Technique for cultivating Hemifusus tuba

A breeding technology, the technology of snails, is applied in the field of snail culture technology, to achieve the effects of reducing the occurrence of diseases, facilitating growth, and improving survival rate and growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

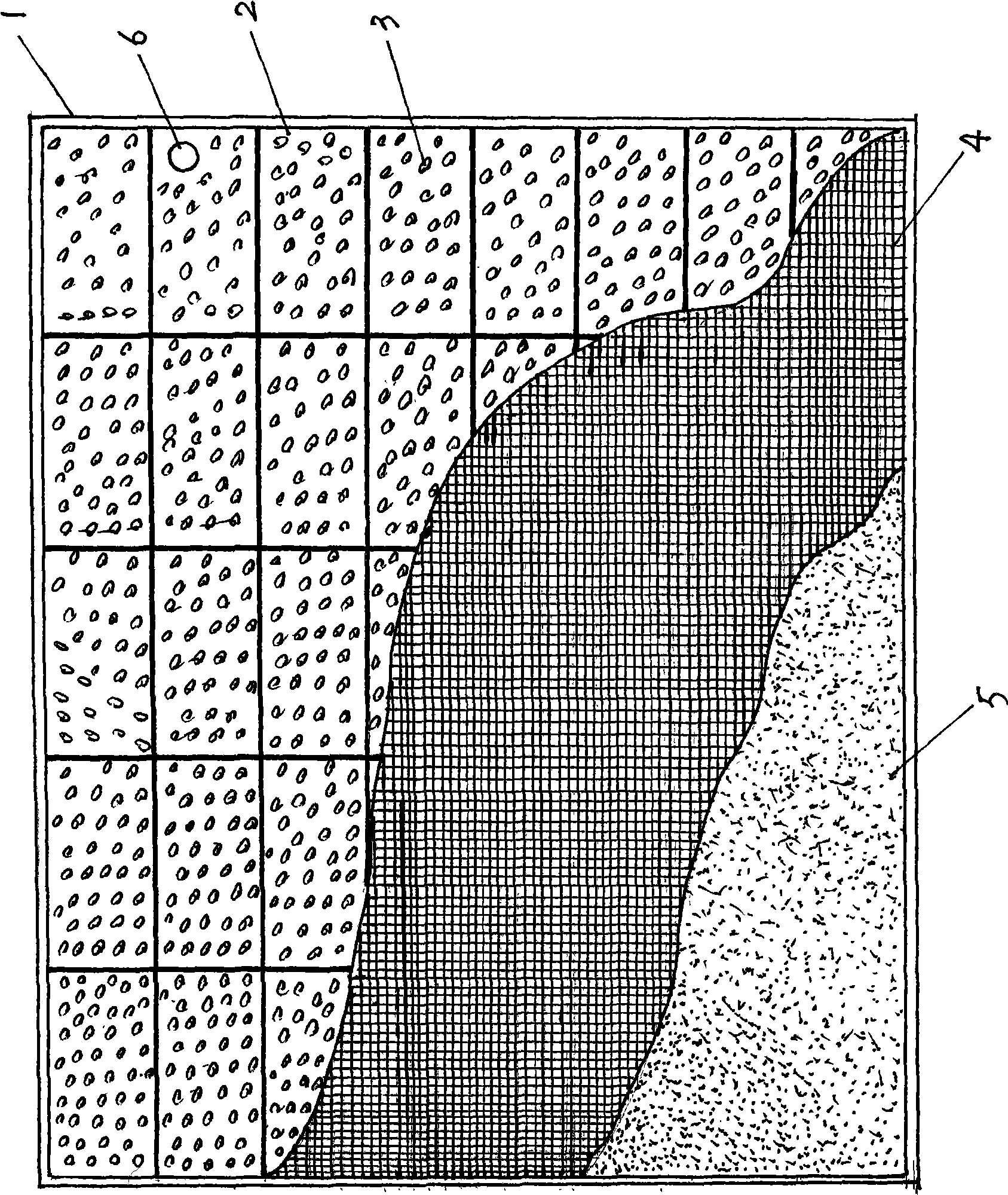

[0012] like figure 1 As shown, using a length of 5 meters, a width of 4 meters, and a bottom area of 20m 2 1. Deep 1.2m breeding pond 1 (being the cultivation pond of original abalone fry or shrimp seedlings), laying 40 long 100cm, wide 50cm cement boards 2 at its bottom, be covered with through holes 3 on the cement board 2, cement The board must be raised by 20cm, so that a space about 20cm high is formed between the bottom of the pool and the cement board; a plastic water pipe 6 is connected to the water inlet to reach the bottom of the pool, and there is a drainage hole at the bottom of the pool. A 70cm-high plastic water pipe perpendicular to the water surface is connected to one end of the water pipe as a drainage pipe; an 80-mesh mesh cloth 4 is laid on the cement board 2 to prevent the fine sand from falling to the bottom of the pool, and then a 20cm-thick fine sand is laid on the mesh cloth 4. Sand 5. The size of the sand should be moderate. If the sand is too fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com