Boring machine of negative-pressure conduction lapping material

A technology of wrapping material and negative pressure drainage, applied in suction equipment, metal processing, etc., can solve the problems of high labor intensity, easy generation of debris, low efficiency, etc., and achieve the effect of improving product quality, improving work efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

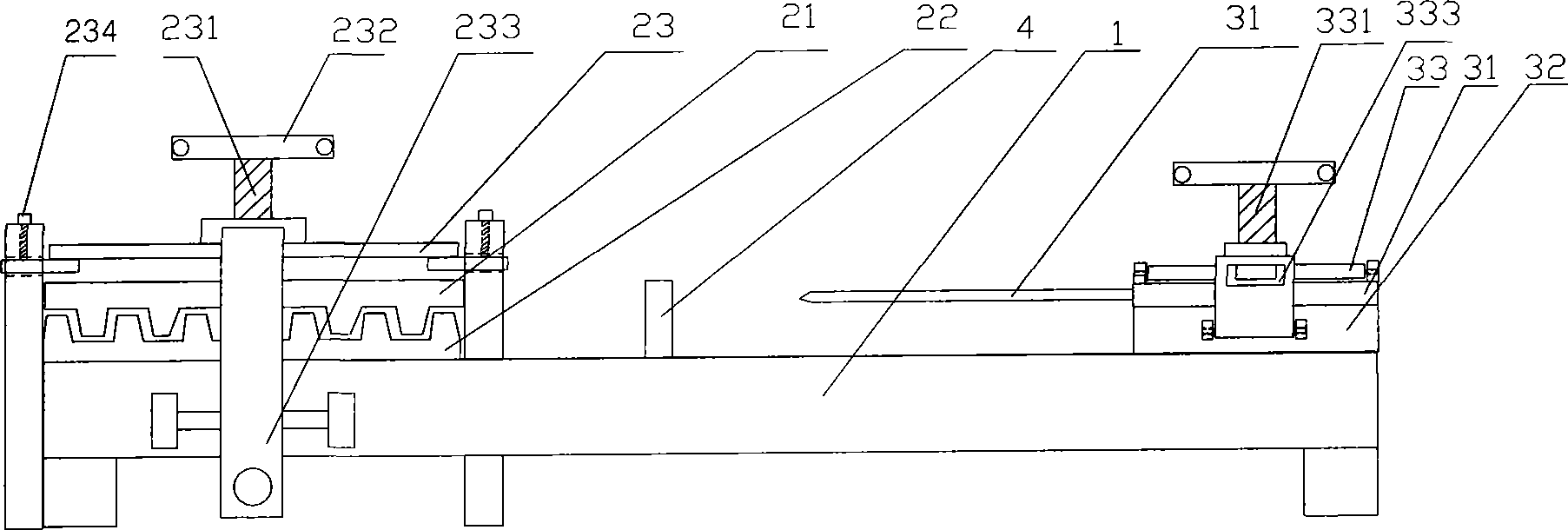

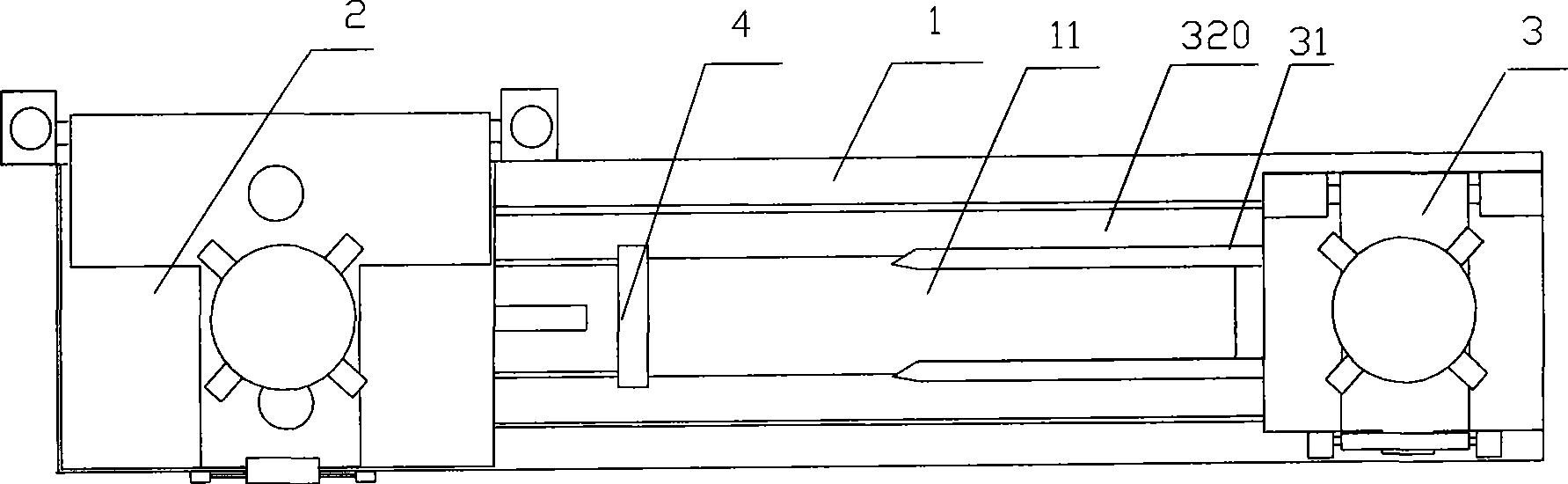

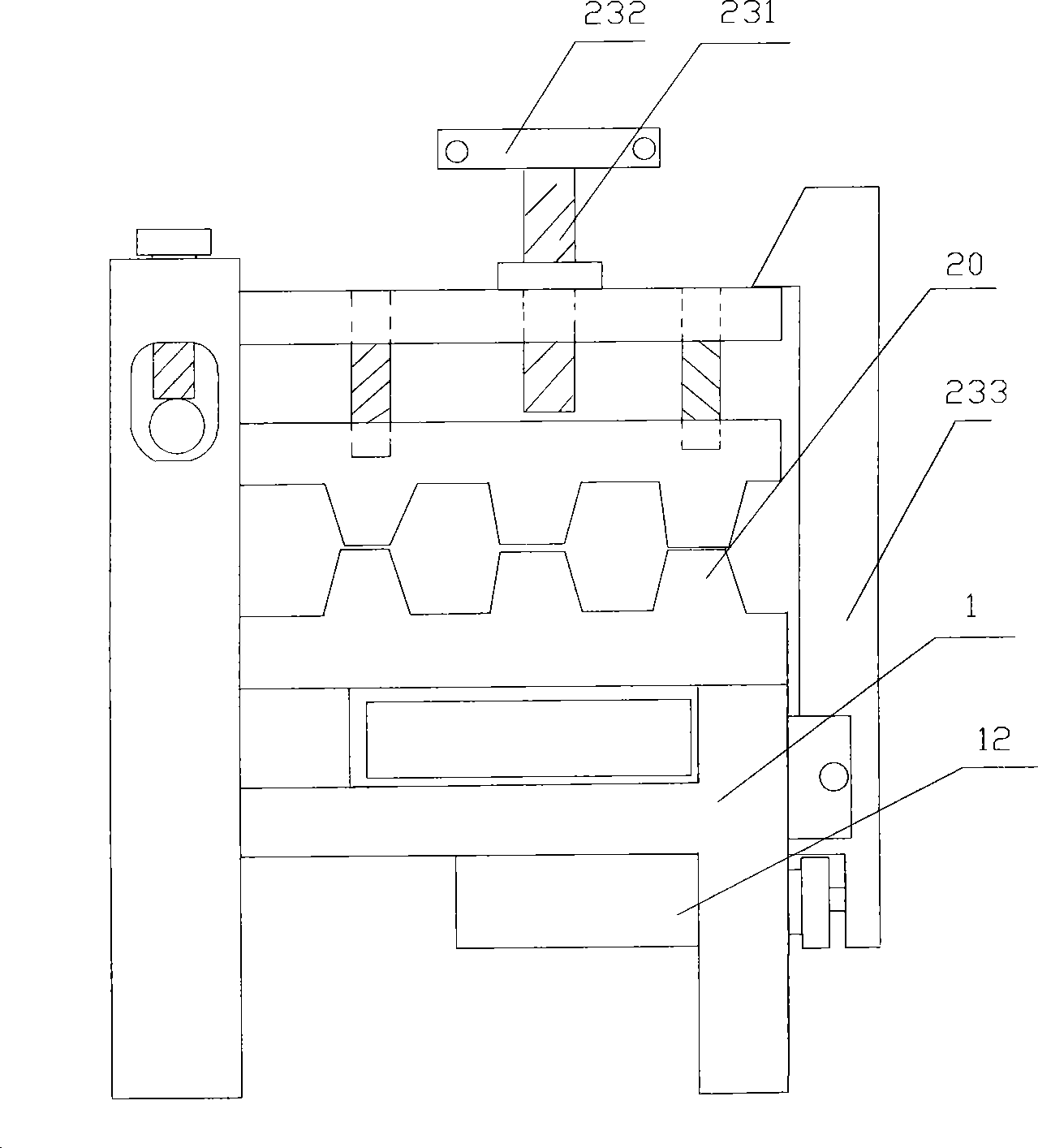

[0020] Referring to the accompanying drawings, it can be seen that the negative pressure drainage wrapping material punching machine of the present invention includes a base 1, a chute 11 is arranged in the middle of the base 1, a wrapping material pressing device 2 is arranged at one end of the base 1, and a wrapping material pressing device 2 is arranged at the other end of the base 1. There is a punching device 3 that can slide along the chute 11, and the punching needle 31 on the punching device 3 can pass through the wrapping material in the pressing device 2 (such as figure 1 , figure 2 shown).

[0021] The pressing device 2 includes an upper pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com