Device and method for measuring embedding depth of proppant

A technology of embedding depth and measuring devices, which is applied in the directions of surveying, earthwork drilling, and mining fluids, etc. It can solve problems such as inability to obtain embedding depth, poor adaptability of experimental results, and inability to repeat experiments on rocks in different formations, so that the measurement method is practical , Simple structure, reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

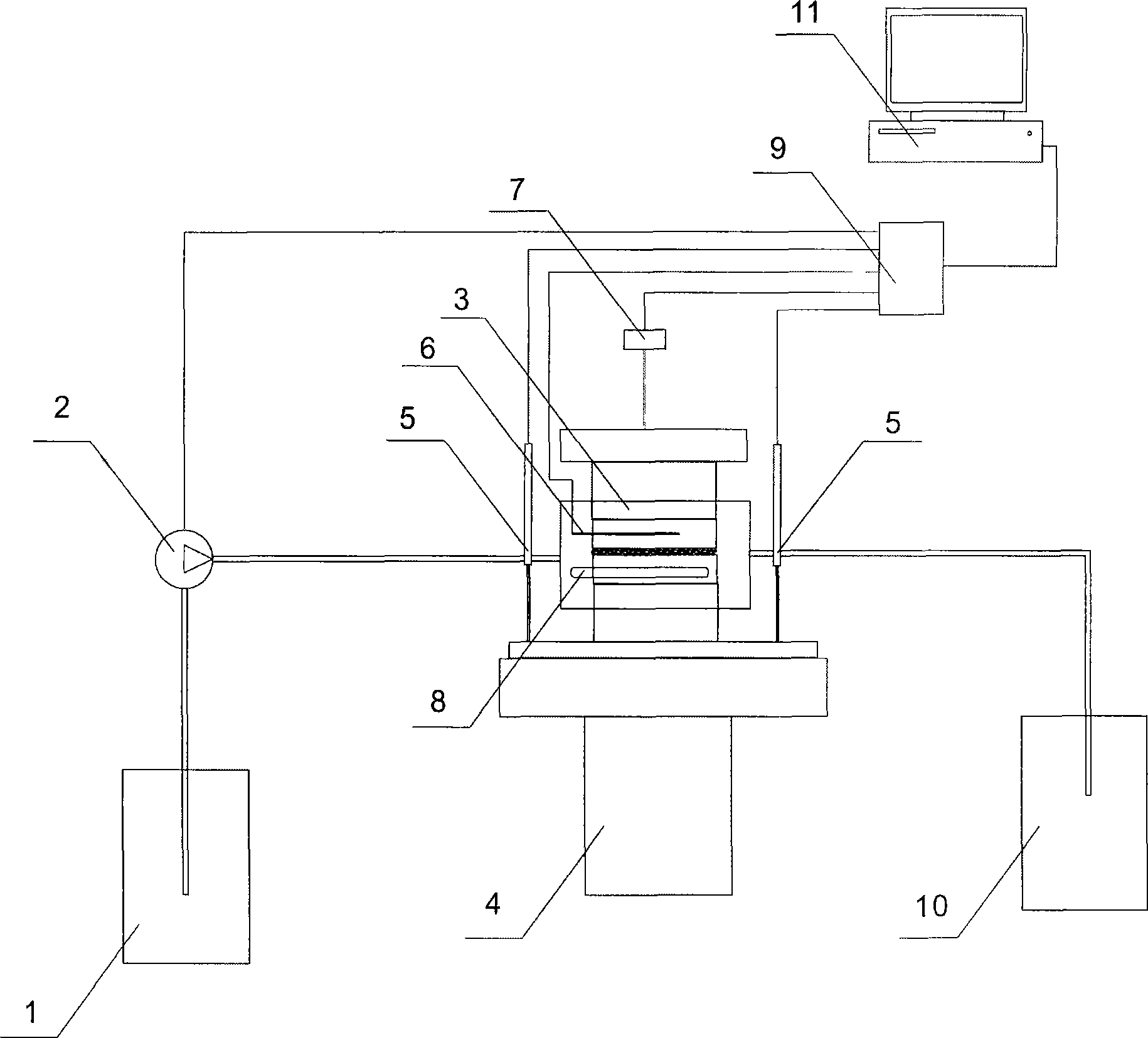

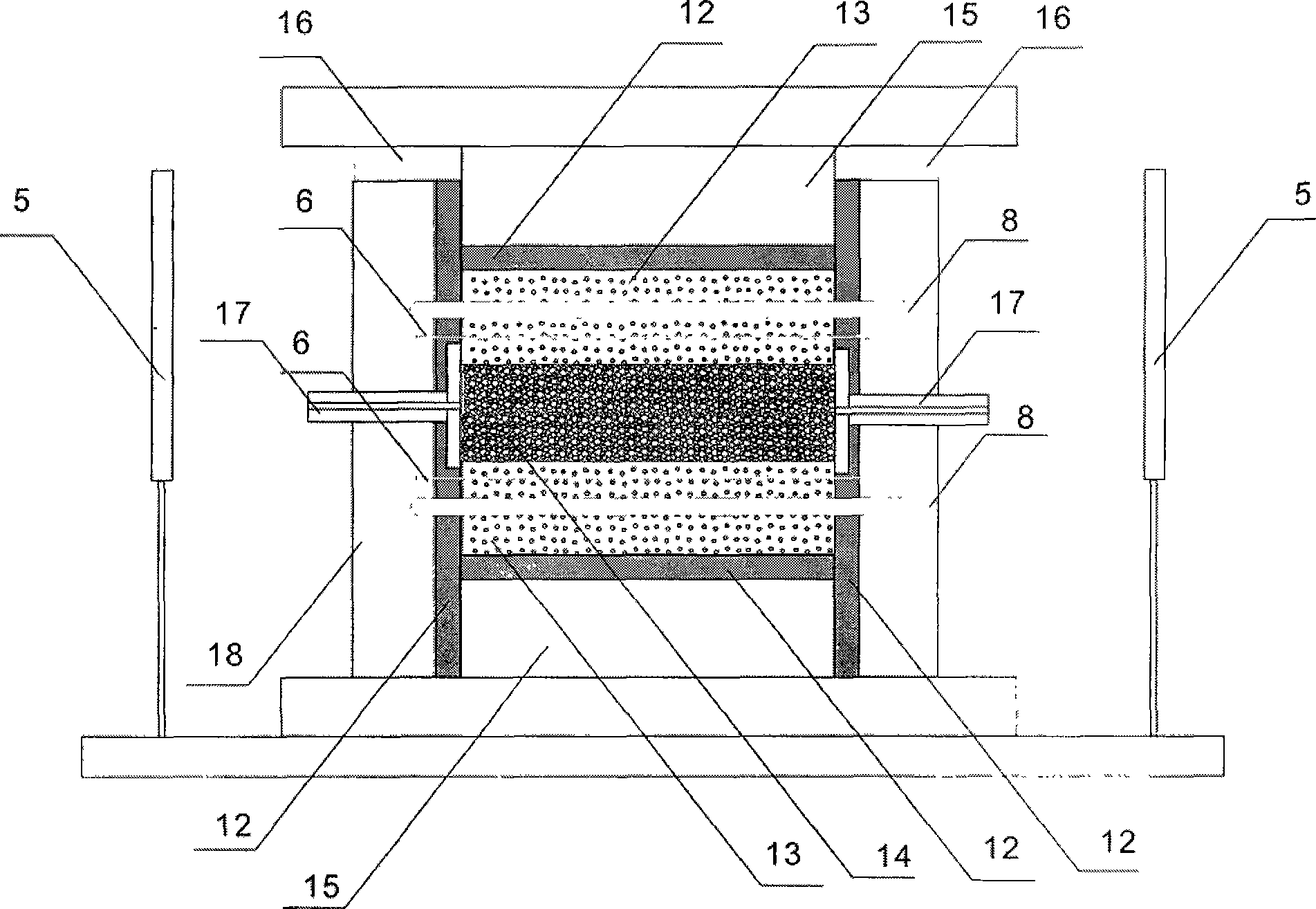

[0025] see figure 1 , figure 2 . The measuring device for the depth of proppant embedding is mainly composed of an advection pump 2, a plate holder 3, a hydraulic press 4, a data acquisition board 9, and a computer 11. The plate holder 3 is located on the platform of the hydraulic press 4, and the plate clamps The container is a hollow container with a piston 15 at the upper and lower sides of the cavity 18. There are rock cores (or steel plates) 13 between the pistons, and proppant 14 is arranged between the rock cores. There are sealing gaskets 12 around the rock cores. There is also a sealing gasket 16 between the piston and the cavity; there are deep holes inside the cavity of the flat plate holder for inserting the electric heating rod 8 and the temperature sensor 6, and there are small holes 17 for entering and exiting the experimental fluid at both ends respectively. The liquid small hole is connected with the advection pump 2 and the liquid storage tank 1, and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com