Method for measuring nanometer electronic thin film micro-zone piezoelectric coefficient based on atomic microscope

An atomic force microscope and piezoelectric coefficient technology, which is applied in the field of materials, can solve the problems of uneven piezoelectric effect, difficult to accurately detect the number of charges, and limited piezoelectric coefficient in nano-micro area, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

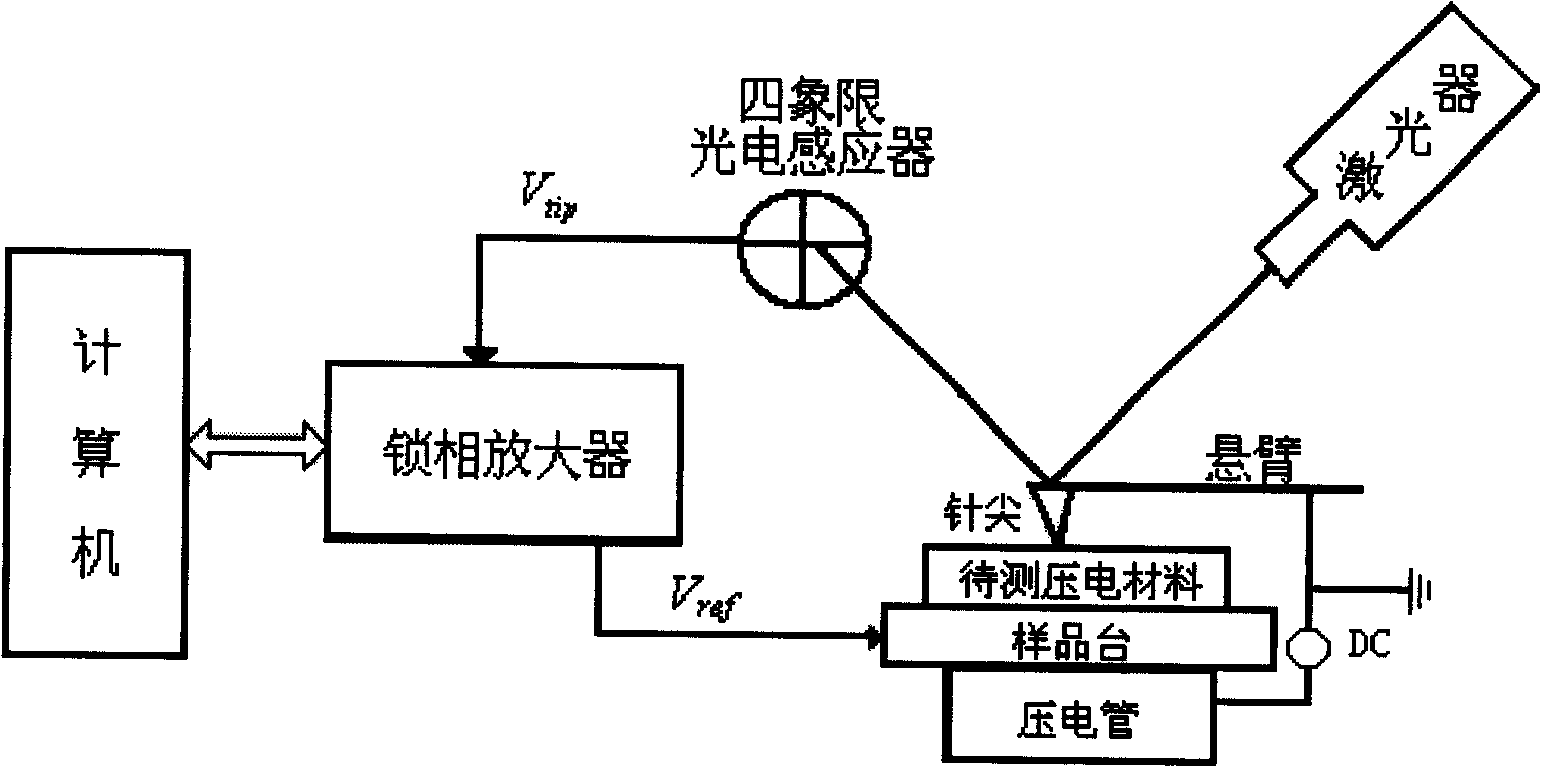

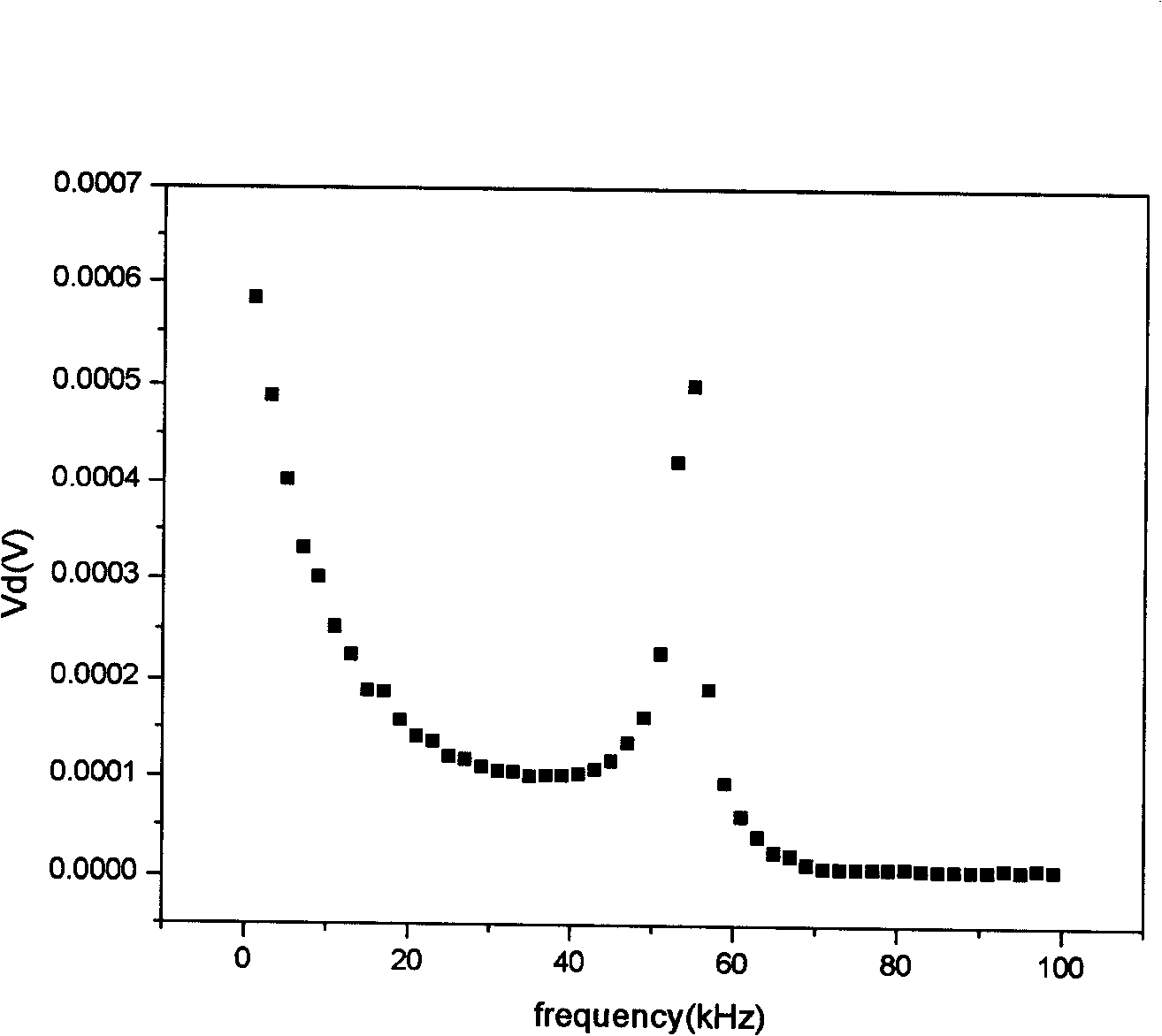

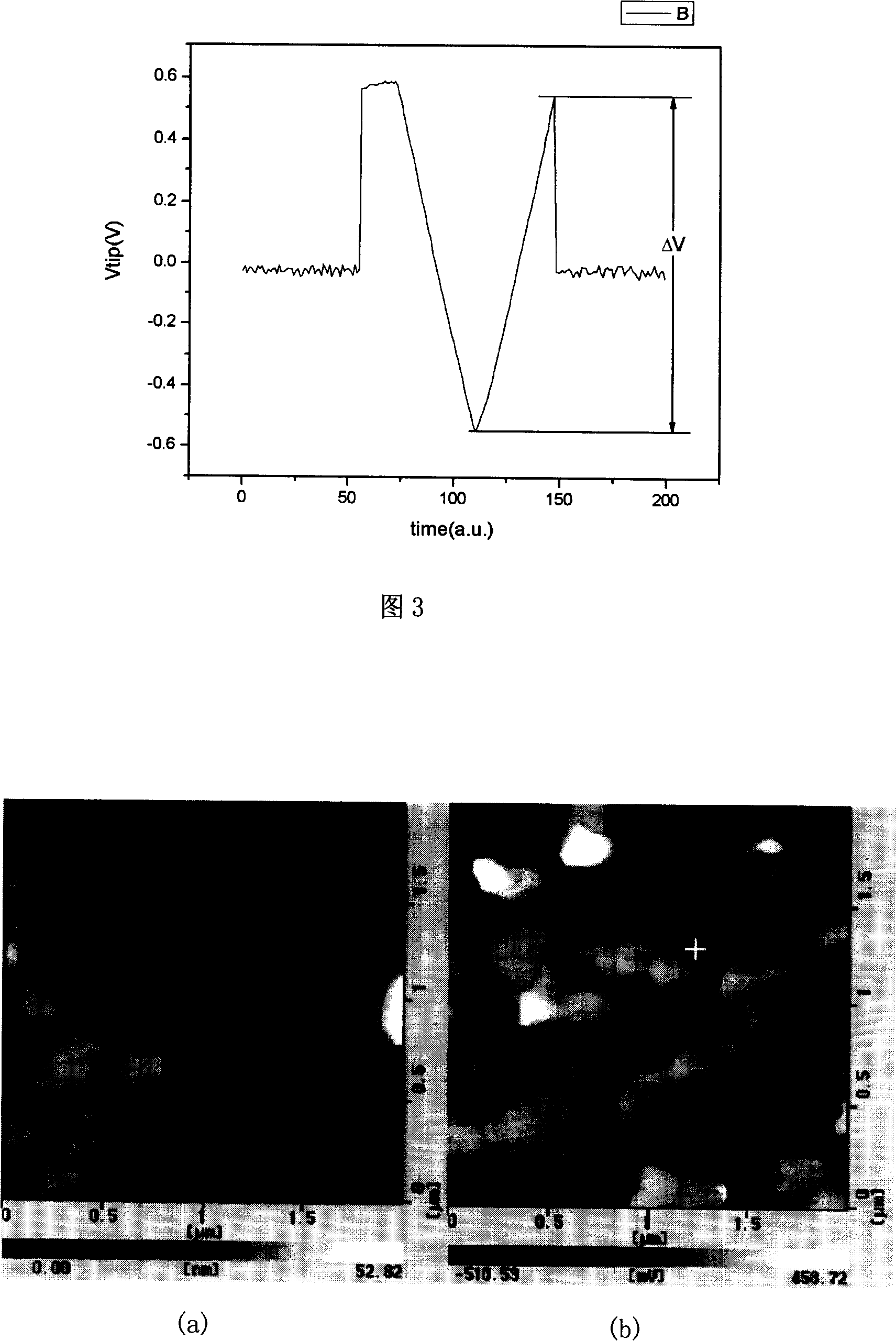

[0027] according to figure 1 The measurement system is built as shown, the computer is connected to the lock-in amplifier SR830 through the GPIB bus, and the internal reference oscillation signal V of the lock-in amplifier is ref It is connected with the conductive sample stage of the atomic force microscope, and the conductive tip of the atomic force microscope is grounded ( figure 1 ). First, calibrate the sensitivity S of the photoelectric sensor. When correcting, first contact the needle tip with the rigid sample, control the piezoelectric tube to move up and down a certain distance H, and measure the voltage change range ΔV through the four-quadrant photoelectric sensor, and then get the sensitivity S=H / ΔV (as shown in Figure 3); then place the piezoelectric material to be measured on the sample stage, and apply the AC voltage V generated by the internal oscillator of the lock-in amplifier between the "conductive needle tip-the piezoelectric material to be measured-samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com