Technological method for transforming fuel alcohol in stages and cogenerating electricity and paper pulp with pennisetum hydridum

A technology of fuel ethanol and process method, applied in the field of comprehensive utilization of royal bamboo grass resources, to achieve the effects of saving resources, increasing the degree of dispersion, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

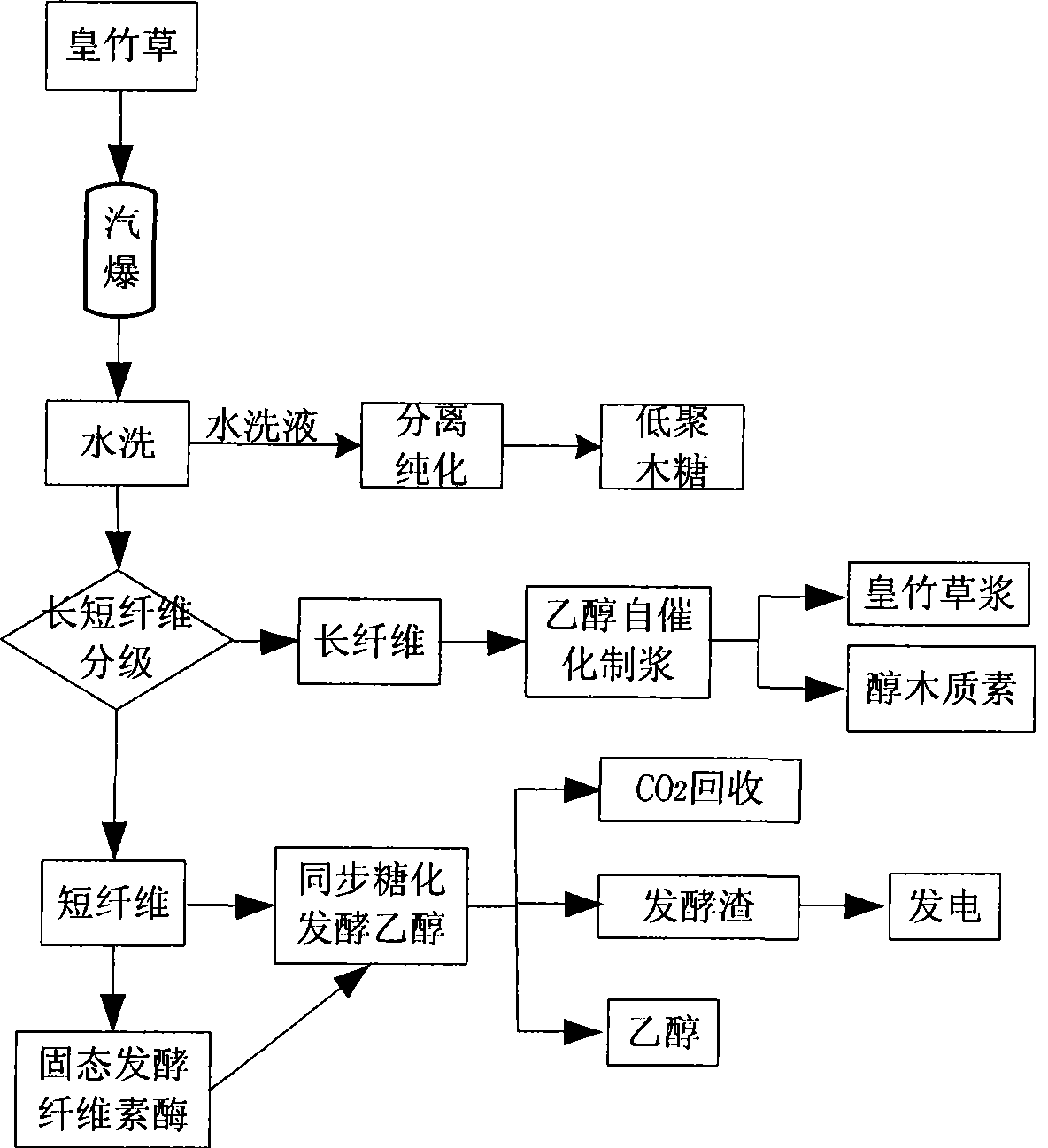

Method used

Image

Examples

Embodiment 1

[0026] Example 1: ① steam explosion treatment: Cutting the Phyllostachys japonica into sections, using a steam explosion device to maintain the pressure at a pressure of 1.5 MPa for 3 minutes to carry out steam explosion treatment on the Phyllostachys japonica.

[0027] ② Preparation of xylo-oligosaccharides: the steam-exploded Bamboo Grass was washed with water, and the washing solution was degraded hemicellulose for the preparation of xylo-oligosaccharides.

[0028] ③Classification of long and short fibers: long fibers (fiber length greater than 3 centimeters) and short fibers (fiber length less than 3 centimeters) are obtained by classifying and carding the steam-exploded bamboo grass.

[0029] ④Long fiber pulping: After carding, the long fiber is made of ethanol with a concentration of 60% and a solid-to-liquid ratio of 1 / 10 (g / ml). At 160° C., heat preservation for 2 hours, extraction and delignification, to obtain coarse pulp. Then adopt two-stage bleaching technology, t...

Embodiment 2

[0038] Example 2: ① steam explosion treatment: Cutting the Phyllostachys japonica into sections, using a steam explosion device to maintain the pressure at a pressure of 1.5 MPa for 4 minutes to carry out steam explosion treatment on the Phyllostachys praecox.

[0039] ② Preparation of xylo-oligosaccharides: the steam-exploded Bamboo Grass was washed with water, and the washing solution was degraded hemicellulose for the preparation of xylo-oligosaccharides.

[0040] ③Classification of long and short fibers: long fibers (fiber length greater than 3 centimeters) and short fibers (fiber length less than 3 centimeters) are obtained by classifying and carding the steam-exploded bamboo grass.

[0041] ④Long fiber pulping: After carding, the long fiber is made of ethanol with a concentration of 60% and a solid-to-liquid ratio of 1 / 10 (g / ml). At 160° C., heat preservation for 2 hours, extraction and delignification, to obtain coarse pulp. Then adopt two-stage bleaching technology, th...

Embodiment 3

[0052] Example 3: ① steam explosion treatment: Cutting the Phyllostachys japonica into sections, and using a steam explosion device to maintain the pressure at a pressure of 1.5 MPa for 5 minutes to carry out steam explosion treatment on the Phyllostachys praecox.

[0053] ② Preparation of xylo-oligosaccharides: the steam-exploded Bamboo Grass was washed with water, and the washing solution was degraded hemicellulose for the preparation of xylo-oligosaccharides.

[0054] ③Classification of long and short fibers: long fibers (fiber length greater than 3 centimeters) and short fibers (fiber length less than 3 centimeters) are obtained by classifying and carding the steam-exploded bamboo grass.

[0055] ④Long fiber pulping: After carding, the long fiber is made of ethanol with a concentration of 60% and a solid-to-liquid ratio of 1 / 10 (g / ml). At 160° C., heat preservation for 2 hours, extract and delignify, and obtain coarse pulp. Then adopt two-stage bleaching technology, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com