Teeth bar structure of optical disk driver

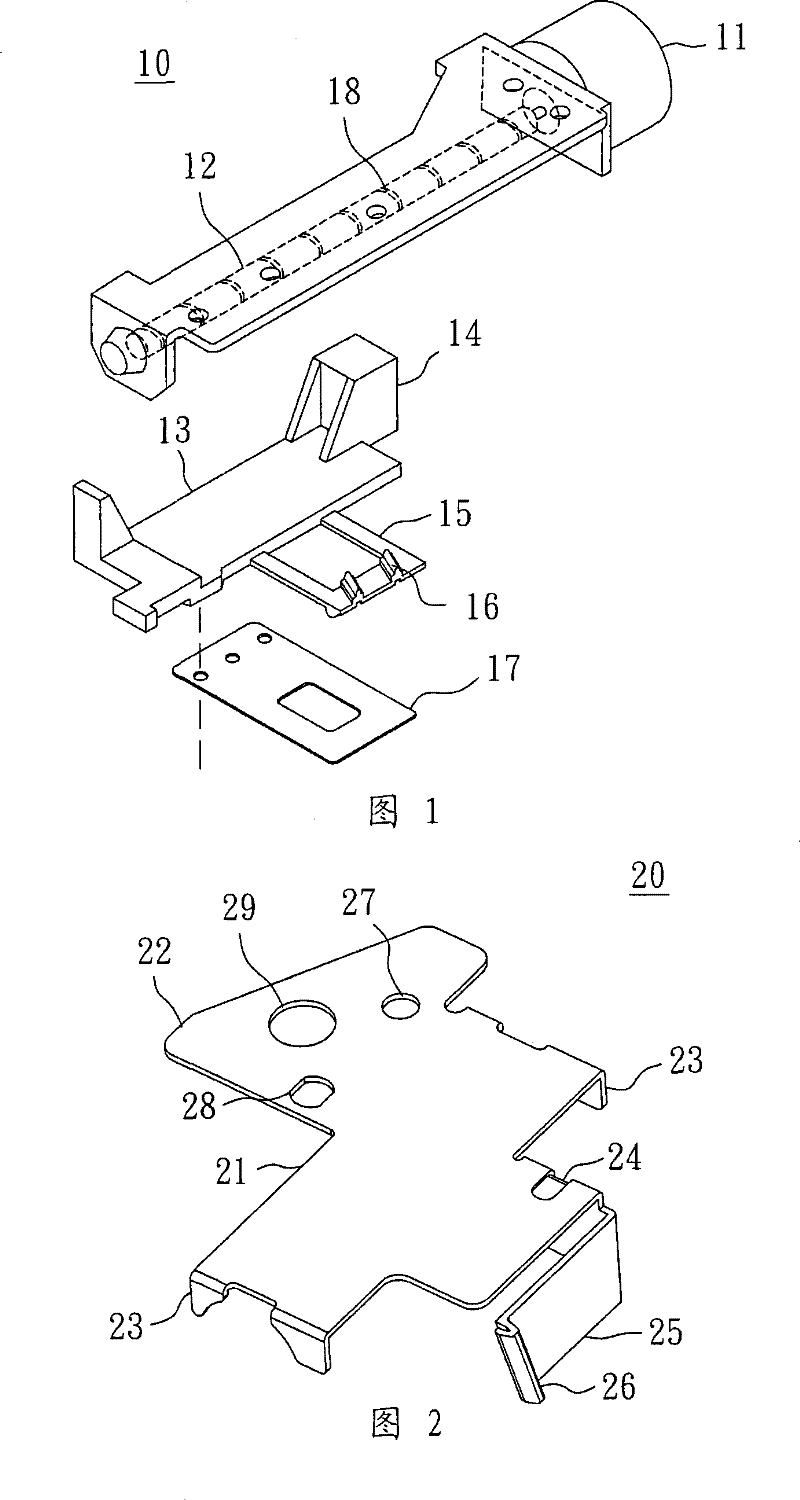

A technology of optical disc drives and racks, which is applied to instruments, recording/reproducing with optical methods, head configuration/installation, etc. It can solve the problems of difficult manufacturing, inaccurate precision, waste of manufacturing and assembly time, and parts costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The technical means adopted to realize the object of the present invention and their effects will be described below in conjunction with the accompanying drawings by taking preferred embodiments as examples.

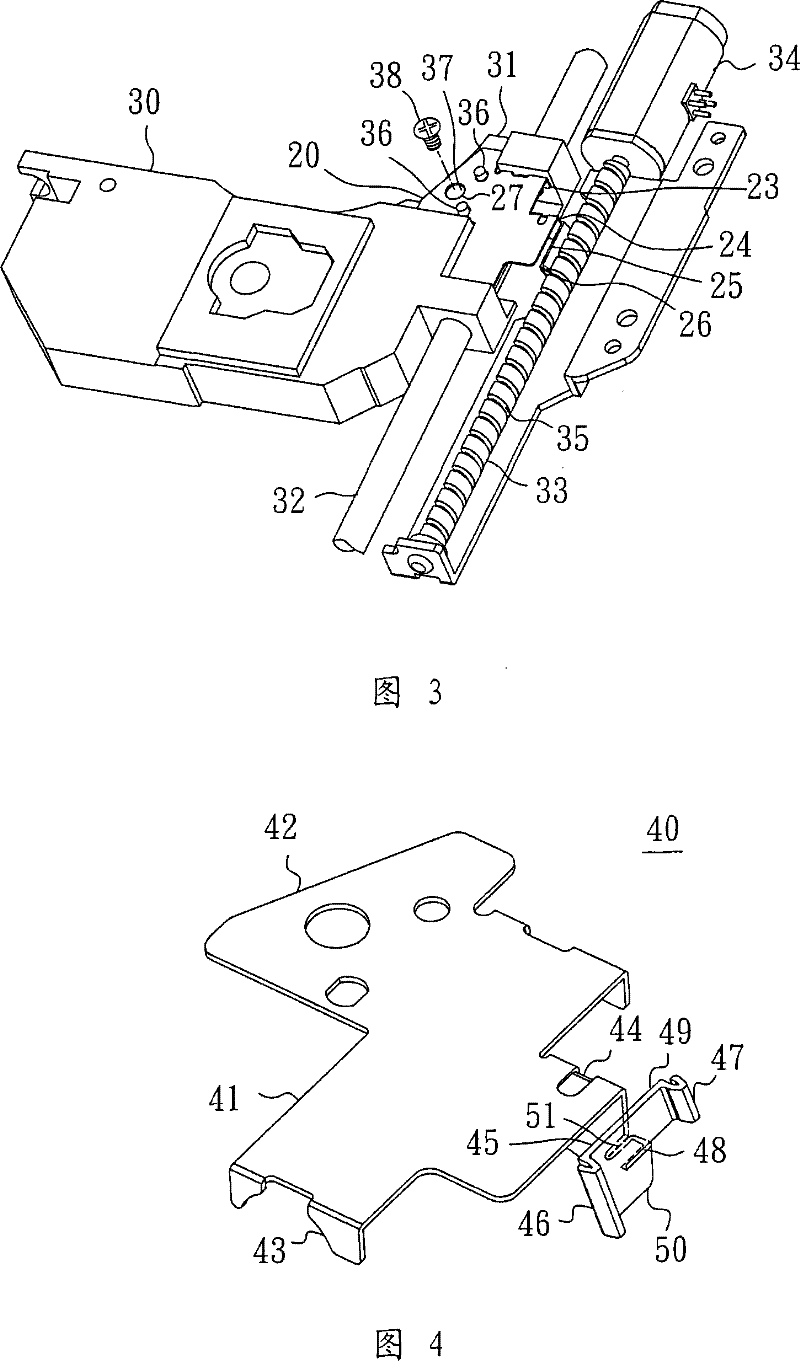

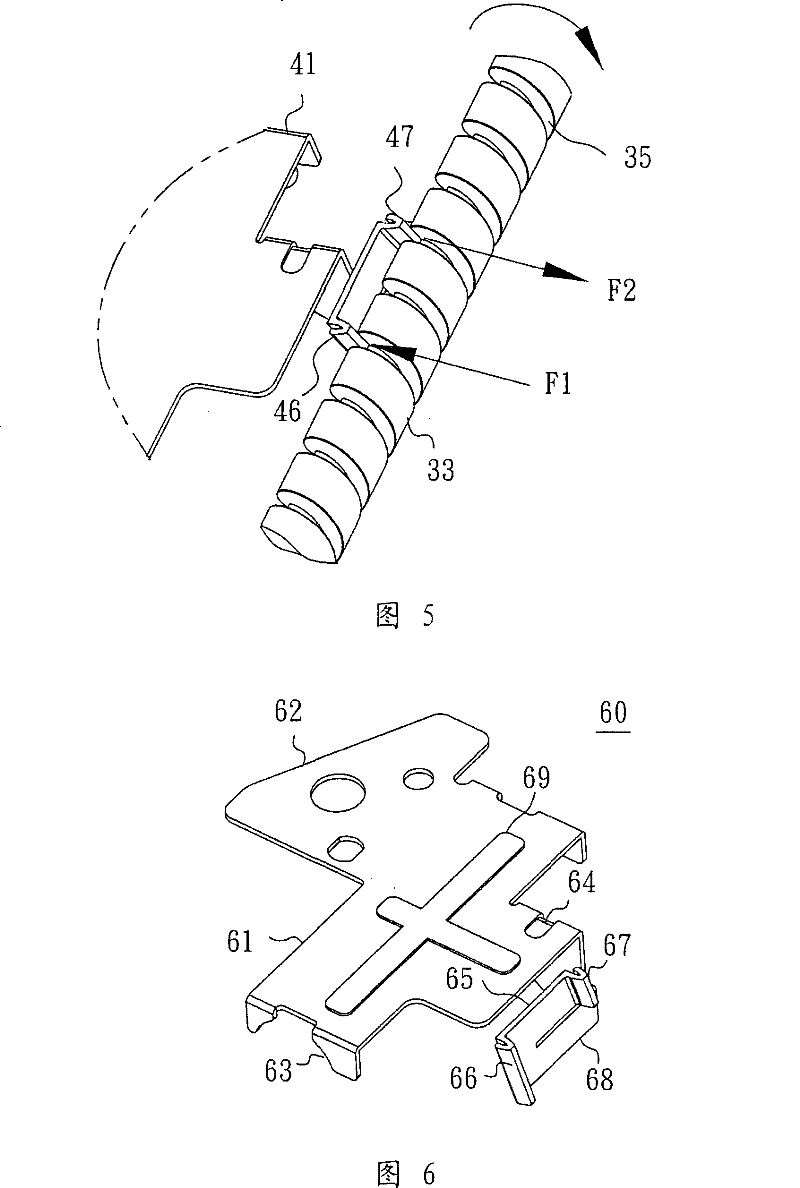

[0080] Please refer to figure 2 , which shows the rack structure 20 of the optical disc drive according to the first embodiment of the present invention. The rack structure 20 is integrally formed by stamping a metal plate, and includes a body 21 , a fixing portion 22 , a support frame 23 , a reinforcing body 24 , an elastic frame 25 and a rack 26 . The elastic frame 25 is mainly extended from the reinforcing body 24 at the front end of the main body 21, and the rack 26 is arranged on the elastic frame 25. The side of the main body 21 forms a support frame 23. Joint 31 (please refer to image 3 ) to form a link.

[0081] Wherein, the body 21 is in the shape of a flat plate for fixing to the joint portion 31 of the read head 30 , and its shape can be changed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com