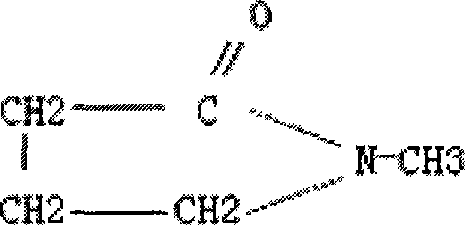

Purification method of N-methyl pyrrolidone

The technology of a methyl pyrrolidone and a purification method is applied in the production field of heterocyclic compounds, and can solve the problems of low purity and yield of N-methyl pyrrolidone, and achieve the effects of strong selectivity, strong solubility and high boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is to add the sodium salt of strong base and weak acid of water blocking agent into the crude product liquid according to 0.1-2% of the crude product liquid, and then pour it into the rectification system of the three-tower combination of the deamination tower, the dehydration tower and the product tower in sequence. Packing, three-tower continuous vacuum rectification, the pressure is controlled at -80 to -95kPa, the advanced rectification operation method is adopted based on the principle of optimal reflux separation effect, and the reflux ratio of 1.5-3 is used to extract the product, effectively controlling the The content of impurities such as metal ions improves the yield and purity of the product; the content of impurities such as metal ions is effectively controlled, the product purity is ≥99.9%, the water content is ≤100ppm, and the yield of N-methylpyrrolidone is over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com