Tilt rotor vector propulsion device used in underwater propeller

A vector propulsion, tilt-rotor technology, applied in underwater ships, underwater operation equipment, transportation and packaging, etc., can solve the problems of accelerated water flow, low efficiency, low action sensitivity, etc. The effect of low maintenance cost and clever layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

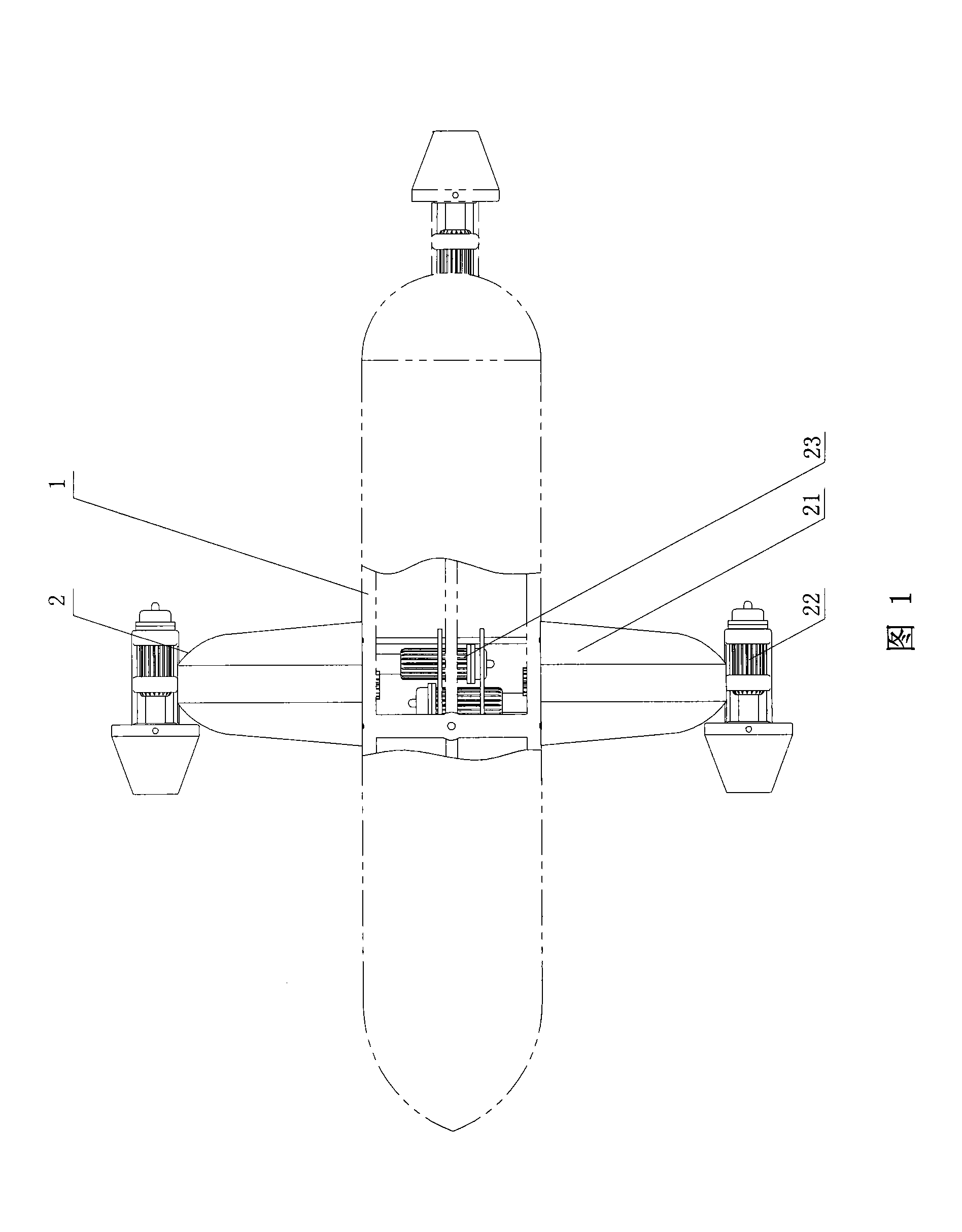

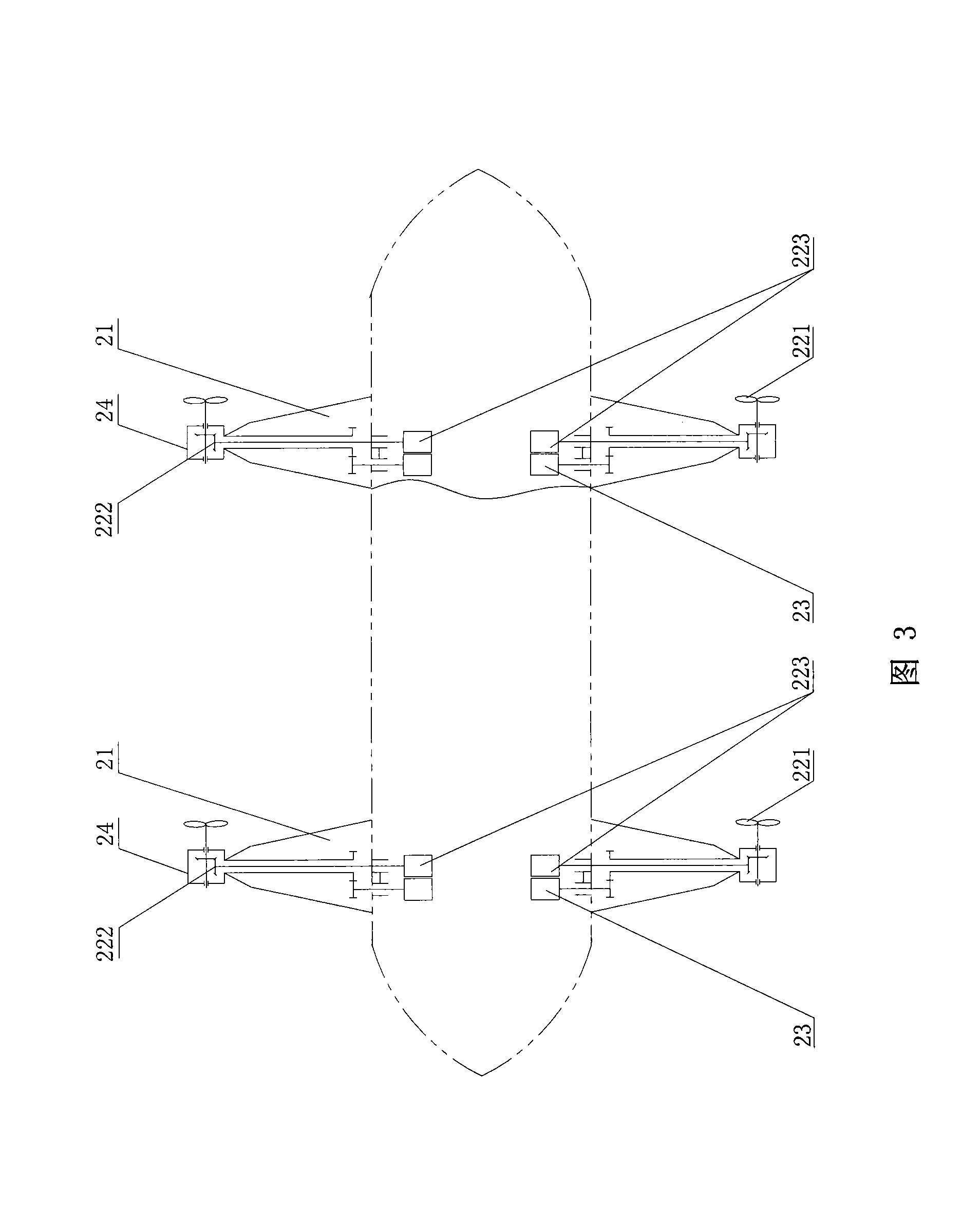

[0018] Such as figure 1 and figure 2 As shown, the tilt rotor vector propulsion device for underwater propulsion of the present invention includes a hang glider 21, a propulsion mechanism 22, a tilt drive motor 23 and a tilt frame 24, and one end of the hang glider 21 is fixed on the fuselage frame 1 Above, the tilting frame 24 is supported on the other end of the hang glider 21 through a bearing, and the output end of the tilting drive motor 23 is connected with the tilting frame 24 through a gear pair. This propulsion mechanism 22 comprises flank propeller 221, flank propeller transmission mechanism 222 and flank propeller driving motor 223, and flank propeller 221 is supported on the tilting frame 24 by bearing, and the output end of flank propeller driving motor 223 connects with flank through flank propeller transmission mechanism 222. The rotating shafts of the propellers 221 are connected to each other. Driven by the tilting drive motor 23 , the tilting frame 24 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com