Flexible bus bar connector

A wire connector, metal technology, applied in the direction of connection, connecting device parts, electrical components, etc., can solve the problems such as the height of the electrical connector cannot be lowered, the strength is not enough, and the looseness, etc., to achieve smooth and stable electrical transmission. The effect of increasing rigidity and strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

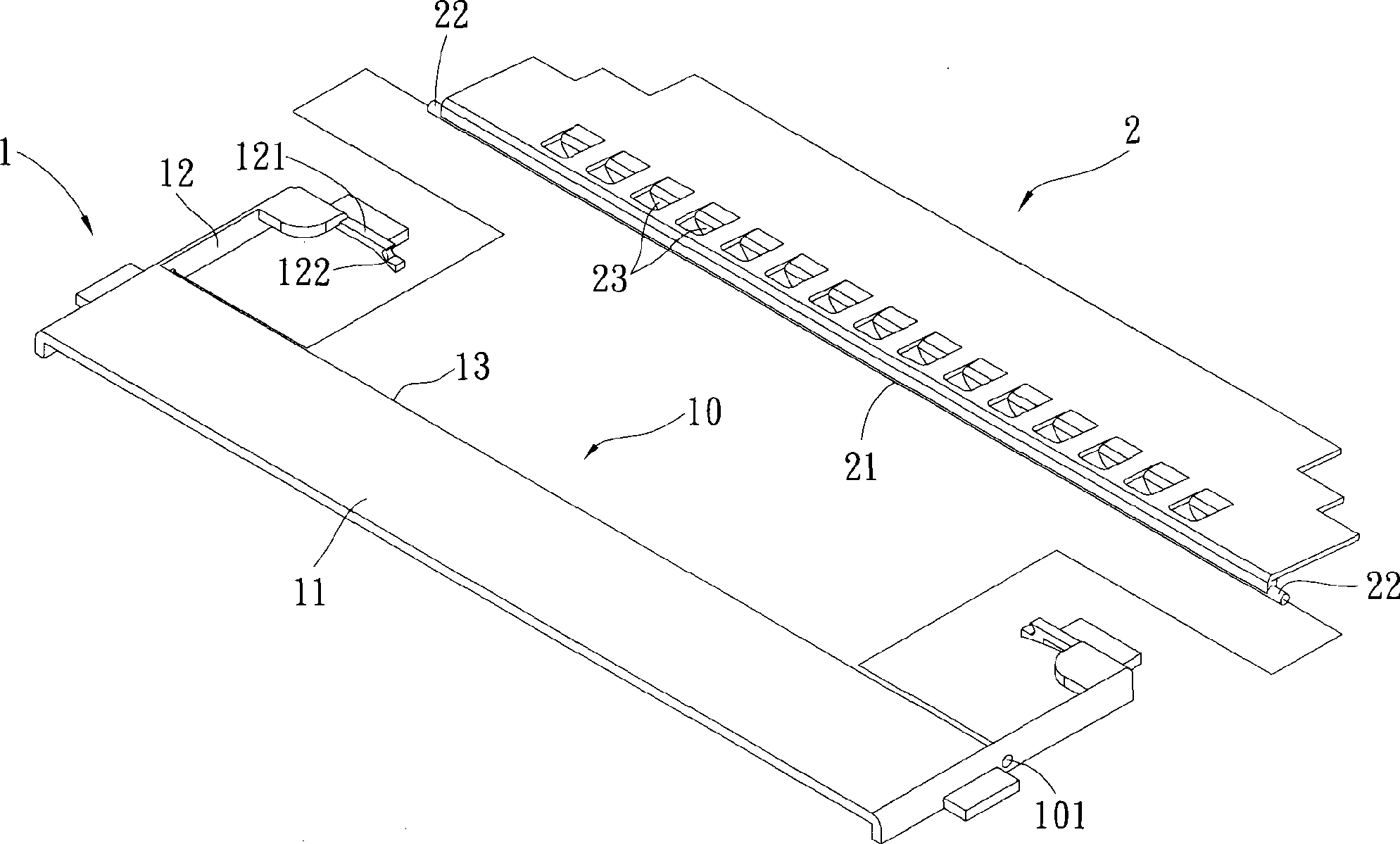

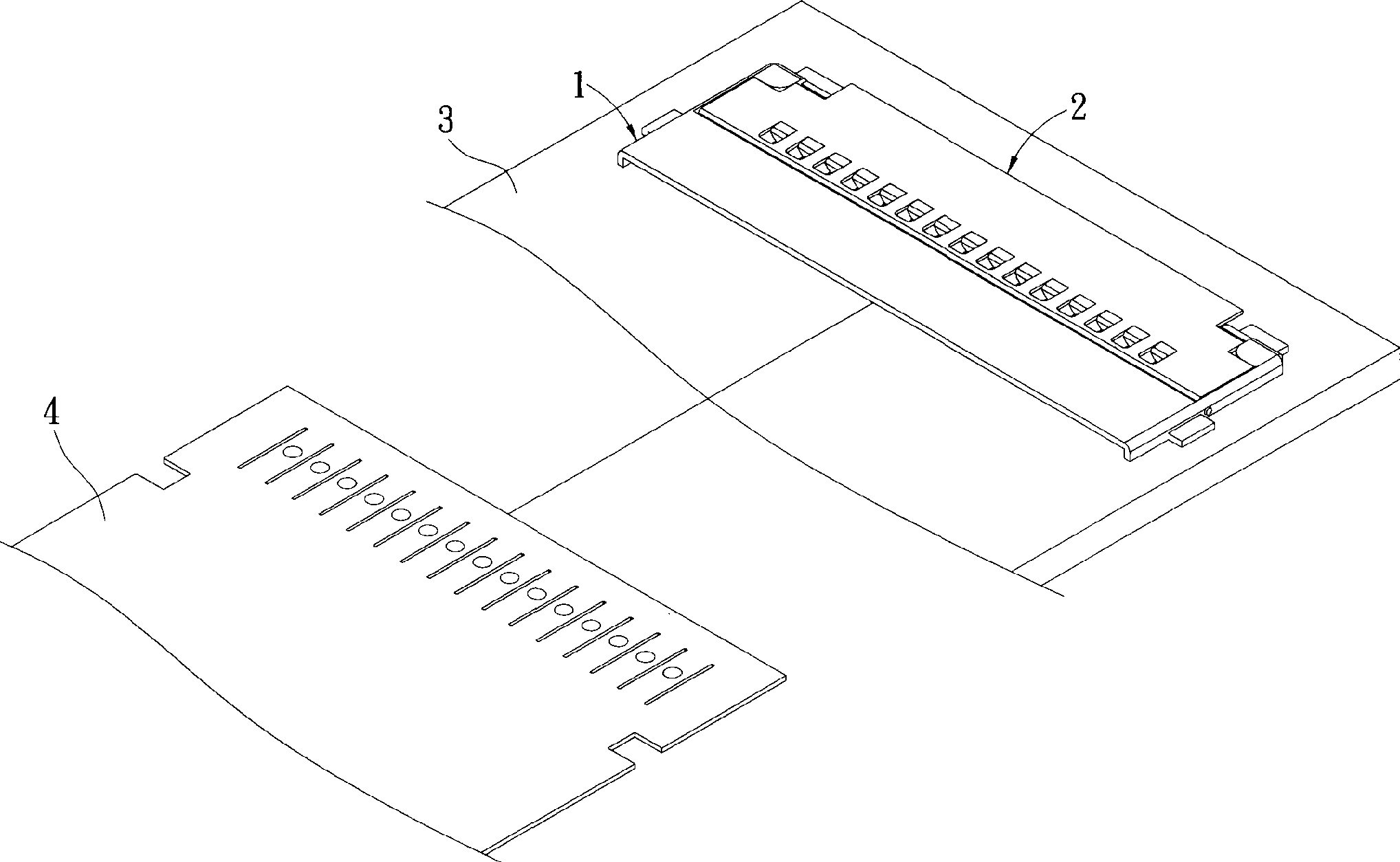

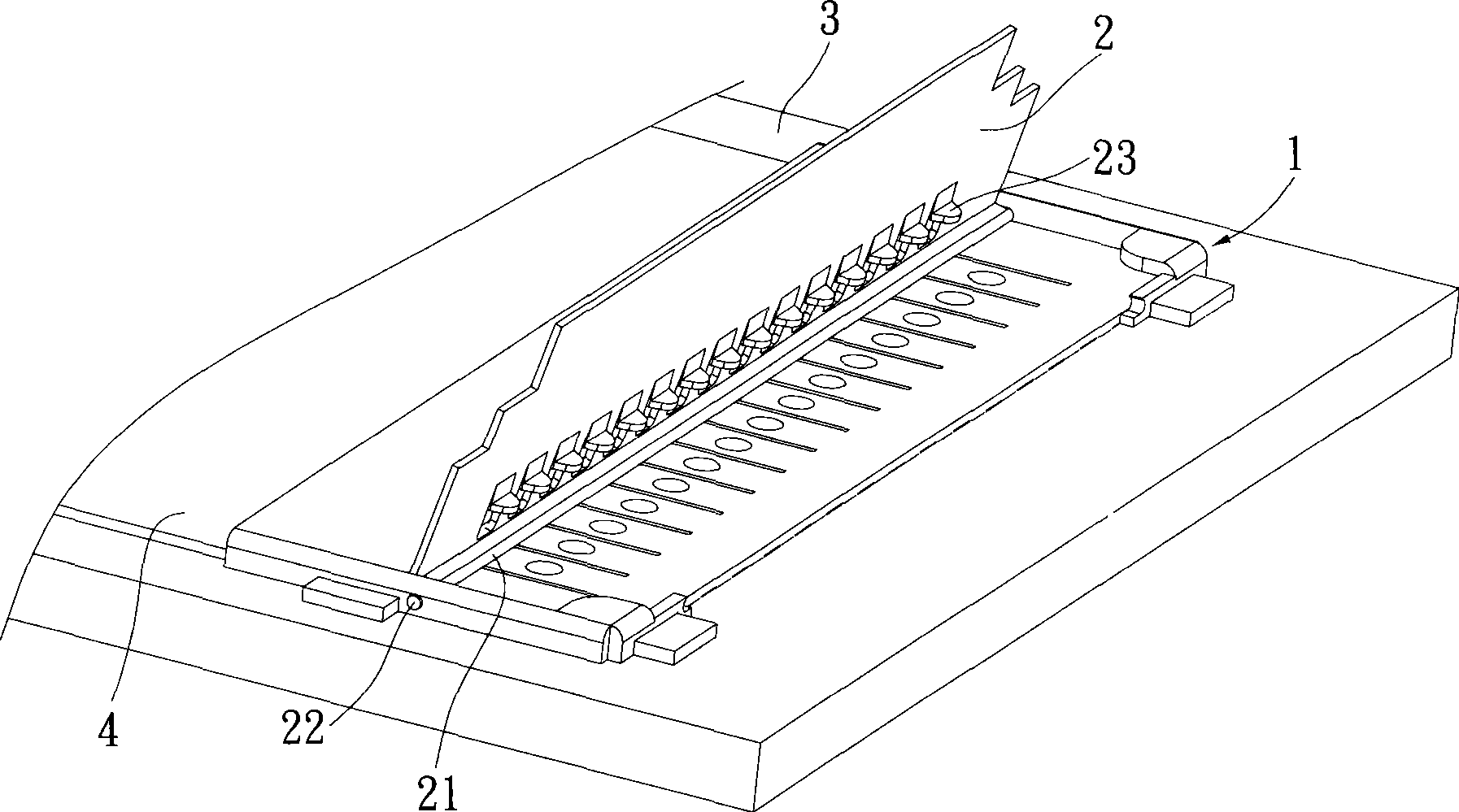

[0026] see Figure 1 to Figure 5 As shown, it is a diagram illustrating the specific implementation of the flexible cable connector of the present invention, please cooperate with the diagram for the following description. The flexible cable connector is composed of a thin base 1 and a metal flip cover 2; the thin base 1 can be used to be arranged on the top of the circuit board 3 for the insertion of the flexible cable 4, The structure and characteristics of each component will be described below firstly. In the embodiment of the present invention, the direction in which the flexible cable 4 is inserted is defined as the front:

[0027] The thin base 1 has a flat upper wall 11, and corresponding side walls 12 extending backward from both sides of the upper wall 11, so that the upper wall 11 and the two side walls 12 together form a receiving space 10, and the The rear end of the upper wall 11 is provided with an opening 13, and a corresponding shaft hole 14 is respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com