Yeast extract, preparation method and application thereof

A yeast extract, thermal reaction technology, applied in application, food preparation, food science and other directions, can solve the problems of burnt taste, unsuitable addition, adverse effects of soy sauce and sauce flavor, etc., to achieve natural and soft taste and improve quality indicators , The effect of masking bad odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

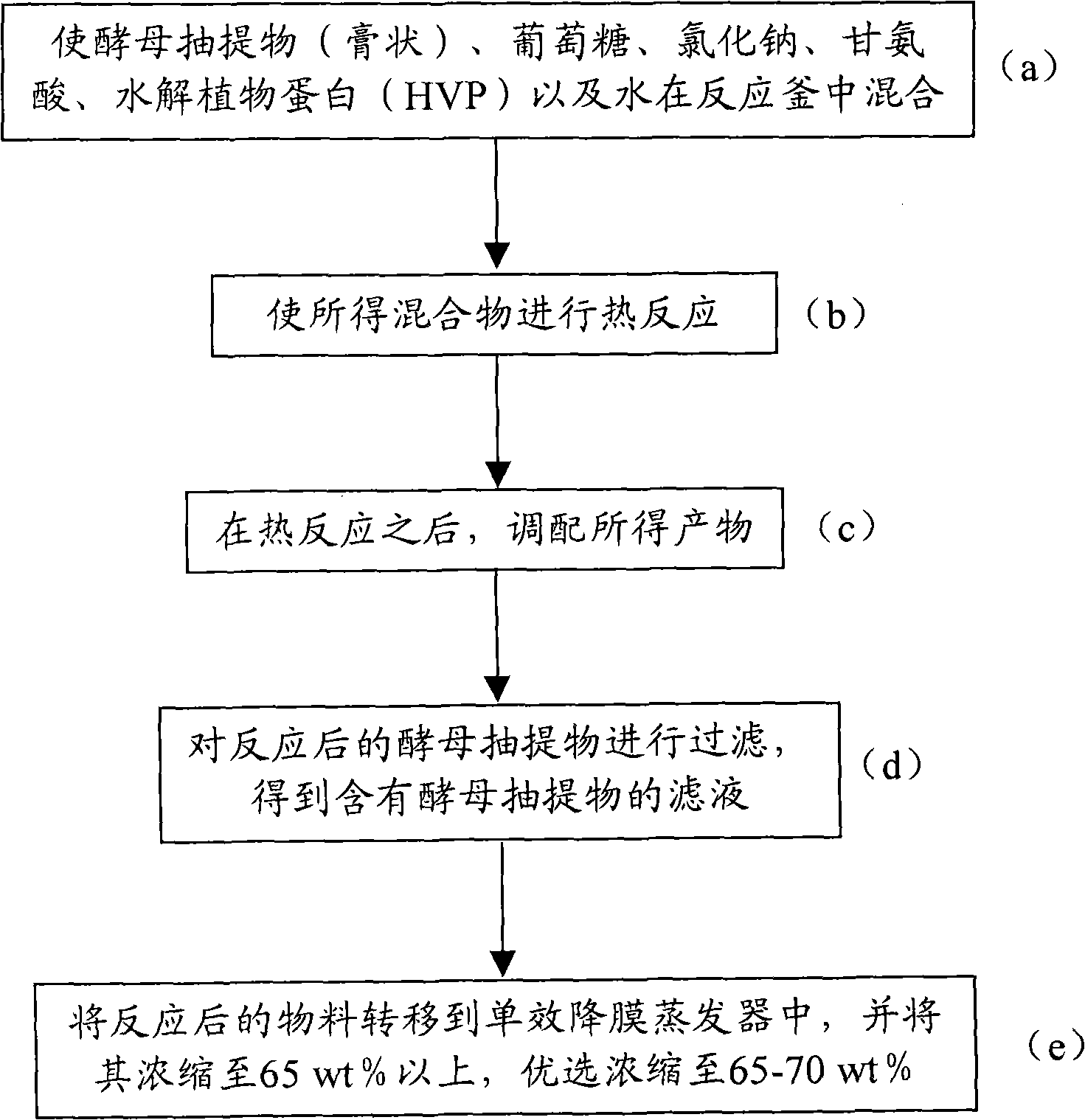

Method used

Image

Examples

preparation example Construction

[0022] According to the preparation method of yeast extract of the present invention, wherein after said step (d), step (e) may also be included: transferring the filtrate containing yeast extract to a single-effect falling film evaporator, and It is concentrated to above 65 wt%, preferably to 65-70 wt%.

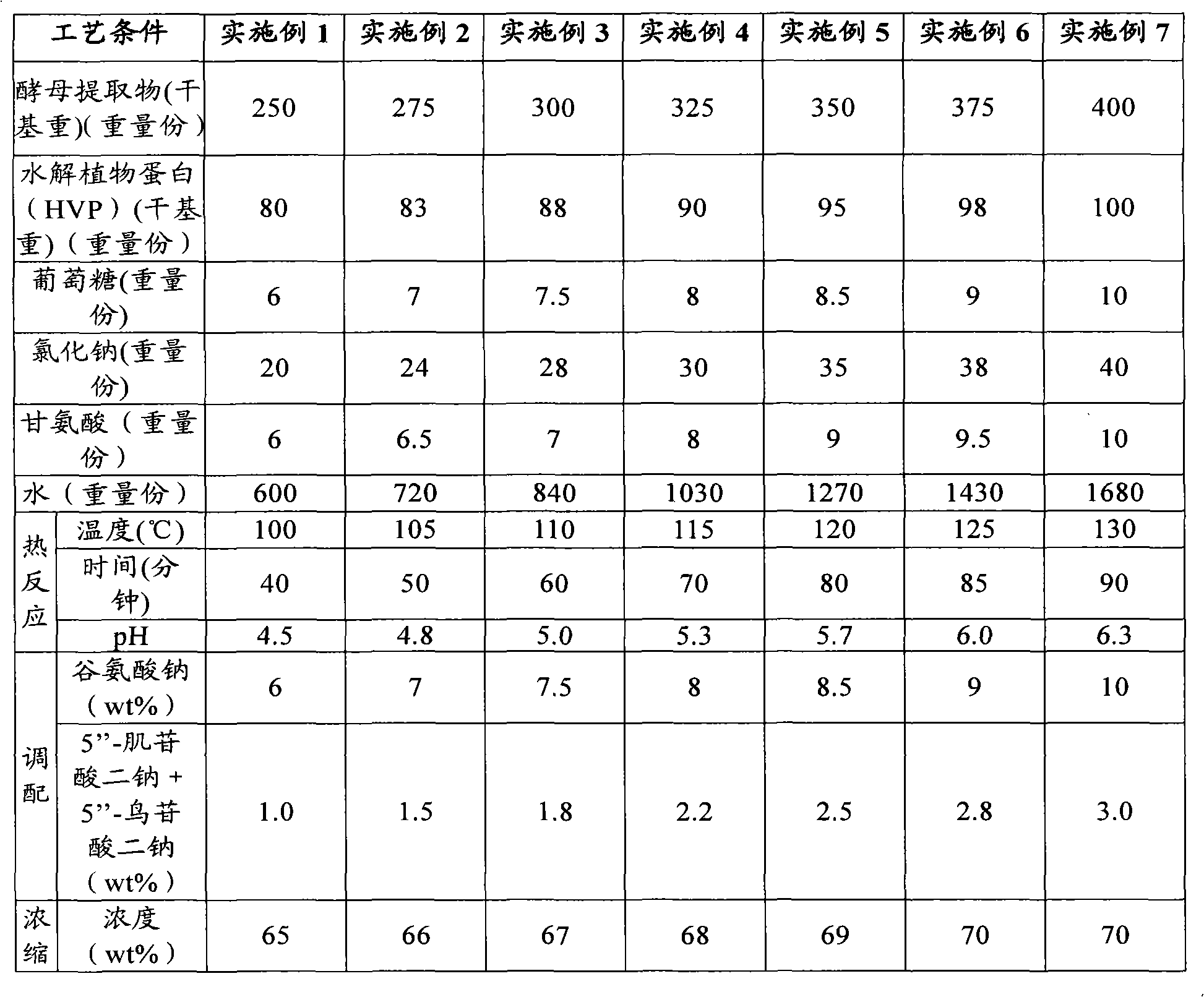

[0023] In a specific embodiment of the present invention, the raw material composition in step (a) is: 250-400 parts by weight (dry basis) of yeast extract (paste), 6-10 parts by weight of glucose, 20-40 parts by weight Parts by weight of sodium chloride, 6-10 parts by weight of glycine, 80-100 parts by weight (dry basis) of hydrolyzed vegetable protein and an appropriate amount of water to make the concentration of the reactant 25-40%.

[0024] In a specific embodiment of the present invention, in step (b), the mixture obtained in step (a) is kept at 100-130°C, preferably 100-120°C, and more preferably 110-120°C, at a pH of 4.5- 6.3, preferably 5.0-6.0 heat reaction for 40...

Embodiment 1

[0035] Embodiment 1 At first, make the yeast extract (paste) of 250 parts by weight (dry basis), the glucose of 6 parts by weight, the sodium chloride of 20 parts by weight, the glycine of 6 parts by weight, the glycine of 80 parts by weight (dry basis The hydrolyzed vegetable protein of meter) and the water of 600 parts by weight are mixed in a reaction kettle. Then, the resulting mixture was transferred to a reaction kettle, and then the mixture was thermally reacted at 100° C. and pH 4.5 for 40 minutes. After heating and precipitating, add 6wt% sodium glutamate and 1.0wt% "5"-disodium inosinate+5"-disodium guanylate" for blending. In order to prevent the precipitation in the raw material from being brought into the final product, it is necessary to filter the yeast extract after the reaction with a 200-mesh filter cloth. After filtration, the filtrate is transferred to a single-effect falling film evaporator and concentrated to a concentration above 65 wt%, preferably to 6...

Embodiment 8-11

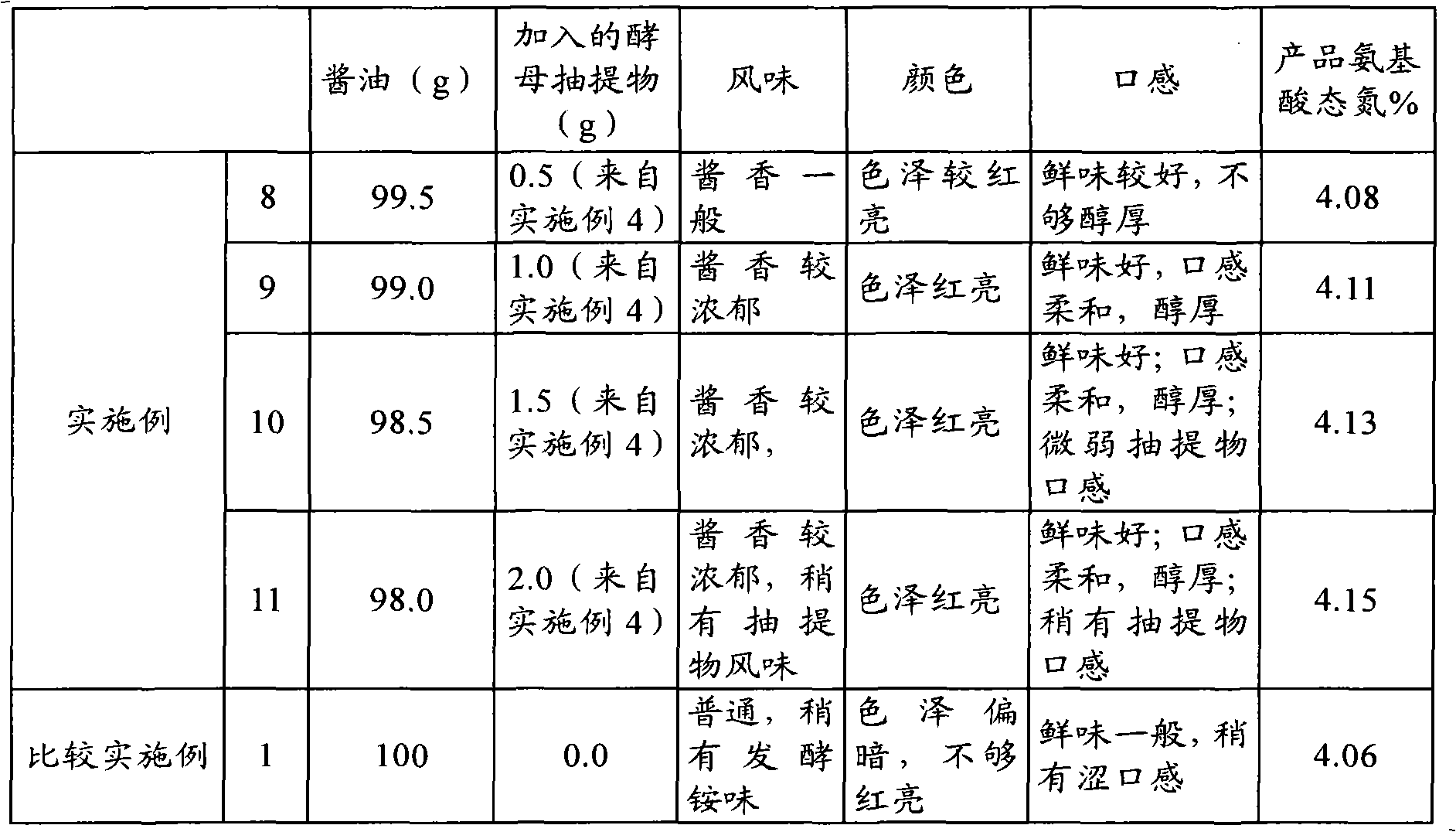

[0041] Example 8-11 Application of the yeast extract prepared according to the method of the present invention in soy sauce

[0042] The product prepared by the invention is added to the light soy sauce fermented by Yichang Yimeitang in a certain weight ratio. In Examples 8-11 shown in Table 2, the yeast extracts obtained in Example 4 were tested in amounts of 0.5%, 1.0%, 1.5% and 2.0% by weight, and the results showed that when When the addition amount is 1.0% by weight, it can effectively cover the peculiar smell of fermentation, highlight the sauce aroma of the product, ease the straight feeling of soy sauce, and make the taste softer and mellow. The test results using other ratios of the added amount of the yeast extract are shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com