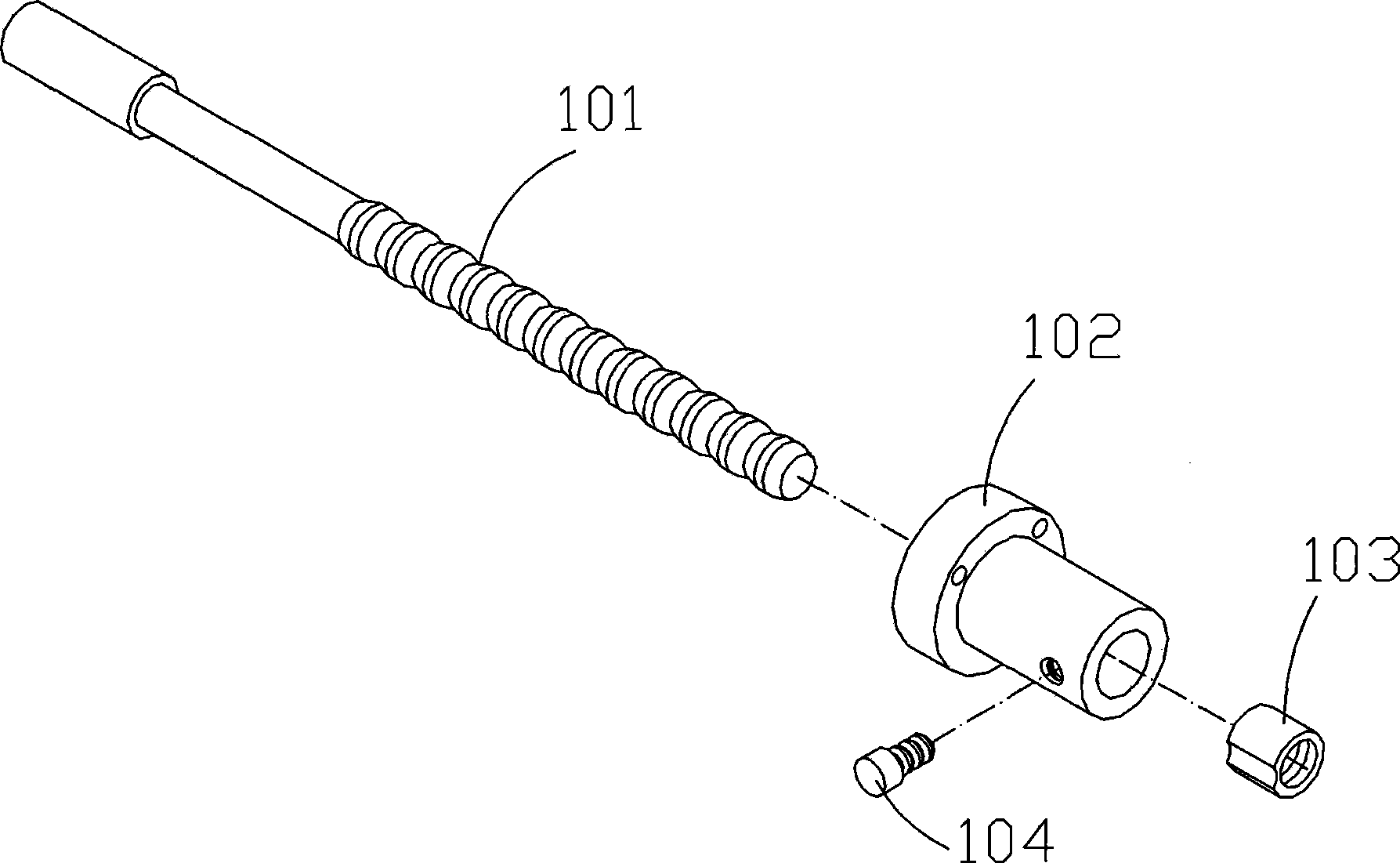

Apparatus for eliminating clearance between screw mandrel and nut

A technology of nuts and screw rods, which is applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems affecting machining accuracy and achieve the effect of improving machining accuracy and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

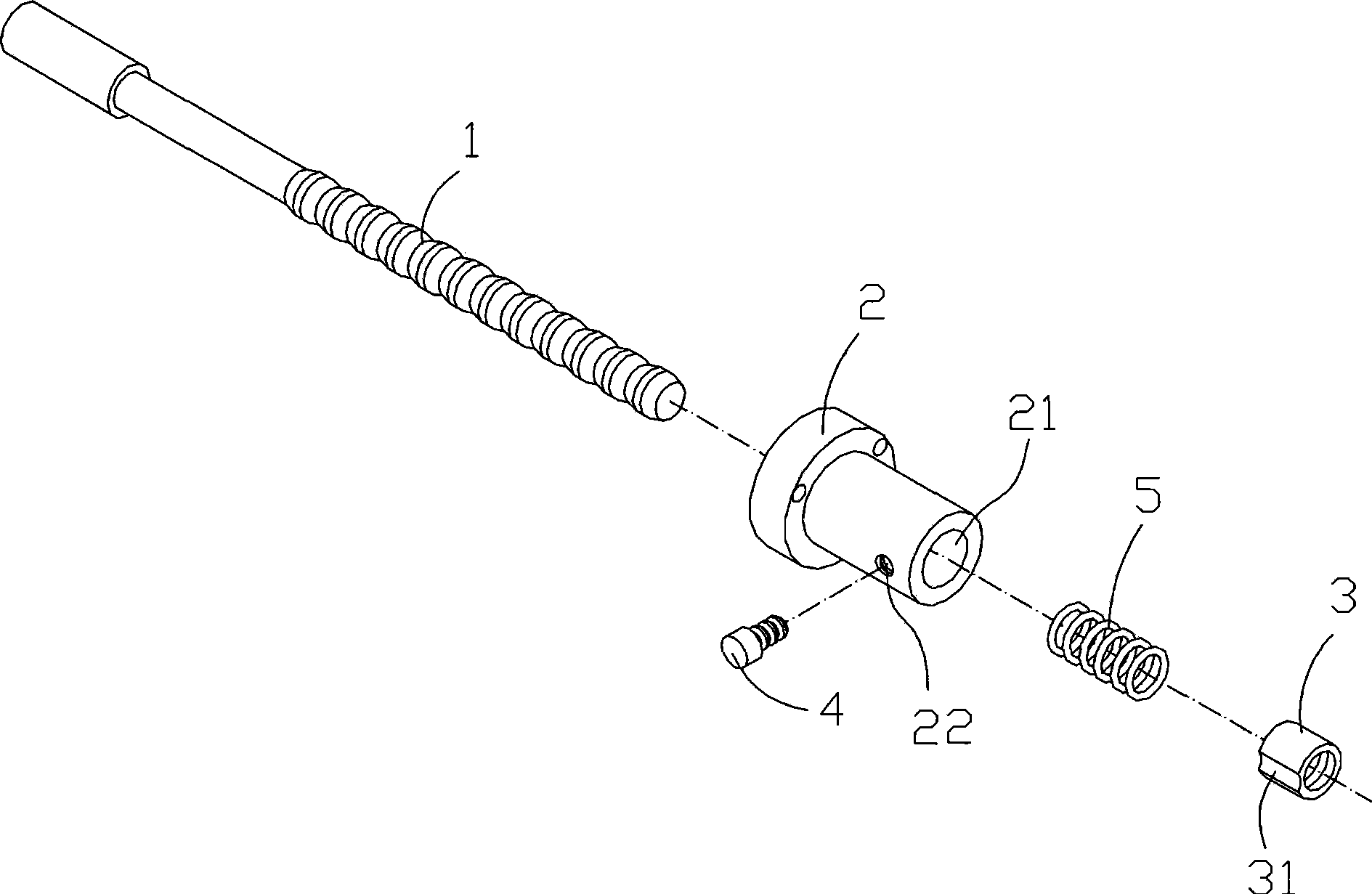

[0014] See figure 2 , 3 Shown: The gap elimination device between screw rod and nut, including screw rod 1, main nut 2, nut 3, and bolt 4, screw rod 1 is screwed in the receiving hole 21 in the main nut 2, screw rod 1 and nut 3 are screwed Together, the nut 3 is inserted into the receiving hole 22 of the main nut 2, the bolt 4 is screwed into the screw hole 22 on the main nut 2 and presses the nut 3; one end of the spring 5 acts on the nut 3, and the other end acts Force on the receiving hole 21 of the main nut 2 .

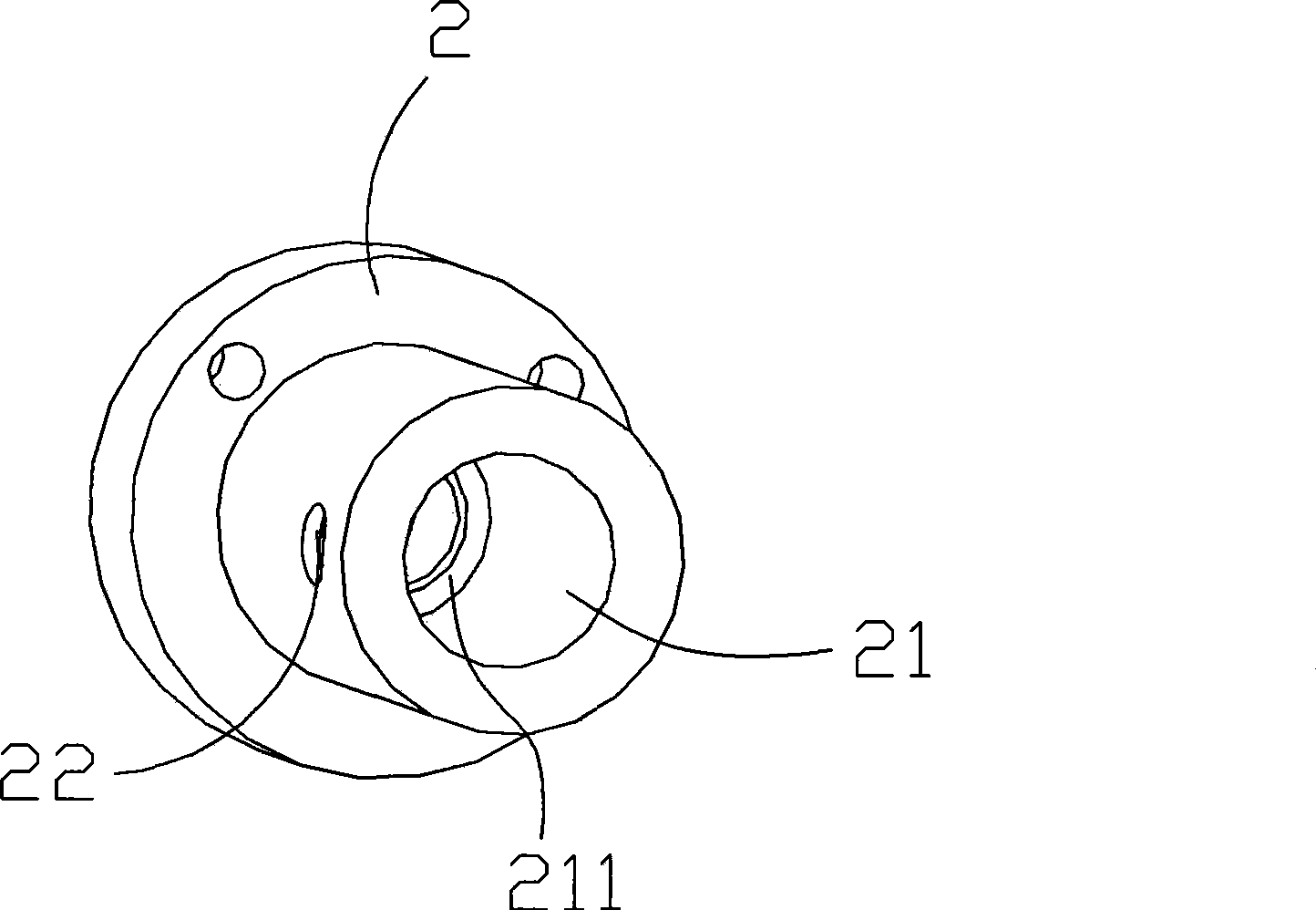

[0015] The receiving hole 21 of the main nut 2 has a step 211 , and one end of the spring 5 acts on the step 211 .

[0016] The nut 3 has a recessed surface 31 on which the bolt 4 is pressed.

[0017] Working principle: This device is equipped with a spring 5 in the main nut 2, and the elastic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com