Automatic analyzer

A technology of automatic analysis device and degassing device, which is applied in the direction of analysis materials, instruments, biological tests, etc., can solve the problems of decreasing the concentration of surfactants, reducing the effect of inhibiting the reproduction of bacteria, and eliminating the occurrence and stability of microbubbles. The effect of metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

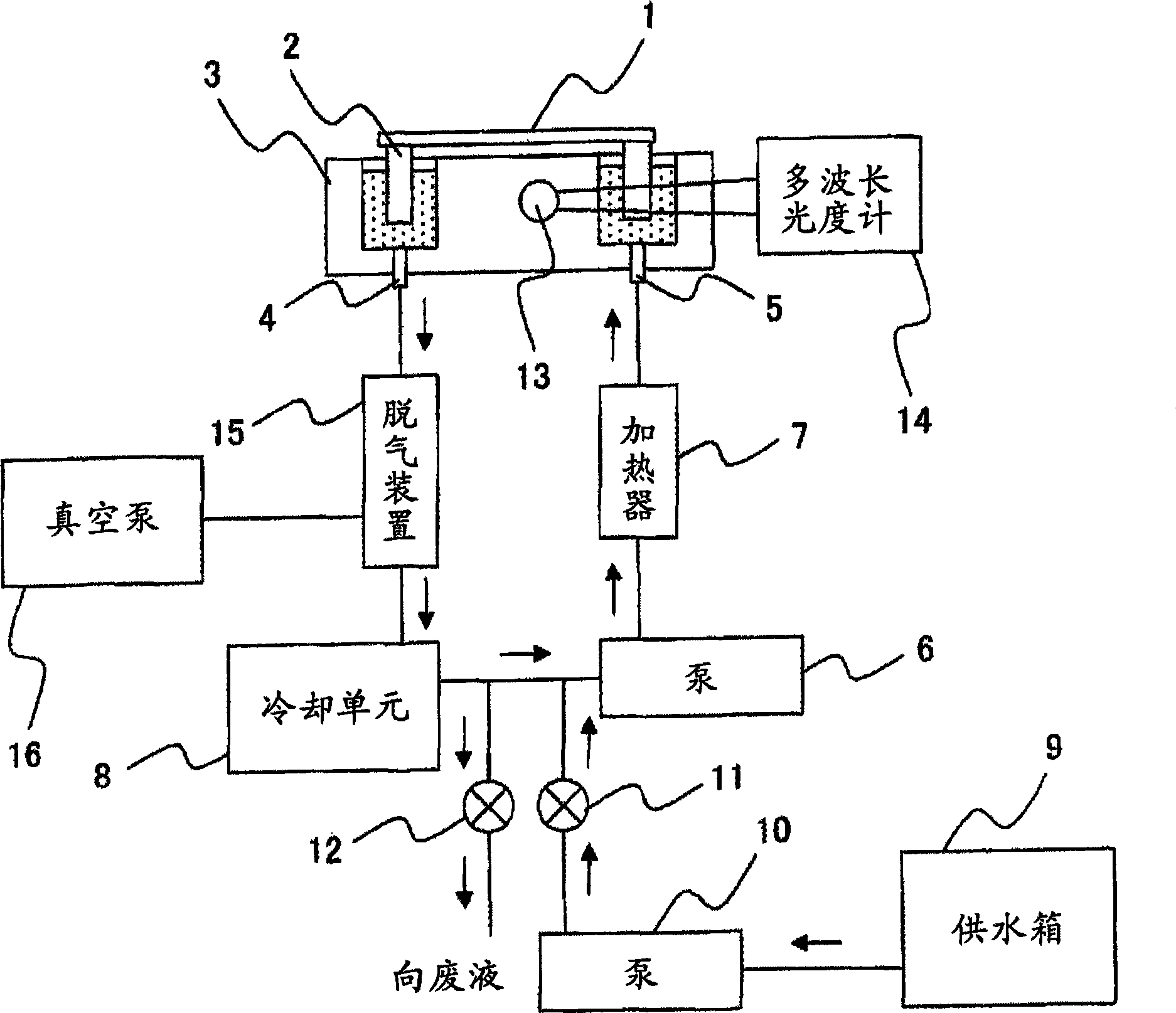

[0019] figure 1 It is a block diagram showing an embodiment of a hot water circulation type reaction tank using the automatic analyzer of the present invention. The reaction vessel 2 mounted on the circumference of the circular reaction disk 1 is immersed in the liquid held in the same circular reaction tank 3 . The liquid in the reaction tank is always circulated by the circulation pump 6 provided between the discharge pipe 4 and the supply pipe 5, and the temperature is controlled by on / off control of the heating moxa. Thereby, the reaction liquid held inside the reaction vessel 2 is kept at an optimum temperature (for example, 37° C.) required for the reaction. The liquid in the reaction tank can be water or other solutions. In addition, when the temperature of the liquid in the reaction tank is too high, a cooling unit 8 for cooling the liquid may be provided. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com