Polyester resin composition, process for production thereof, and laminated polyester film

A technology of polyester resin and manufacturing method, which is applied in the field of polyester resin composition, can solve problems such as inability to deal with thermal deterioration of polyester resin, scattering of diol components, inability to react with diol, etc., and achieve excellent thermal stability and low refractive index and photoelastic coefficient are low, and the effect of inhibiting gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

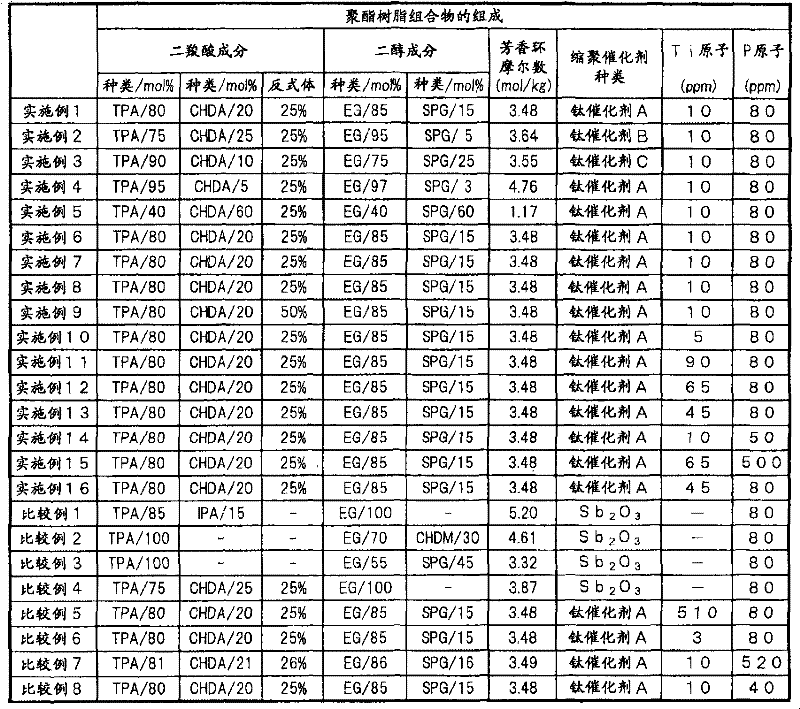

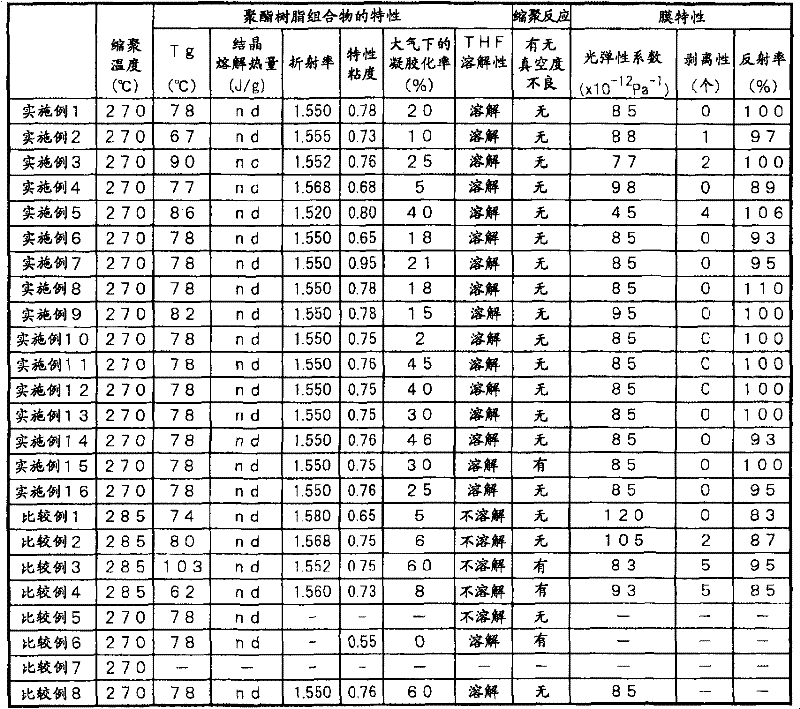

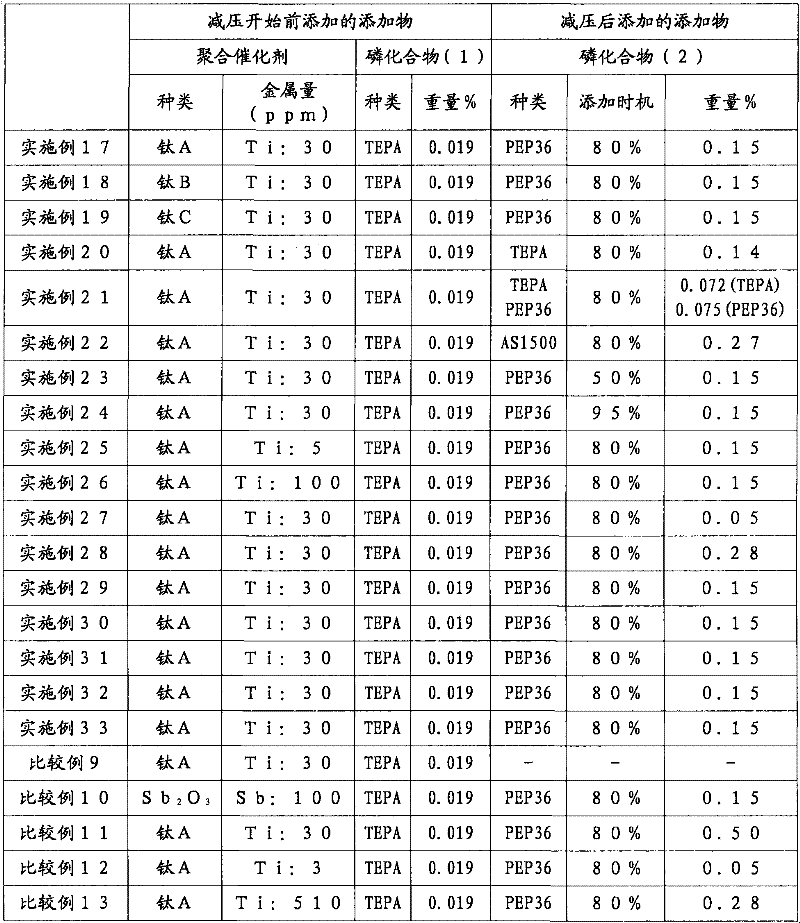

[0105] Hereinafter, examples are given to further specifically describe the present invention. In addition, the measuring method of a physical property and the evaluation method of an effect were performed by the following method.

[0106] (1) Thermal properties of polyester (glass transition temperature, heat of crystal fusion)

[0107] About 10 mg of the sample to be measured was weighed, sealed with an aluminum pan and a pan lid, and measured with a differential scanning calorimeter (model DSC7 manufactured by Perkin Elmer Co., Ltd.). In the measurement, the temperature was raised from 20°C to 285°C at a rate of 16°C / min in a nitrogen atmosphere, then rapidly cooled with liquid nitrogen, and the temperature was raised again from 20°C to 285°C at a rate of 16°C / min in a nitrogen atmosphere . The glass transition temperature was measured during this second temperature rise.

[0108] In addition, the heat of crystal fusion was calculated from the area of the crystal melti...

reference example 1

[0150] Reference example 1 (the synthetic method of titanium catalyst A. citric acid chelated titanium compound)

[0151] Into a 3 L flask equipped with a stirrer, a condenser and a thermometer, warm water (371 g) and citric acid monohydrate (532 g, 2.52 mol) were added, dissolved and stirred. To this stirred solution, titanium tetraisopropoxide (284 g, 1.0 mol) was slowly added dropwise from the dropping funnel. The mixture was heated and refluxed for 1 hour to obtain a turbid solution. The isopropanol / water mixture was distilled off from the obtained solution under reduced pressure. While cooling the remaining solution to a temperature lower than 70° C. and stirring, 380 g of a 32% by weight aqueous solution of NaOH was slowly added dropwise from the dropping funnel. The obtained product was filtered, then mixed with ethylene glycol (504 g, 8.1 mol), and heated under vacuum to remove isopropanol / water to obtain a slightly turbid pale yellow product (Ti content 3.85% by wei...

reference example 2

[0152] Reference example 2 (the synthetic method of titanium catalyst B. lactic acid chelated titanium compound)

[0153] Titanium tetraisopropoxide (284 g, 1.0 mol) was placed in a 2 L flask equipped with a stirrer, a condenser, and a thermometer, and ethylene glycol (218 g, 3.51 mol) was added from the dropping funnel while stirring. The rate of addition was adjusted as the heat of reaction warmed the contents of the flask to about 50°C. The obtained reaction mixture was stirred for 15 minutes, and then 252 g of an 85% by weight aqueous solution of ammonium lactate was added to obtain a transparent pale yellow product (Ti content: 6.54% by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com