Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

一种气体混合物、二氧化碳的技术,应用在用于材料和表面科学的纳米技术、有机化合物的制备、从含氧有机化合物制烃等方向,能够解决有效性降低等问题,达到解决腐蚀和蒸发问题的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

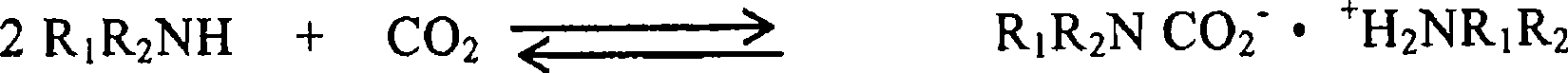

Method used

Image

Examples

Embodiment I

[0049] Example 1. Preparation of Loaded Amine Sorbent

[0050] This example illustrates that 50wt% polyethyleneimine and 50wt% have an average primary particle size of 7nm and 390m 2 / g+ / -40m 2 Preparation of supported amine sorbent composed of fumed silica with specific surface area / g.

[0051] 4 g of polyethyleneimine (molecular weight Mw of 25,000) was dissolved in 25 mL of methanol. This solution was then added dropwise to 4 g of fumed silica suspended in 100 mL of methanol with stirring to ensure good dispersion of polyethyleneimine on the support. The mixture was stirred for a further 1 hour, and then the solvent was removed from the mixture by heating under vacuum at 50 °C on a rotovap followed by overnight vacuum (<1 mmHg). The resulting supported amine sorbent was a white solid which was then crushed and sieved to obtain a homogeneous powder.

Embodiment II

[0052] Example II. Preparation of Supported Amine / Polyol Sorbent

[0053] This example illustrates that 45wt% polyethyleneimine, 10wt% polyethylene glycol and 45wt% have an average primary particle size of 7nm, 390m 2 / g+ / -40m 2 Preparation of supported amine / polyol sorbents composed of fumed silica with specific surface area / g.

[0054] Polyethylene glycol (molecular weight Mw of 400) 2 g was dissolved in 25 mL methanol. This solution was then added dropwise to 9 g of fumed silica suspended in 200 mL of methanol with stirring to ensure good dispersion of polyethylene glycol on the support. The mixture was then stirred for a further 1 hour. The solvent was then removed from the mixture by heating under vacuum at 50 °C on a rotary evaporator followed by overnight vacuum (<1 mmHg). The resulting polyol / carrier was a white powder which was crushed and sieved.

[0055] 5.5 g of the resulting polyol / carrier were mixed with 50 mL of methanol. To this mixture was added dropwise...

Embodiment III

[0056] Example III. Preparation of Supported Amine / Polyol Sorbent

[0057] The same procedure described in Example II was used to prepare a pyrolyzed compound consisting of 47.5 wt% polyethyleneimine (molecular weight Mw of 25,000), 10 wt% polyethylene glycol (molecular weight Mw of 400), and 42.5 wt% Sorbent composed of silica. The resulting polyol / amine supported sorbent was a white solid which was ground and sieved to produce a homogeneous powder. The powder has excellent flow properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com