On-line monitoring device and method of weighting sensors

A technology of a load cell and a monitoring device, which is applied in the field of online monitoring of load cell failures in a weighing system, can solve problems such as inability to accurately analyze sensor failures, inaccurate measurement, economic losses, etc., achieve wide practicability, improve measurement Accurate, easy-to-maintain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

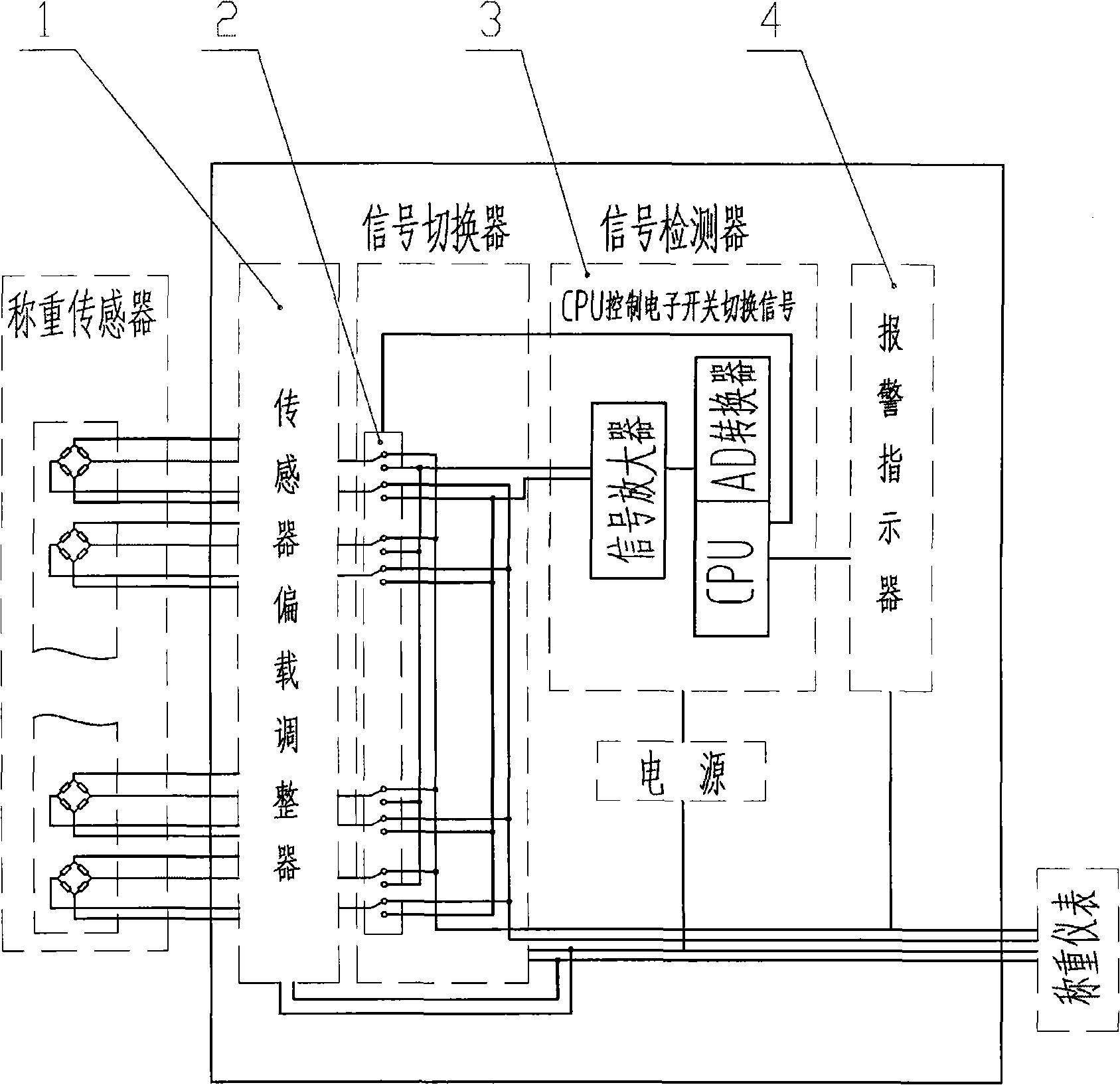

[0011] figure 1 The load cell online monitoring device shown is composed of a sensor eccentric load regulator 1 connected to the load cell, a sensor eccentric load regulator 1 connected to a signal detector 3 and a signal switcher 2 connected to a weighing instrument, and a signal detector 3 connected 4. The alarm indicator is composed of a power supply circuit, and the software part includes the program run by the microcontroller. Each adjustment circuit in the sensor eccentric load regulator 1 is composed of a variable resistor. By adjusting the variable resistor, the signals output by each load cell are basically consistent. In a weighing system composed of 4 or 6 load cells, the signal switcher 2 is composed of 8 or 12 reed relays, two for each circuit. The switching speed of the magnetic reed relay is fast, which can reach one switch per 1ms, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com