Methods for carbonate pretreatment and pulping of cellulosic material

A cellulose pulp and carbonate technology, which is applied in the fields of cellulose raw material pulping, pulping with inorganic alkali, multi-stage pulping process, etc., can solve the problems of non-implementation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

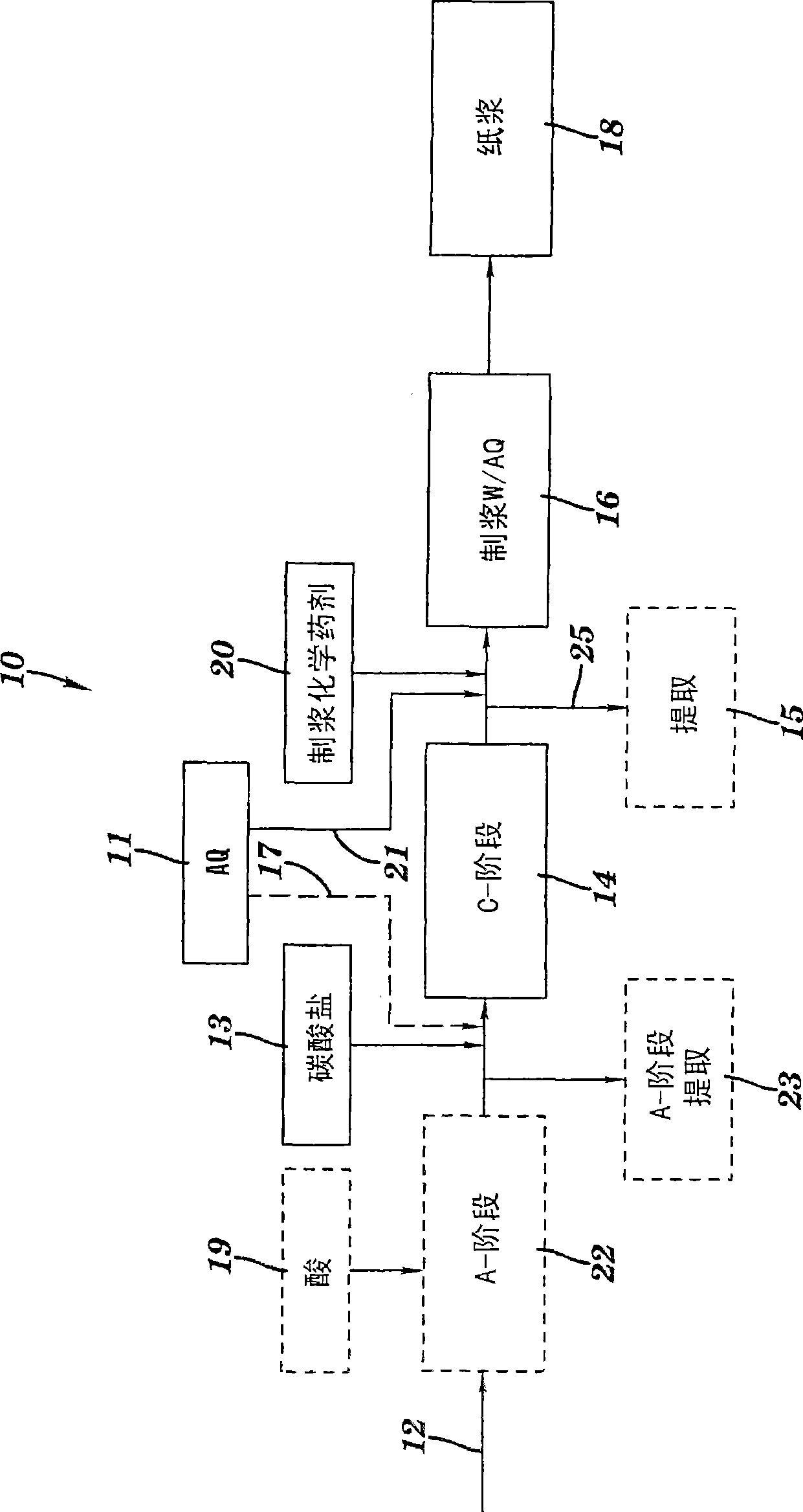

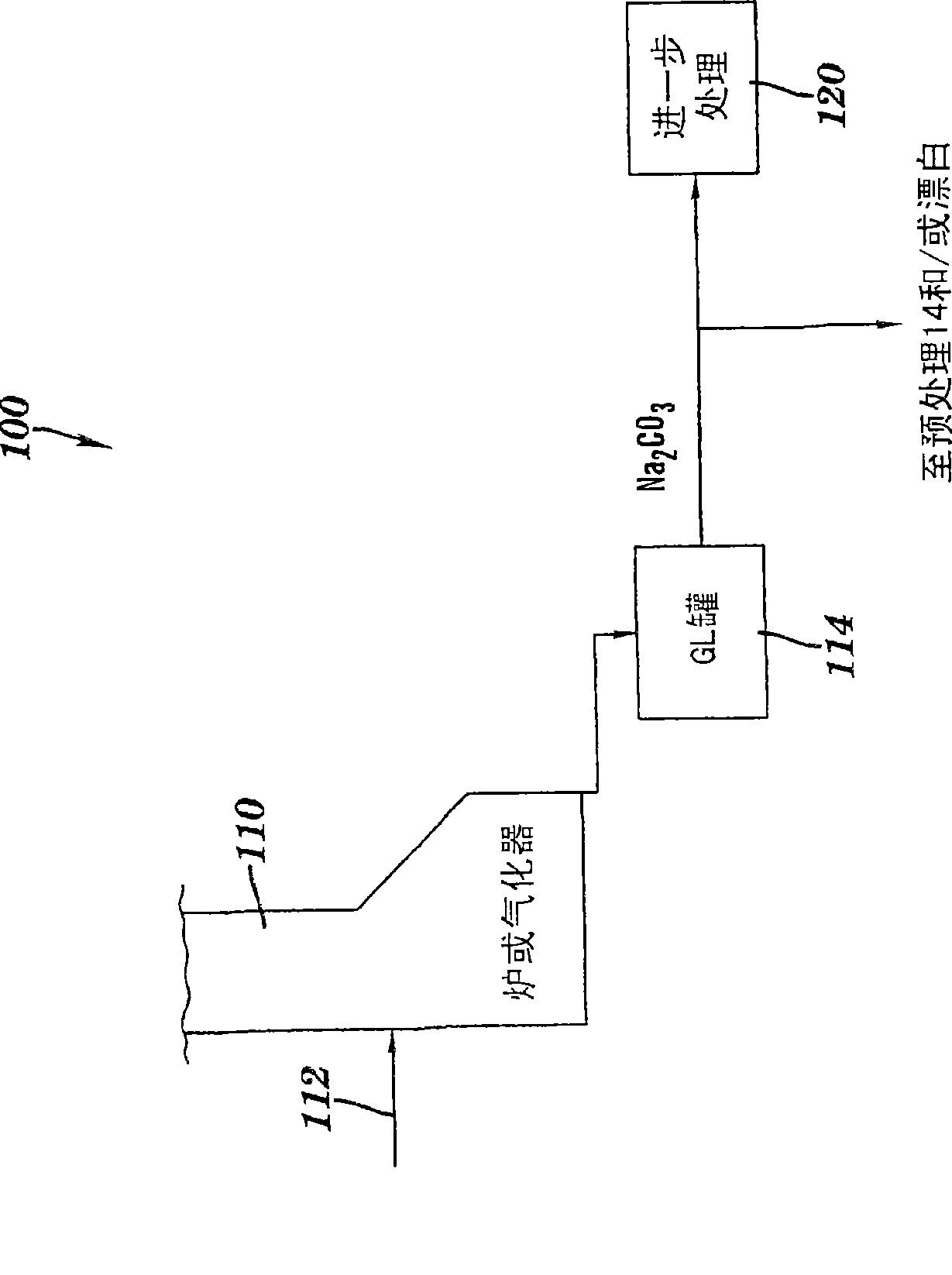

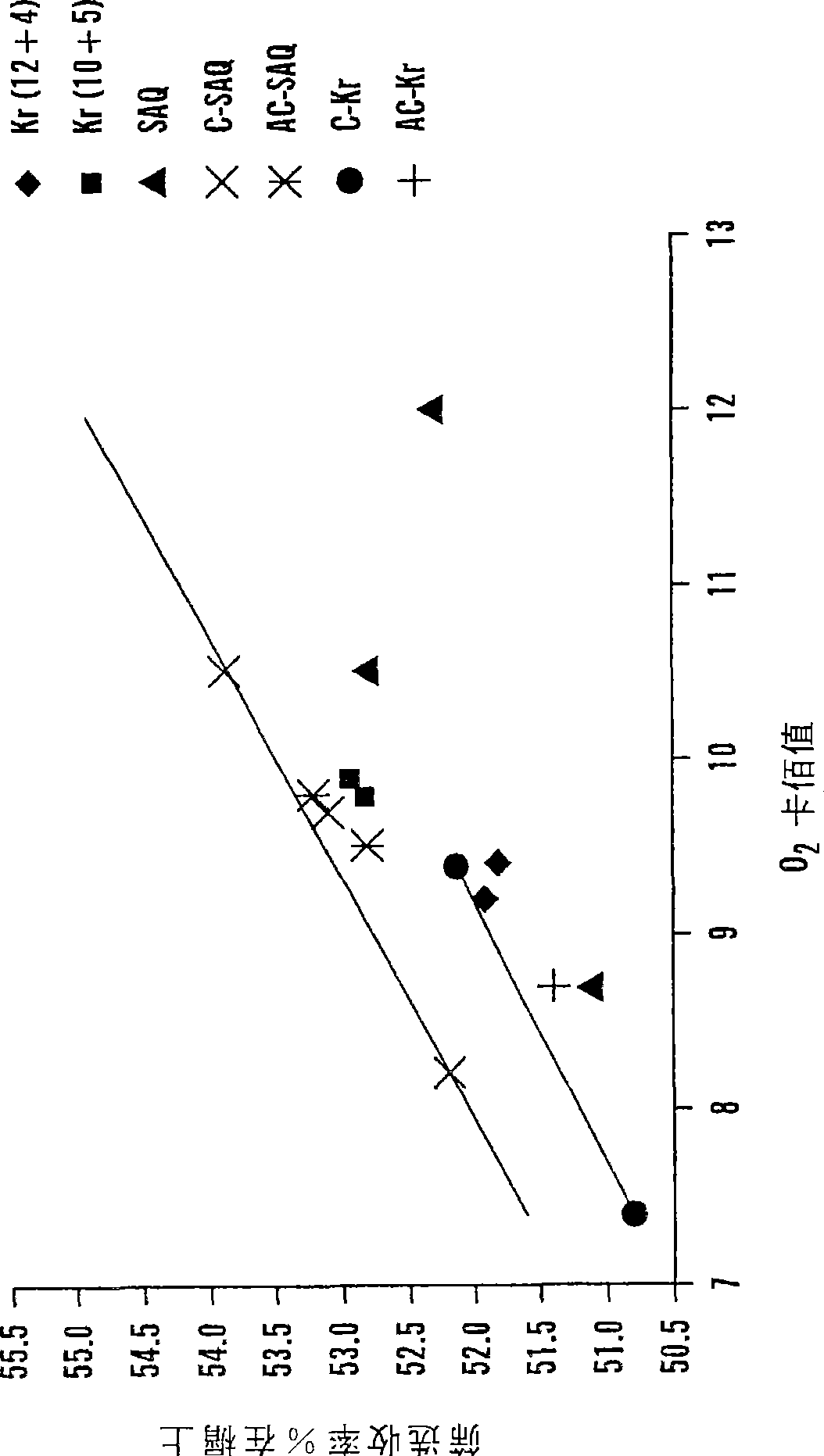

[0027] Applicants have found that by treating comminuted cellulosic fibrous material, such as wood chips, with a carbonate compound, such as substantially sulfur-free sodium carbonate, in a first pretreatment stage, and then in a second pulping stage, e.g. in the presence of anthraquinone (AQ stands for any anthraquinone) during soda pulping, - improved pulp can be produced. Improved pulp can also be produced if the pulp is acid treated before the first pretreatment stage, followed by kraft pulping in the presence of anthraquinone. For example, the pulp produced can be characterized by increased pulp yield, increased bleaching rate, higher strength, and lower off-grades, among other favorable properties.

[0028] In addition, treating the wood chips with a carbonate-containing solution prior to treating the chips with pulping chemicals can reduce the amount of pulping chemicals required for the required treatments in the pulping process. This development could have a signific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com