Firing and explosion prevention high voltage capacitor

A high-voltage capacitor and capacitor technology, applied in capacitors, fixed capacitors, fixed capacitor shells/packages, etc., can solve problems such as high severity requirements, safety accidents, burning, etc., and achieve the effect of avoiding product breakdown damage and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

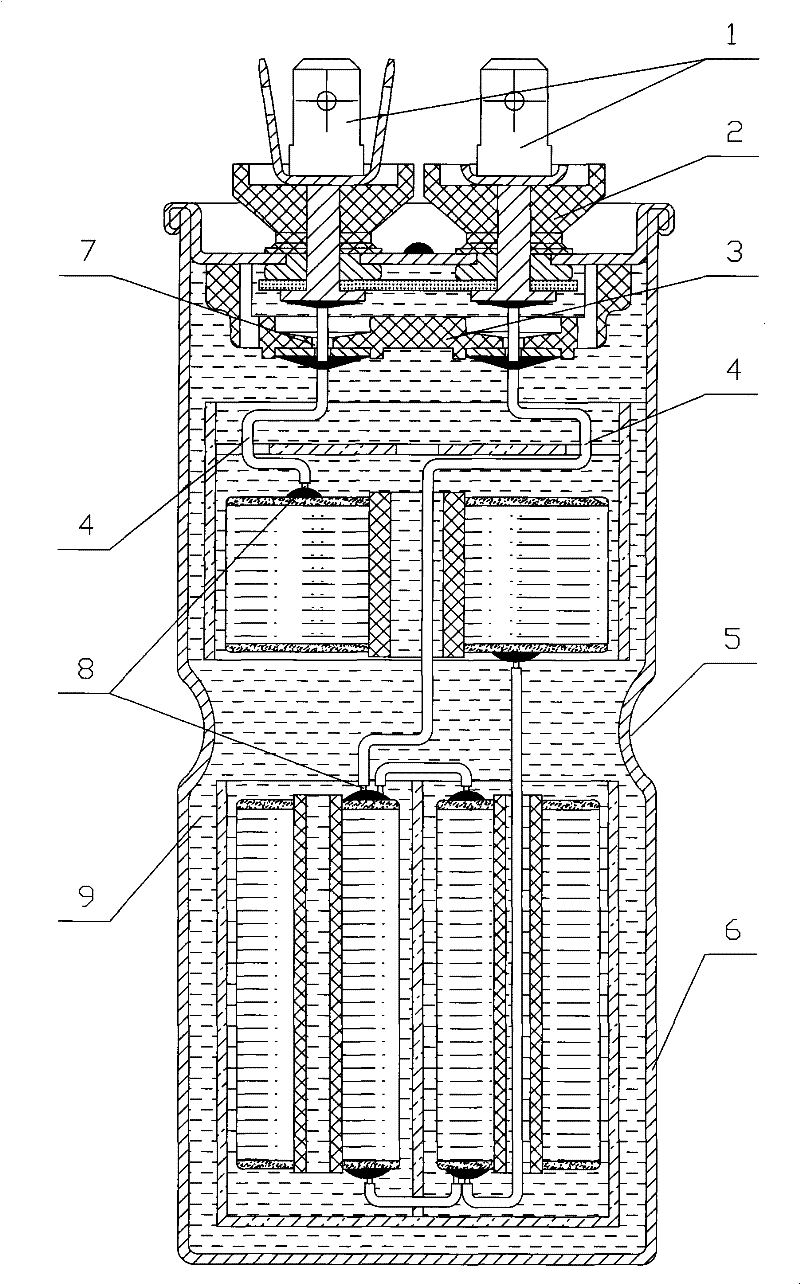

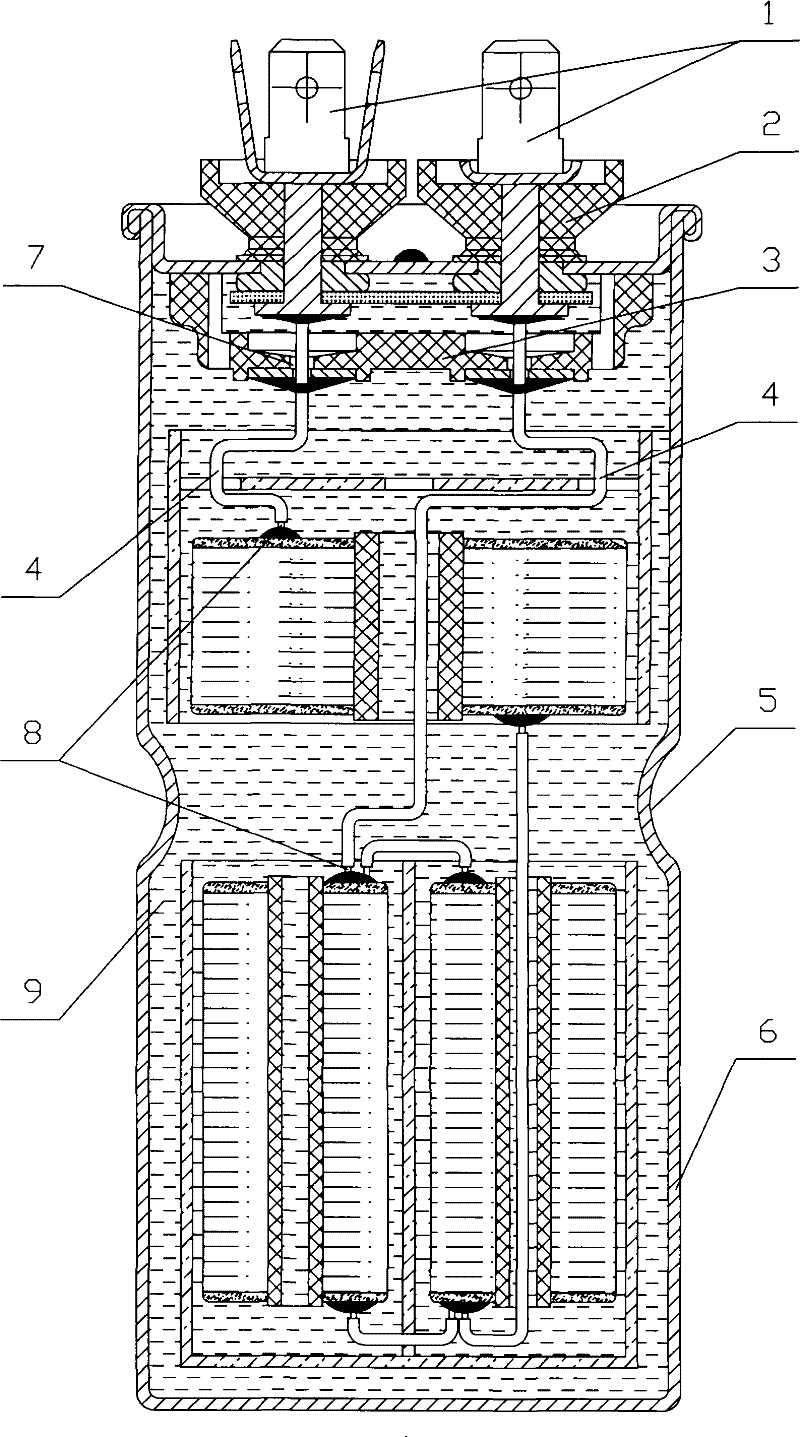

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] It can be seen from the structural schematic diagram of the flame-proof high-voltage capacitor of the present invention shown in the accompanying drawings that it includes a metal-enclosed shell 6, a shell cover assembly 2 with two external terminals 1, and the shell 6 is equipped with parallel and series capacitors. The capacitor core group, the two terminals 8 of the capacitor core group are respectively connected to the two external connection terminals 1 through wires 4 . The inside of the shell 6 is filled with an impregnating liquid 9, and the impregnating liquid 9 is No. 330 methyl silicone oil. The middle part of the shell 6 is provided with an annular groove 5 along the circumference of the shell 6 . The shell 6 is made of aluminum.

[0015] The capacitor core group is divided into three unit cores, wherein two unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com