Method for measuring inside and outside diameter deflection of soft bearing retainer by means of three-point fix circle-formation

A bearing cage and three-point positioning technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of soft cage inner and outer diameter deviation measurement that have not been reported, and the results are inaccurate and reliable, so as to improve the measurement efficiency and the accuracy of measurement, the method is simple and novel, and the effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The soft bearing retainer referred to in the present invention includes bearing retainers made of resin, engineering plastics and special materials, and can also be used for various bearing retainers made of metal.

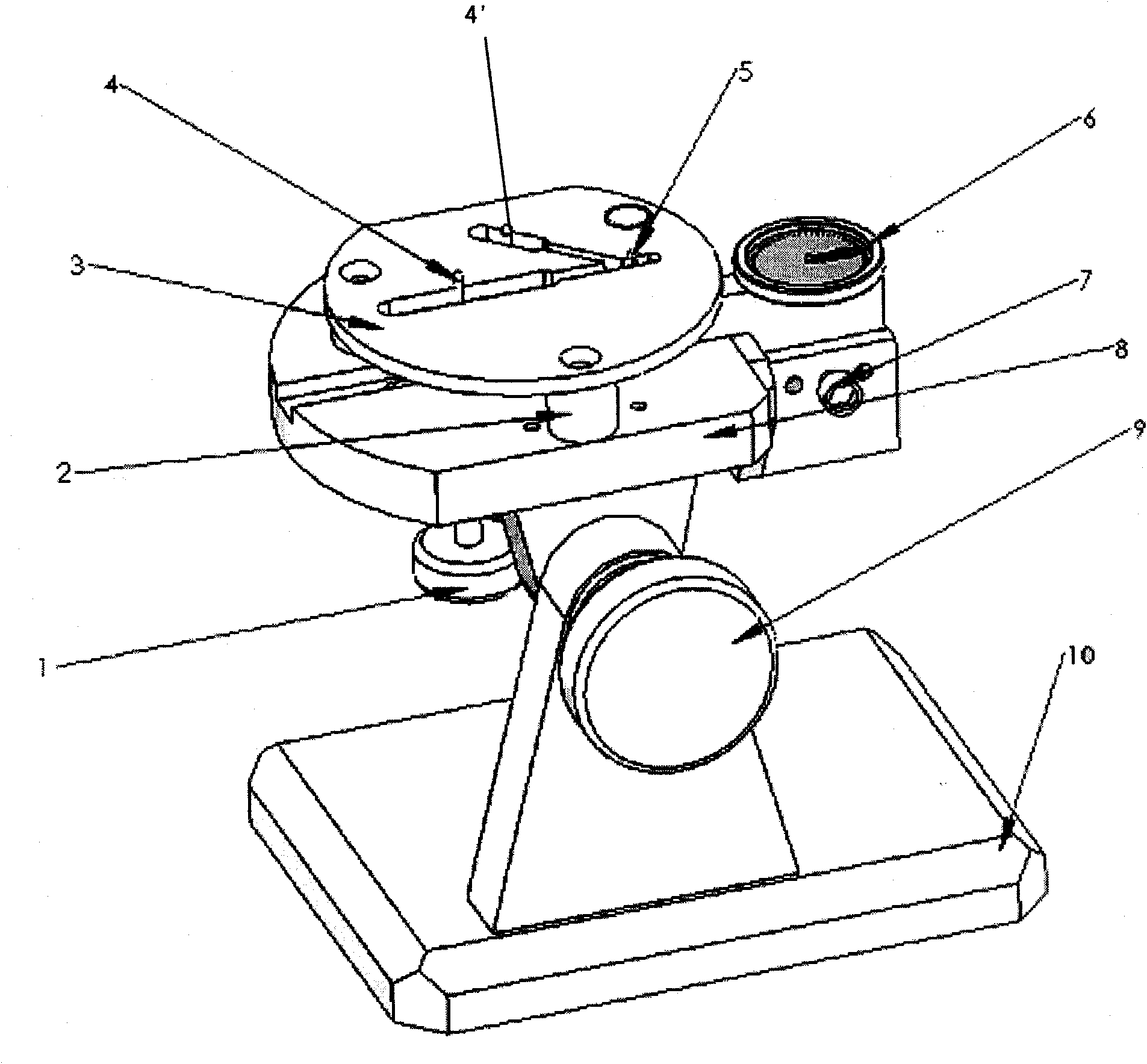

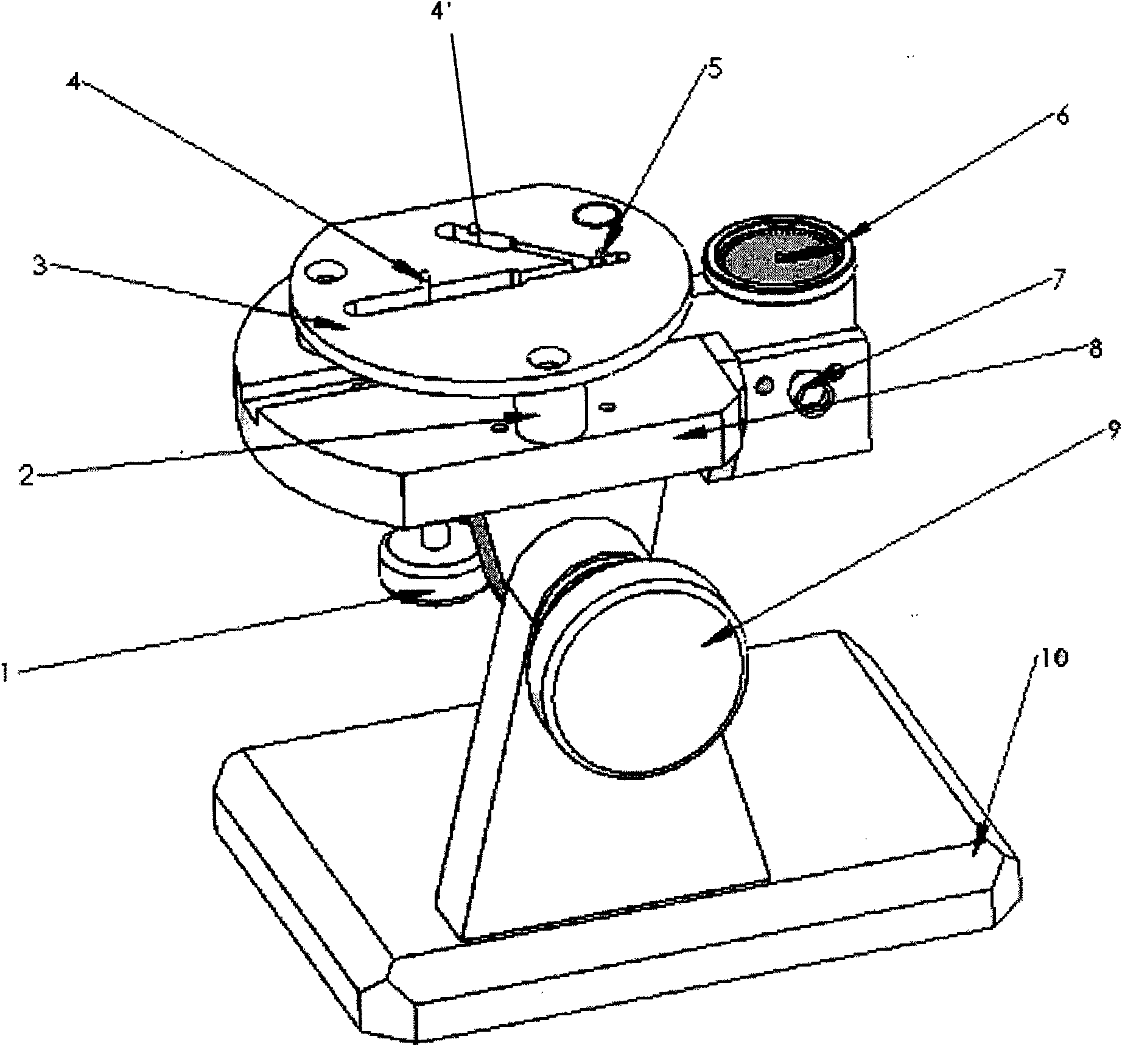

[0018] combine figure 1 , the method for measuring the deviation of the inner and outer diameters of the soft bearing cage by three-point positioning in a circle according to the present invention uses the principle of three-point positioning in a circle to measure the deviation of the inner and outer diameters of the soft bearing cage. The principle of three-point positioning into a circle is to place the soft bearing holder flat on the measurement base plate 3. The measurement base plate 3 is provided with an equilateral triangle and a "herringbone"-shaped chute. The common top of the chute is equipped with a slight movement The measuring head plate 5, the first spherical fulcrum 4 and the second spherical fulcrum 4' moving along the chute are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com