Double-motor skidproof differential drive axle of electric automobile

A differential drive, electric vehicle technology, applied in vehicle components, control devices, transportation and packaging, etc., can solve problems such as vehicle impossibility, waste of motor drive power for slipping wheels, etc., to facilitate vehicle layout and improve dynamic performance. , the effect of reducing the size of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

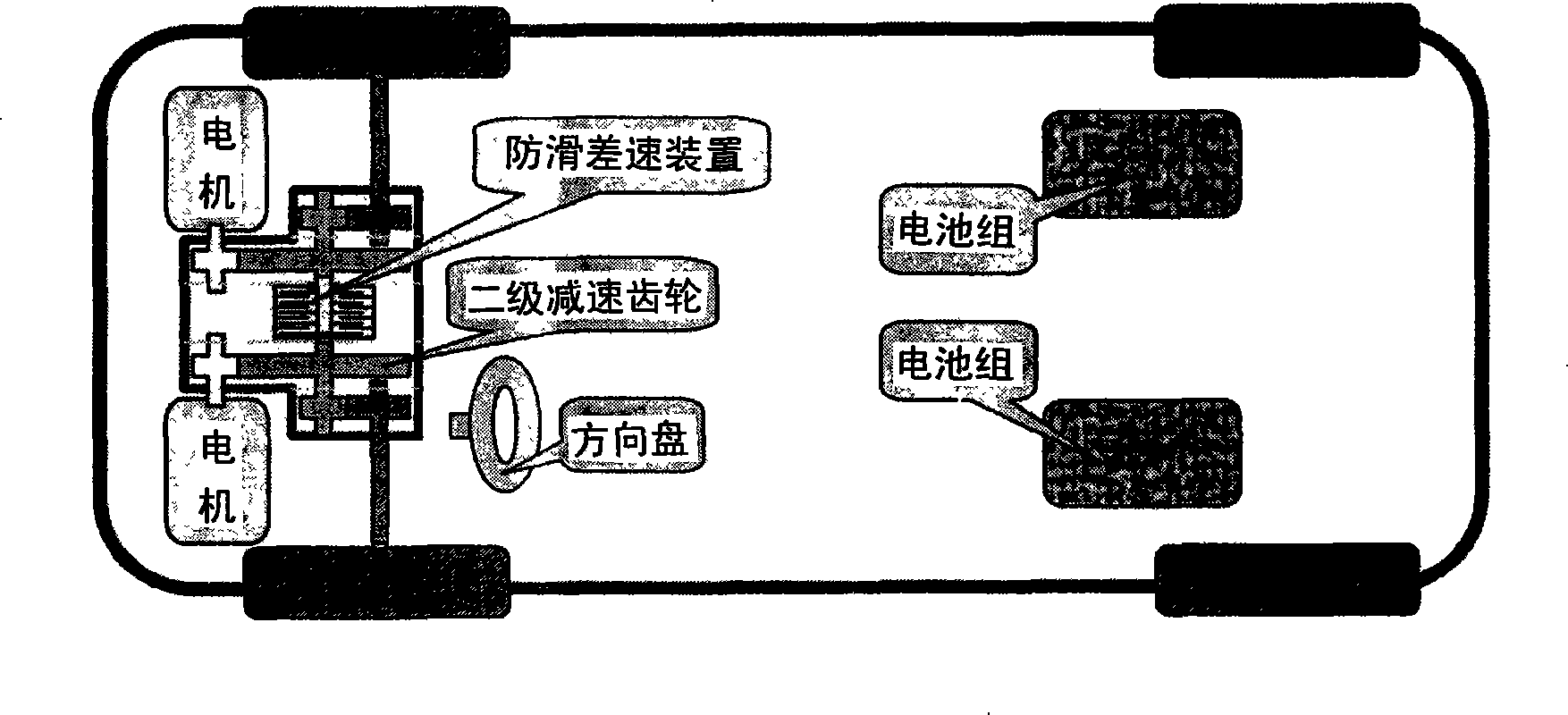

[0032] Such as figure 2As shown, the present invention is based on the following principles: a combined structure of double high-speed motors and two-stage reducers is adopted, and half-shaft transmission is adopted, and an anti-slip differential device is installed in the reduction gear box. When driving, the anti-skid differential device can be used to use the high adhesion of the ground on the other side to assist in controlling the slip, and play the role of the ASR (drive anti-skid) part. When the wheel speed difference is large, the non-slip differential device automatically realizes the flexible combination of the transmission gears on both sides, which improves the passing performance of the vehicle.

[0033] A specific embodiment of the dual-motor anti-slip differential drive axle according to the present invention will be described in detail below with reference to the accompanying drawings.

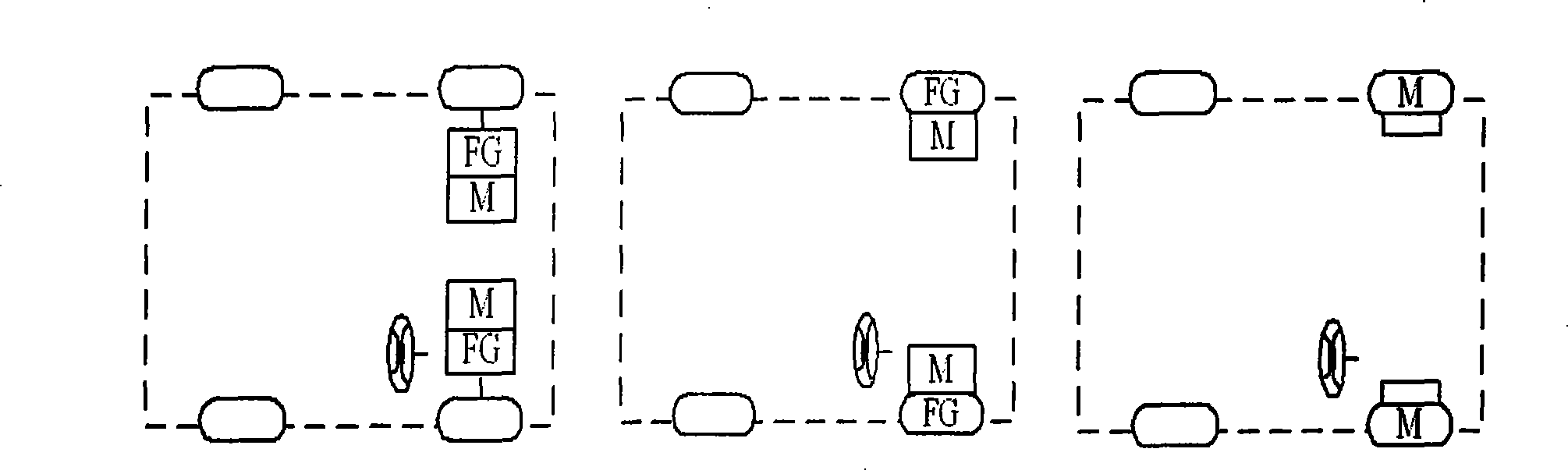

[0034] Figure 3-1 , 3-2 , 3-3, 3-4 are the appearance diagrams showin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com