Method and structure for glue injection and holding when assembling bearing for motor

A kind of bearing and glue injection technology, which is used in electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve problems such as damaged bearings, loose bearings, and poor control of glue dosage, so as to avoid damage and cooperate with each other. The effect of improving the degree of noise and vibration and reducing the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

[0017] refer to figure 1 and figure 2 , the present invention proposes a method of glue injection and holding when the motor is assembled with bearings, comprising steps:

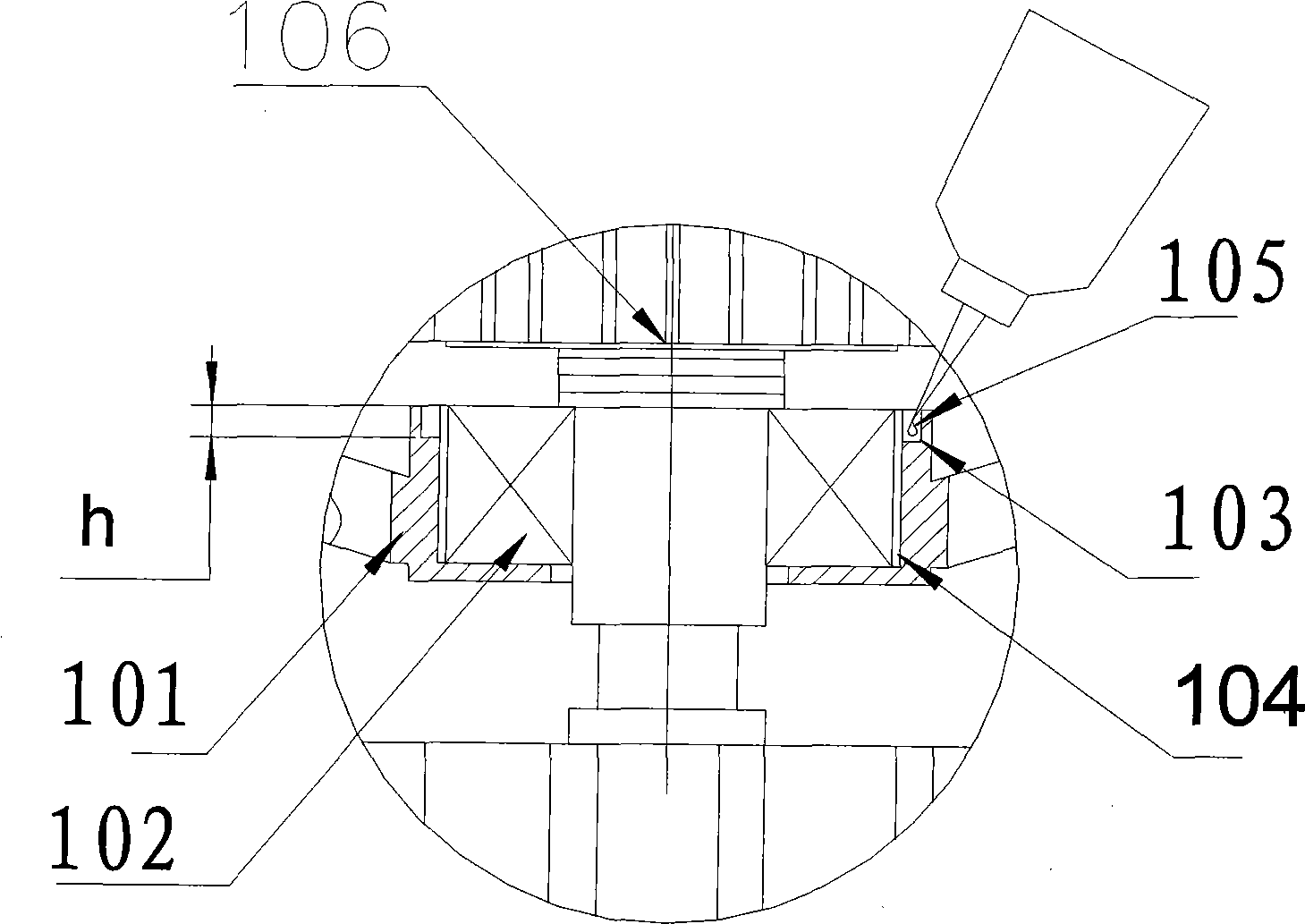

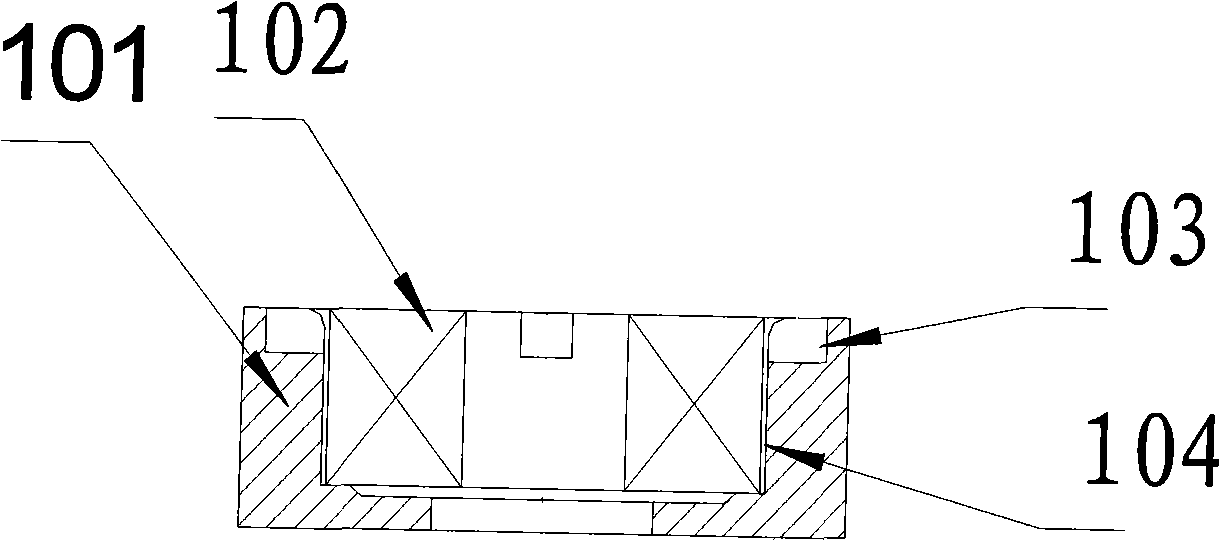

[0018] A. On the inner side of the motor end cover with clearance fit bearing chamber 101, on the upper edge of the ring wall of the bearing chamber 101, set 2 to 4 glue injection gaps 103 at equal intervals;

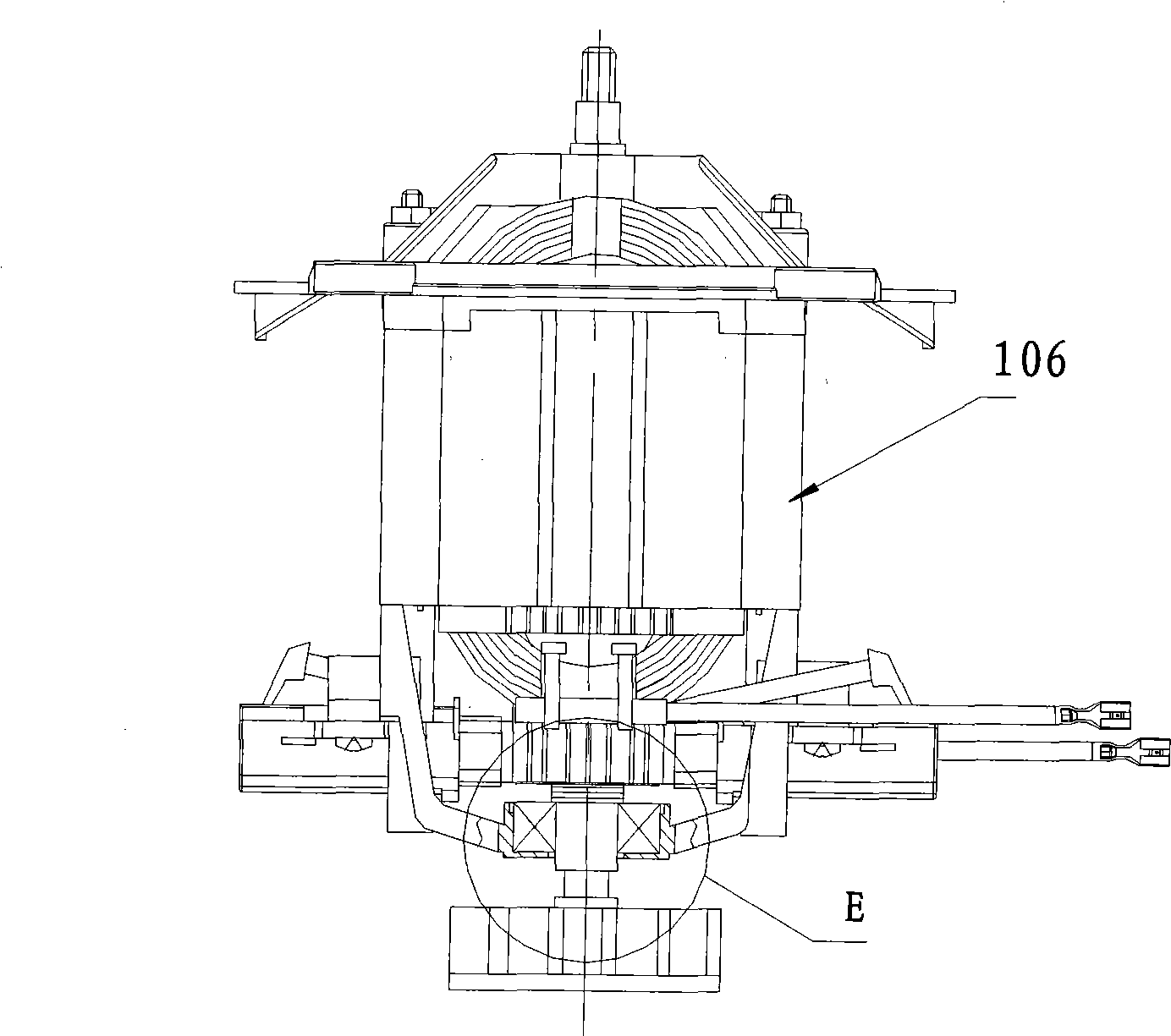

[0019] B. Assembling the motor end cover loaded with the bearing 102 onto the motor 106, completing all assembly and straightening procedures;

[0020] C. drip glue 105 from each glue injection gap 103 around the bearing chamber 101 through each ventilation hole on the end cover;

[0021] D. After the glue in the glue injection gap 103 completely seeps into the gap 104 between the bearing chamber and the bearing outer ring, the excess glue will remain in the glue inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com