Air hose joint device for breathe

A joint device and air hose technology, which is applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, connection with fluid cut-off device, etc., can solve problems such as sleeve mouth leakage, and achieve good sealing and good The effect of tightness, docking and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

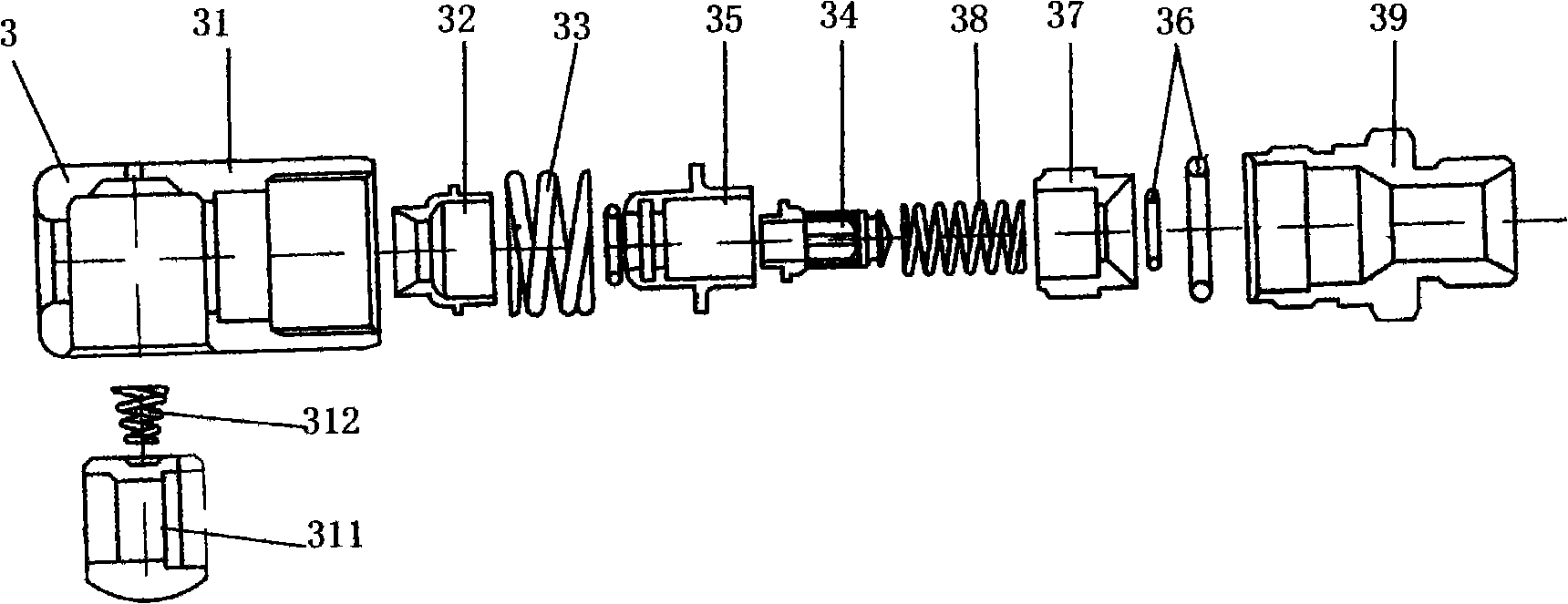

[0028] exist figure 1 In the joint shell 1, the center of the joint 11 and the hose joint 18 is formed with a through hole, and the hose joint 18 is covered with a protective cover 19 made of metal, and the joint is also formed with a longitudinal through hole communicating with the round hole. The switch 111 is sealed and fixed in the through hole, and the chamber tower spring 112 is placed in the switch. Put the switch card 12, ○-shaped sealing ring 13, valve core 14, ○-shaped sealing ring 13, pin 15, ○-shaped sealing ring 13, vent valve 16 and chamber tower spring 17 in the inner cavity formed by the joint and the hose joint , forming a sealed whole. On the inner wall of the circular hole of the connector 11, a circle of concave engaging grooves 113 is formed.

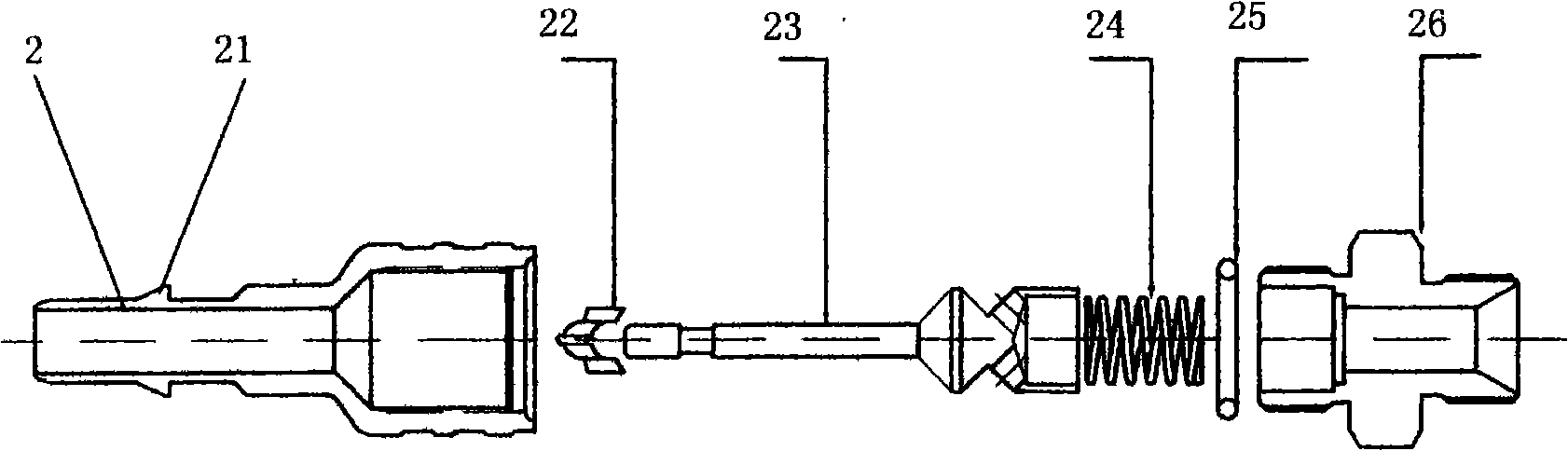

[0029] exist figure 2 Among them, the outer wall of the front end of the valve jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com