of the through holes is 0.3mm, the horizontal interval between two adjacent through holes is 0.8mm, and the vertical interval is 0.75mm. The thin film matching resistor 7 is made of tantalum nitride material, with a side length of 100 μm and a resistance value of 50Ω. It can be obtained that the microwave feeder unit for packaging the semiconductor electroabsorption modulator has good transmission characteristics in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com