Calibration test apparatus for extra-high voltage direct current transformer

A current transformer, UHV DC technology, applied in the field of calibration test devices, can solve the problems of not reflecting the operating conditions of the transformer, lack of calibration methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The calibration test device of the UHV DC current transformer of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

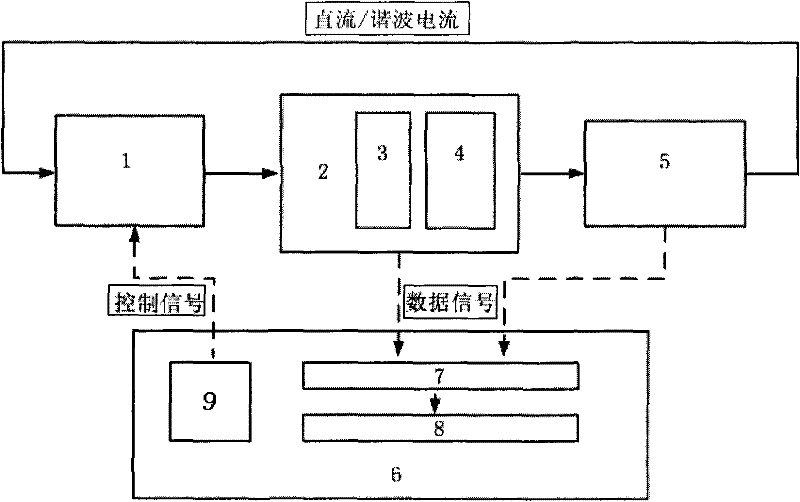

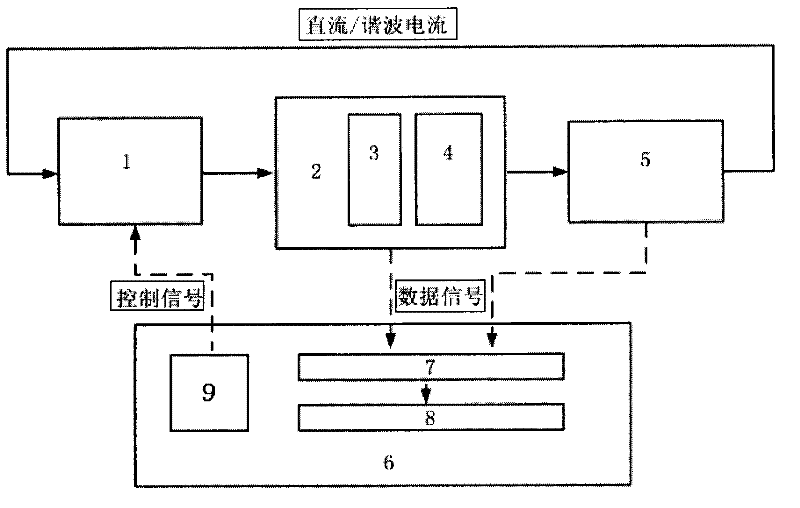

[0008] figure 1 Marks in: 1-AC-DC program control power supply, 2-calibration sensor, 3-zero magnetic flux sensor, 4-broadband current sensor, 5-DC current transformer to be calibrated, 6-data processing and control device, 7-signal processing unit, 8-error measurement calculation unit, 9-system control unit.

[0009] Such as figure 1 As shown, the embodiment of the present invention includes an AC-DC program control power supply 1, a calibration sensor 2 and a data processing and control device 6, the calibration sensor 2 includes two sensing heads of a zero magnetic flux sensor 3 and a broadband current sensor 4, and a data processing and control device 6 includes a signal processing unit 7, an error measurement calculation unit 8 and a system control unit 9; the test current generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com