High pressure resistant spring type mechanical sealing device

A mechanical seal device, spring-type technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of easy wear and leakage, and the friction-fit end face is difficult to meet the requirements of high-pressure use, and achieves low power consumption, Good dynamic pressure effect and countercurrent pumping effect, good sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

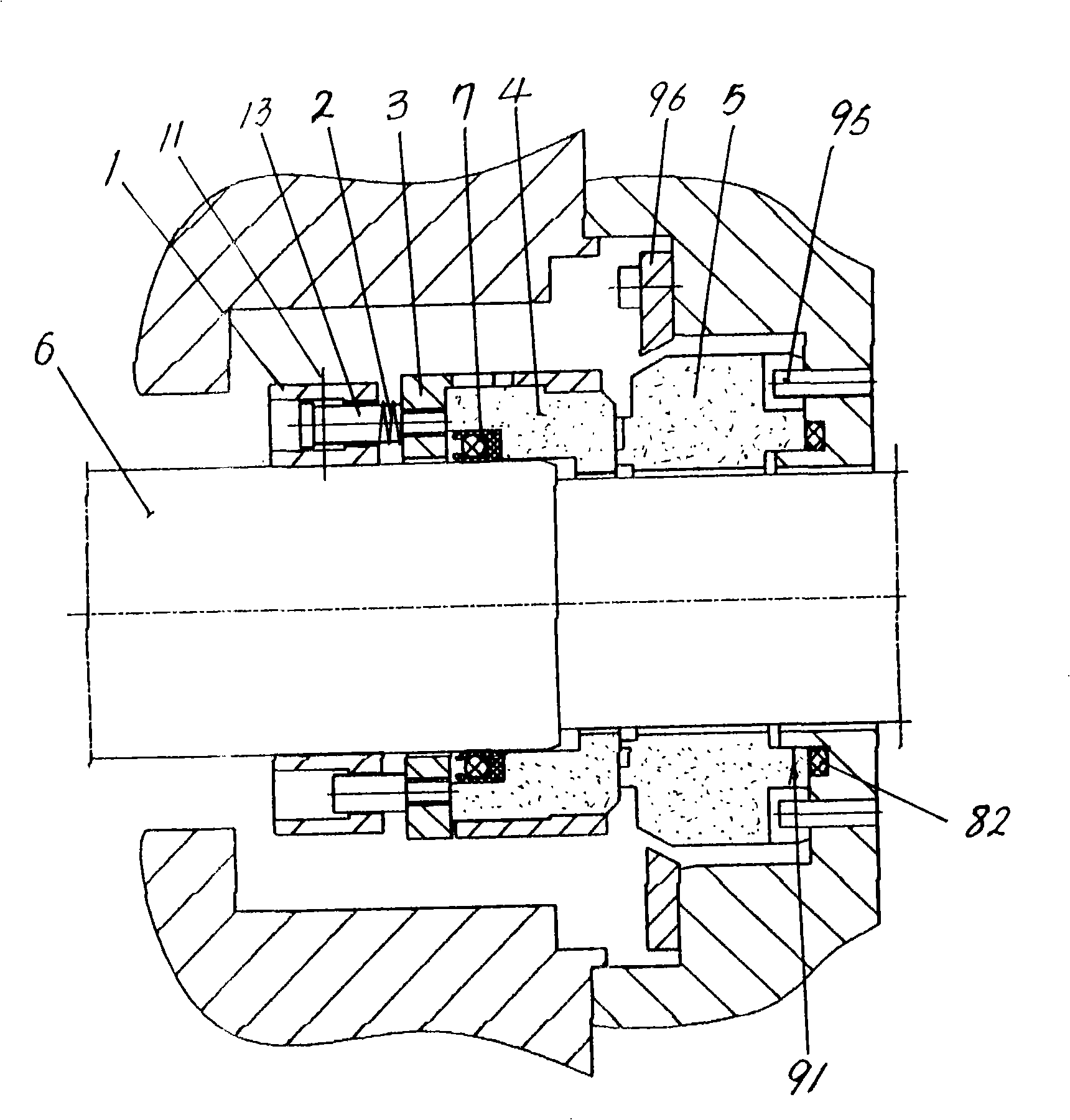

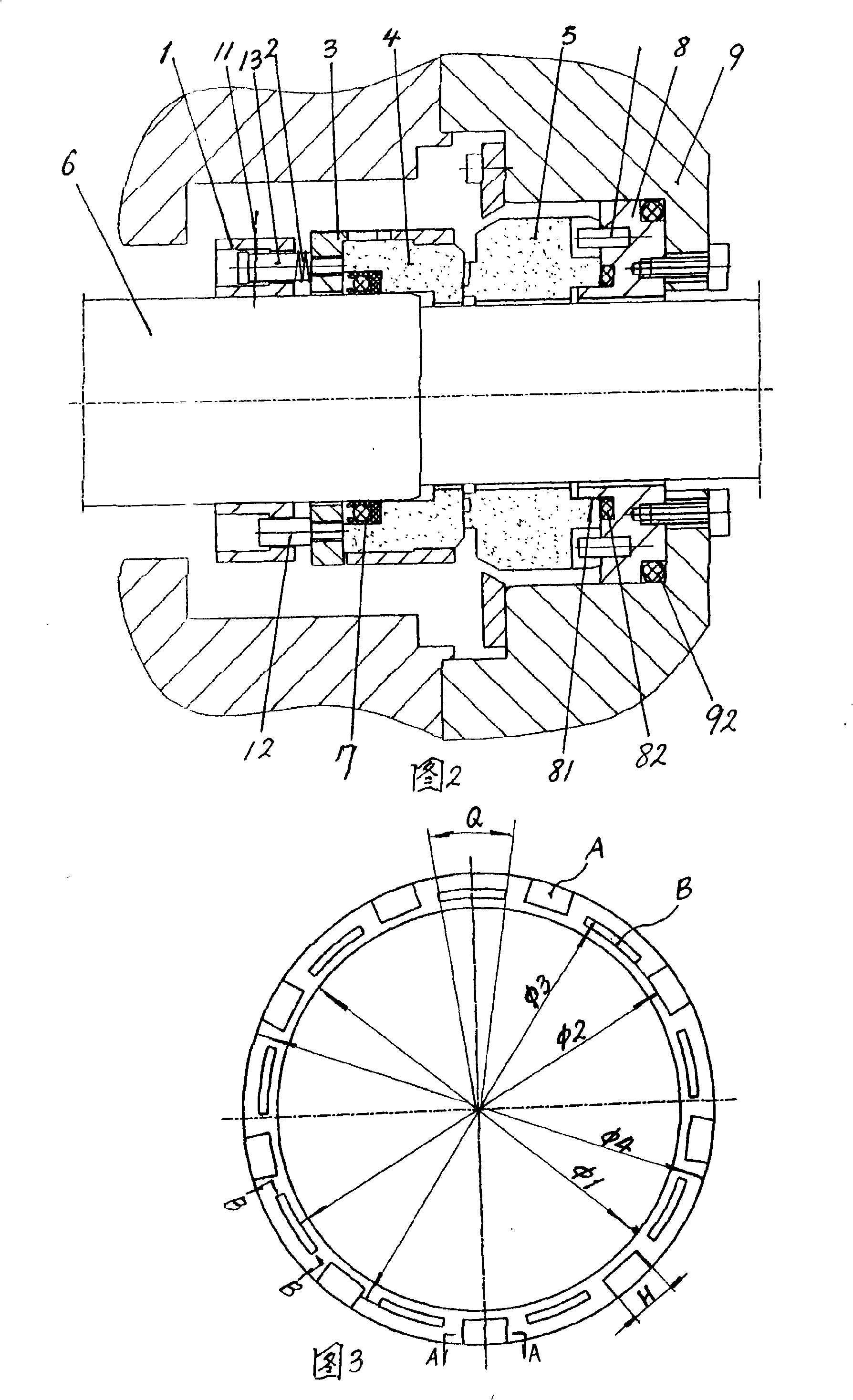

[0023] The present invention includes spring box 1, spring 2, push ring 3, dynamic friction ring 4, static friction ring 5, dynamic friction ring 4 is a compensation ring, spring box 1, push ring 3 are installed on the rotating shaft 6 or the rotating shaft sleeve, the spring box 1 is fixedly connected with the rotating shaft 6 or the rotating sleeve through the fastening screw 11, and an anti-rotation pin 12 is provided between the spring box 1 and the push ring 3, and the spring box 1 and the push ring 3 are connected by sliding fit through the circumferentially distributed pins 13, A thrust spring 2 is set on the pin 13 to push the push ring 3 to make compensation, the compensation ring is the dynamic friction ring 4 installed in the push ring 3, a sliding sealing ring is arranged between the dynamic friction ring 4 and the rotating shaft 6 or the rotating shaft sleeve, and the static friction ring 5 Cooperate with the gland 9 and be provided with an auxiliary sealing ring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com