Stabilized seal for rock bits

A technology of drill bit and sealing ring, used in construction and other directions, can solve problems such as sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

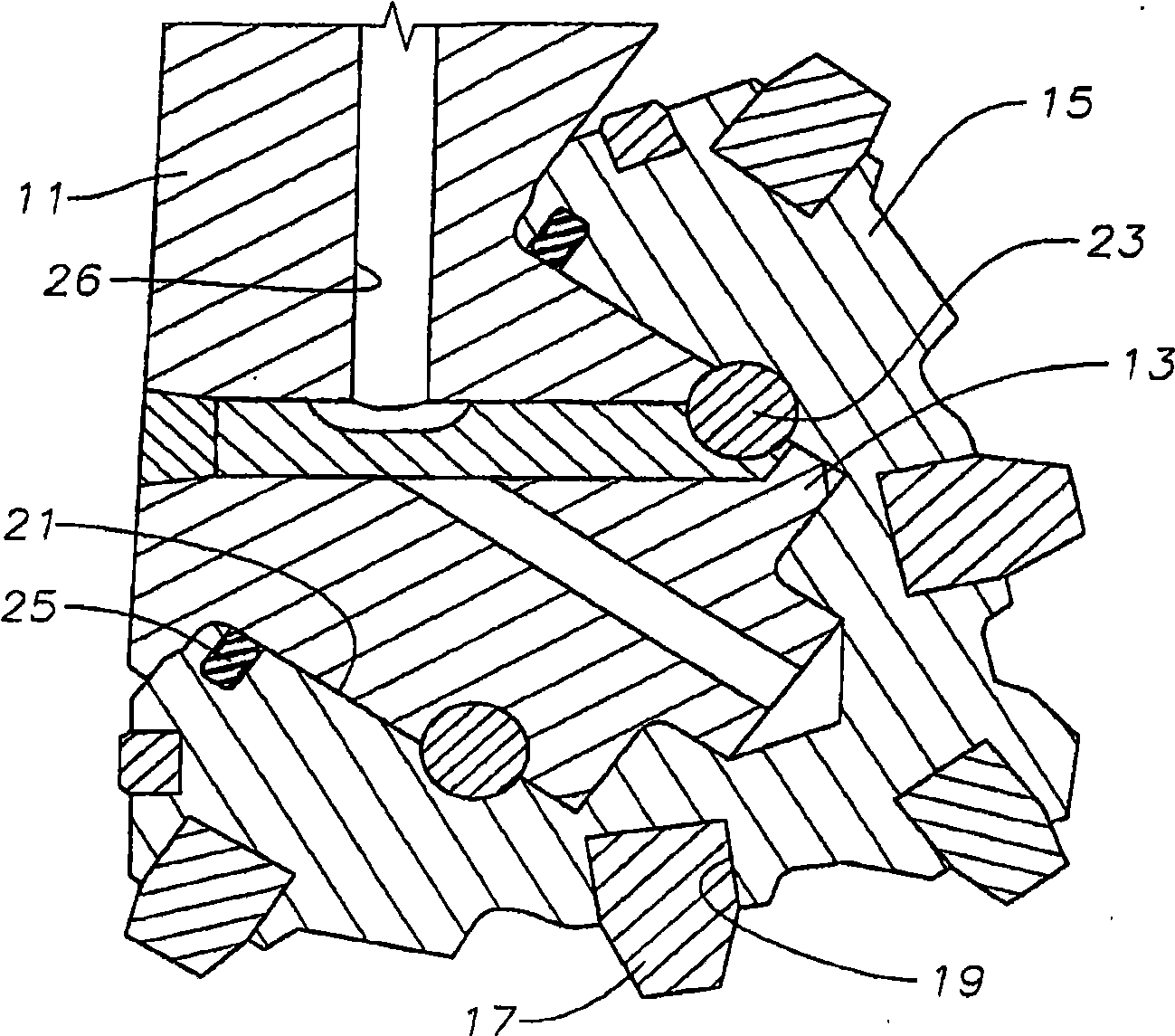

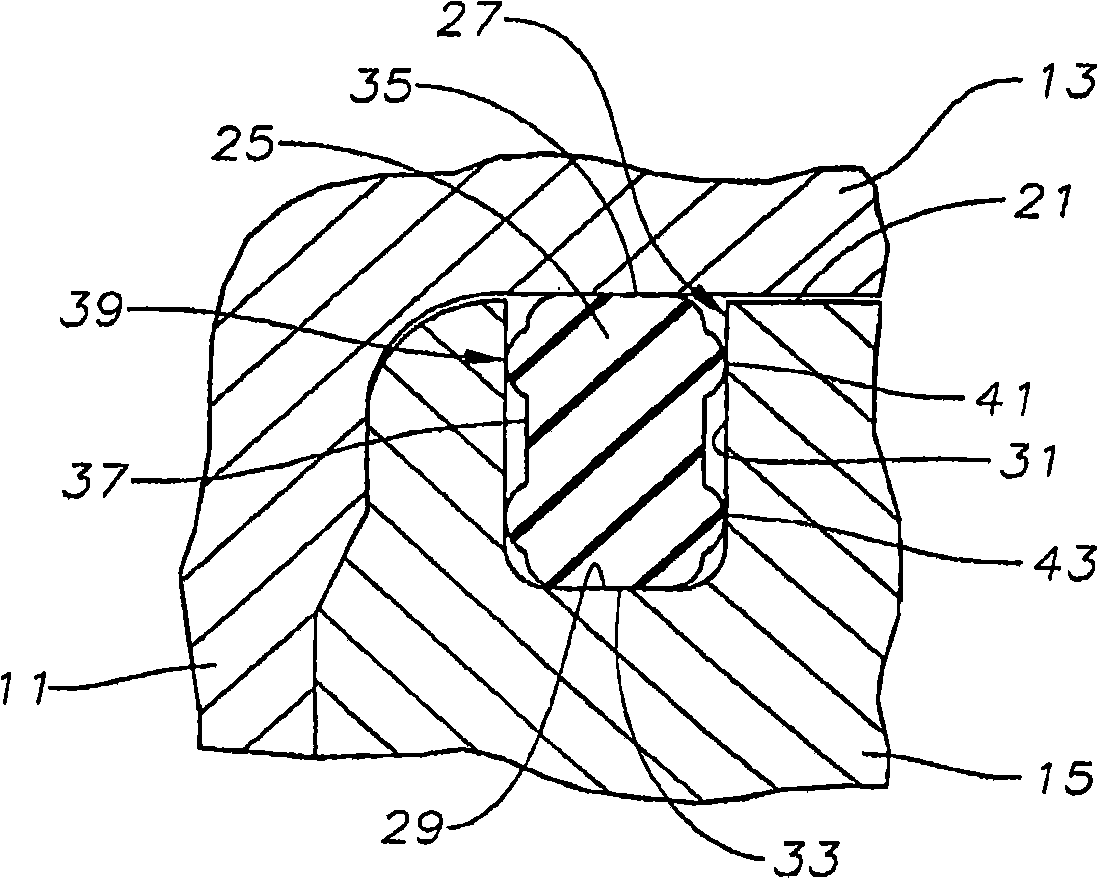

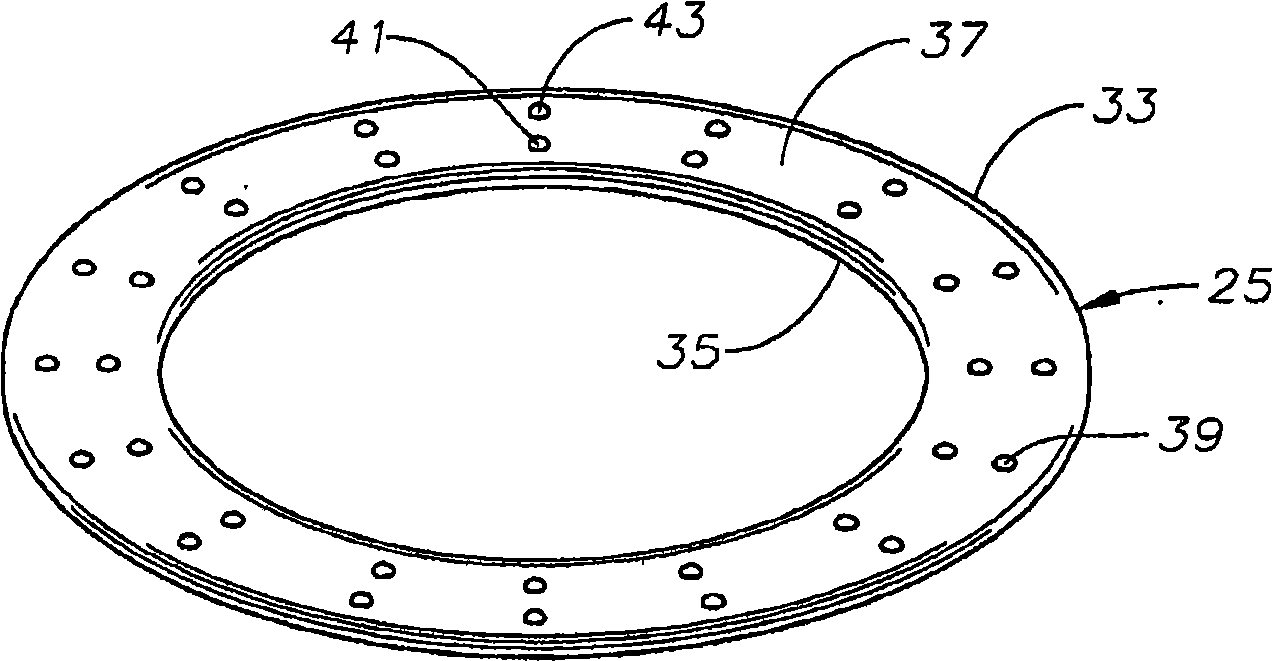

[0015] see figure 1 , the bit has a bit body 11 which typically has three suspended roller cone bit palms. A cylindrical cone shaft 13 is suspended from each cone bit leg of the bit body 11 . A cone 15 having a plurality of cutting elements 17 is rotatably mounted on the cone shaft 13 . In this example, the cutting element 17 comprises a tungsten carbide insert inserted in a mating hole 19 . Alternatively, the cutting elements 17 may comprise teeth turned into the outer surface of the cone 15 .

[0016] The cone 15 has a cavity with a cylindrical bearing surface 21 . The bearing surface 21 may be integrally formed with the cone 15, or may comprise a sleeve disposed within the cavity of the cone 15, such as by shrink fitting. The cone bearing surface 21 forms a radial bearing surface with the cone shaft 13 . Locking elements 23 , which in this example comprise a plurality of balls, are located in cooperating grooves on the cone shaft 13 and in the cavity of the cone 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com