Transverse and longitudinal distance and angle adjustable universal oil tube apparatus of oiling machine

A technology with adjustable longitudinal distance, which is applied in distribution devices, transportation and packaging, special distribution devices, etc. It can solve the problems of difficult adjustment of size and angle, difficulty in ensuring connection effect, difficulty in connecting pipes, etc., to achieve long-term stability seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

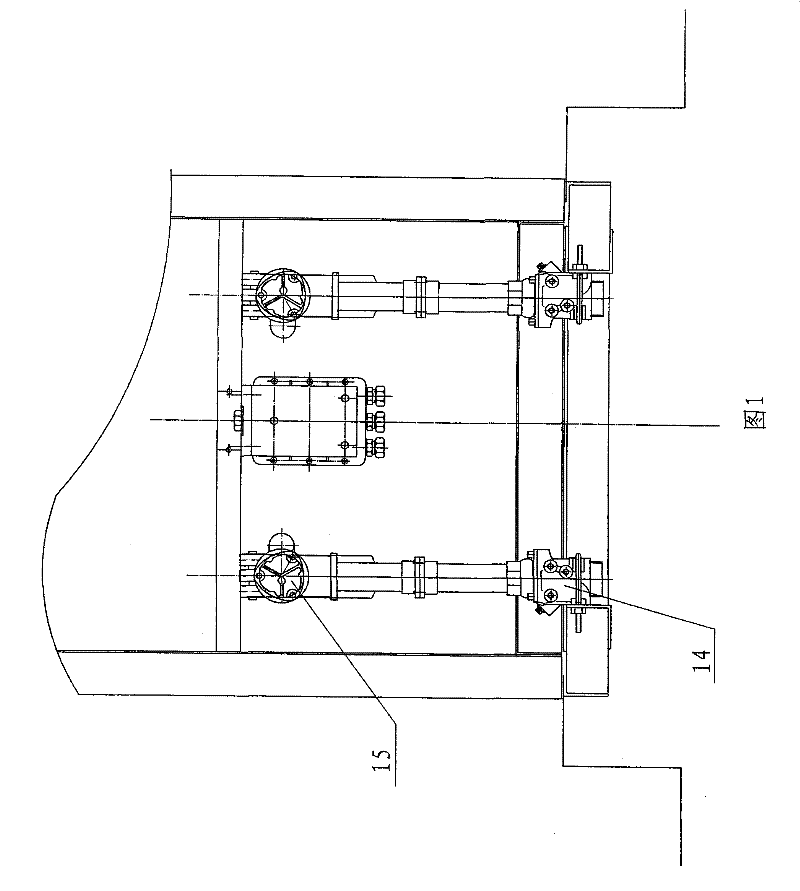

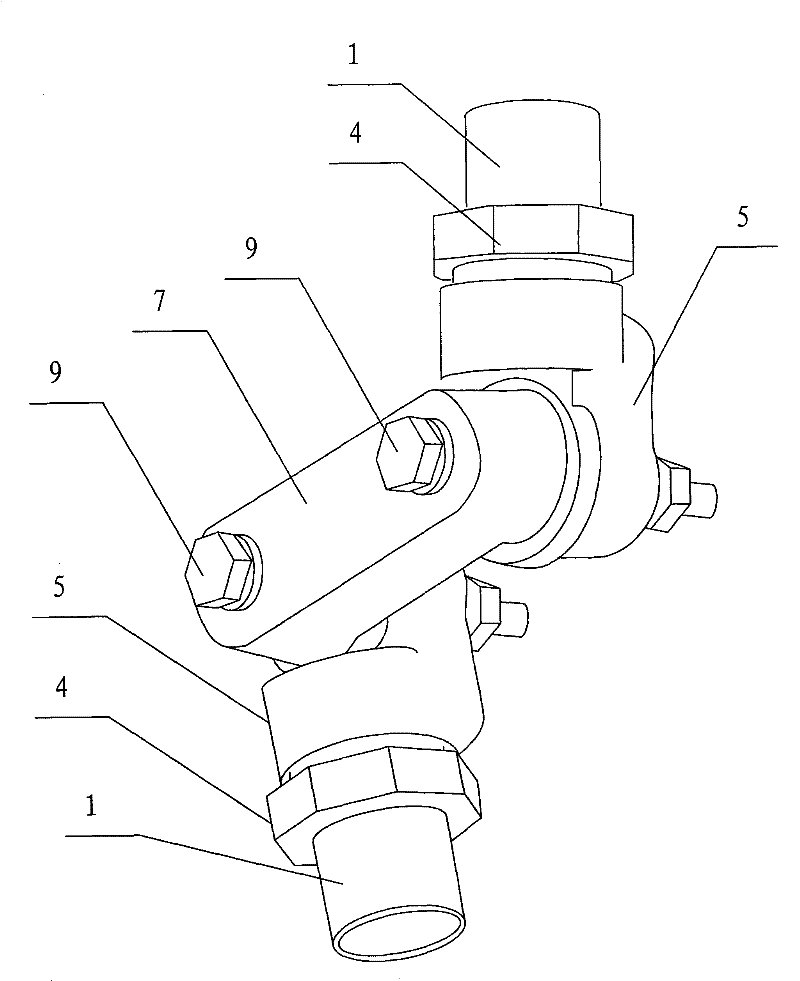

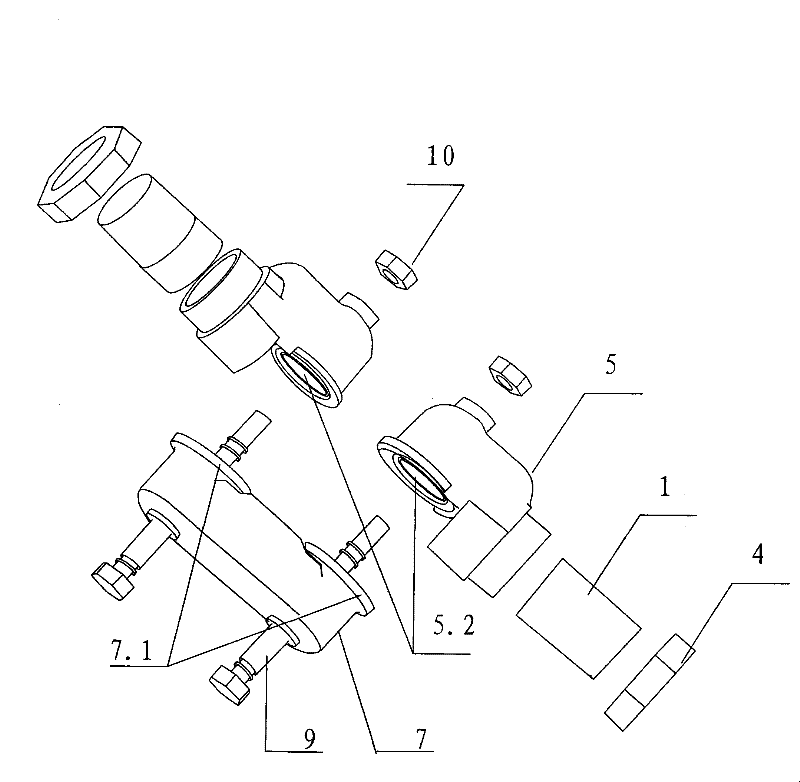

[0021] see Figure 2-6 , the present invention relates to the adjustable horizontal and vertical distances and angles of the tanker universal oil inlet pipe device, mainly composed of a connecting pipe 1, a pressure sleeve 2, an O-ring I 3, a lock nut 4, a pipe body 5, and an O-ring II 6. Tube seat 7, O-ring III8, long bolt 9, nut 10, spring washer 11 and flat washer 12. Described connecting pipe 1 and pipe body 5 all have two pieces, each one up and down, and one end of described two pieces connecting pipe 1 up and down is shaped on external thread 1.1, is used for being respectively connected with the input nozzle of fuel dispenser and the oil inlet pipe thread. The other end of the upper and lower two connecting pipes 1 is a light pipe, and one end of the upper and lower two pipe bodies 5 is formed with an external thread 5.1, and the light pipe end of the connecting pipe 1 is inserted into the external thread 5.1 of the pipe body 5. One end of the lock nut 4 has two piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com