Pyramid prism fixing device and method

A corner cube prism and fixing device technology, applied in installation, optics, instruments and other directions, can solve the problems of inability to fix, not easy to fasten the corner cube prism, etc., and achieve the effects of high installation accuracy, protection of the working plane, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

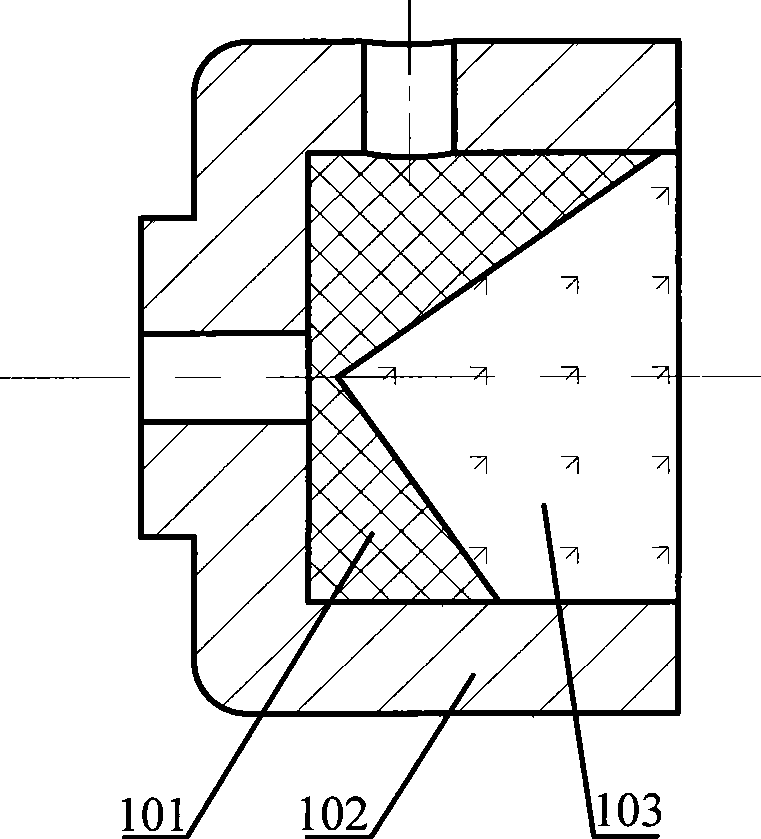

[0038] refer to Figure 5 , the fixing device of the corner cube prism includes a lock nut 501 , a rubber ring 502 , a clamp 504 , a base 505 and a set screw 506 . According to the positional relationship from the inside to the outside, the clamp 504 , the corner cube prism 503 , the rubber ring 502 and the locking nut 501 are located inside the base 505 in sequence.

[0039] refer to Figure 6 , there is a hollow hole 601 at the inner center of the fixture 504, the hole is hexagonal, and its cross section is a regular hexagon, the circumscribed circle diameter of the hollow hole is less than the diameter of the bottom surface of the corner cube prism 503; at the center of the bottom 603 of the fixture 504 A through hole 602 is opened. combine Figure 7 , the clamp 504 utilizes the end face vertex 701 of the hollow hole and the corner cube edge 702 to clamp together in a point contact manner, the through hole 602 is used to accommodate the tip of the corner cube, and the co...

no. 2 Embodiment

[0053] Such as Figure 9 As shown in (a), on the basis of the first embodiment, the hollow hole inside the fixture 504 is changed into a through hole that runs through the whole fixture, and a through hole is opened at the bottom of the base 505, and other parts are the same as the first embodiment. Two corner cubes can be fixed at the same time.

[0054] Such as Figure 9 As shown in (a), the corner cube fixing device includes a locking nut 901 , a rubber ring 902 , a clamp 904 , a base 905 and a set screw 906 . According to the positional relationship from the inside to the outside, the rubber ring 902 , the corner cube prism 903 , the fixture 904 , the corner cube prism 903 , the rubber ring 902 and the locking nut 901 are located inside the base 905 in sequence.

[0055] refer to Figure 9 (b), clamp 904 inner center is a through hole 907, and this through hole is hexagonal column shape, and its cross section is regular hexagon, and the circumscribed circle diameter of ...

no. 3 Embodiment

[0066] On the basis of the first embodiment, the hollow hole of the hexagonal prism of the fixture 504 is changed into the hollow hole of the hexagonal pyramid, and other parts are the same as the first embodiment, and this embodiment can be obtained. Contact-mounted corner cubes.

[0067] refer to Figure 10 , the corner cube fixing device includes a lock nut 1001 , a rubber ring 1002 , a clamp 1004 , a base 1005 and a screw 1006 . According to the positional relationship from the inside to the outside, the clamp 1004 , the corner cube prism 1003 , the rubber ring 1002 , and the locking nut 1001 are located inside the base 1005 in sequence.

[0068] refer to Figure 11 , there is a hollow hole 1101 at the inner center of the clamp 1004, which is a hexagonal pyramid hole and includes six ridgelines 1103, the ridgelines separated by two pairs are perpendicular to each other, the cross section of the hollow hole is a regular hexagon, and the hollow hole The diameter of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com