Lifting mechanism

A lifting mechanism and roller technology, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of sudden drop of the LCD screen, heavy weight of the lifting mechanism, poor stability of the lifting mechanism, etc., and achieve compact structure and manufacturing process The effect of mature and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

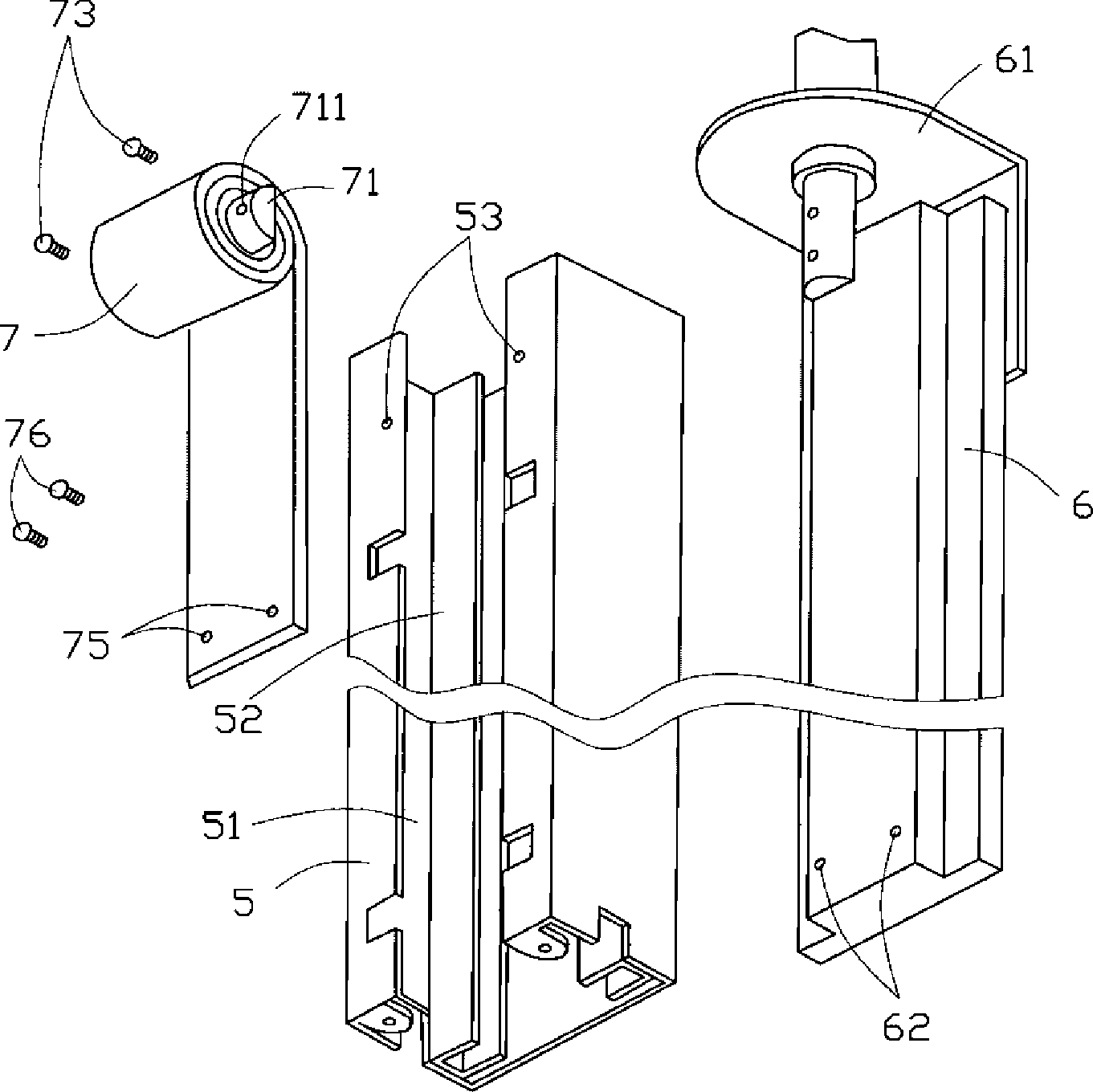

[0013] A preferred embodiment of the present invention is a lifting mechanism, which is suitable for electronic devices with display screens. In this embodiment, the elevating mechanism applied in the liquid crystal display supporting device is taken as an example for illustration.

[0014] see figure 2 , the liquid crystal display support device 10 includes a lifting mechanism 20, a display support frame 30 and a base 40, wherein the lifting mechanism 20 is connected to the display support frame 30 and the base 40 respectively.

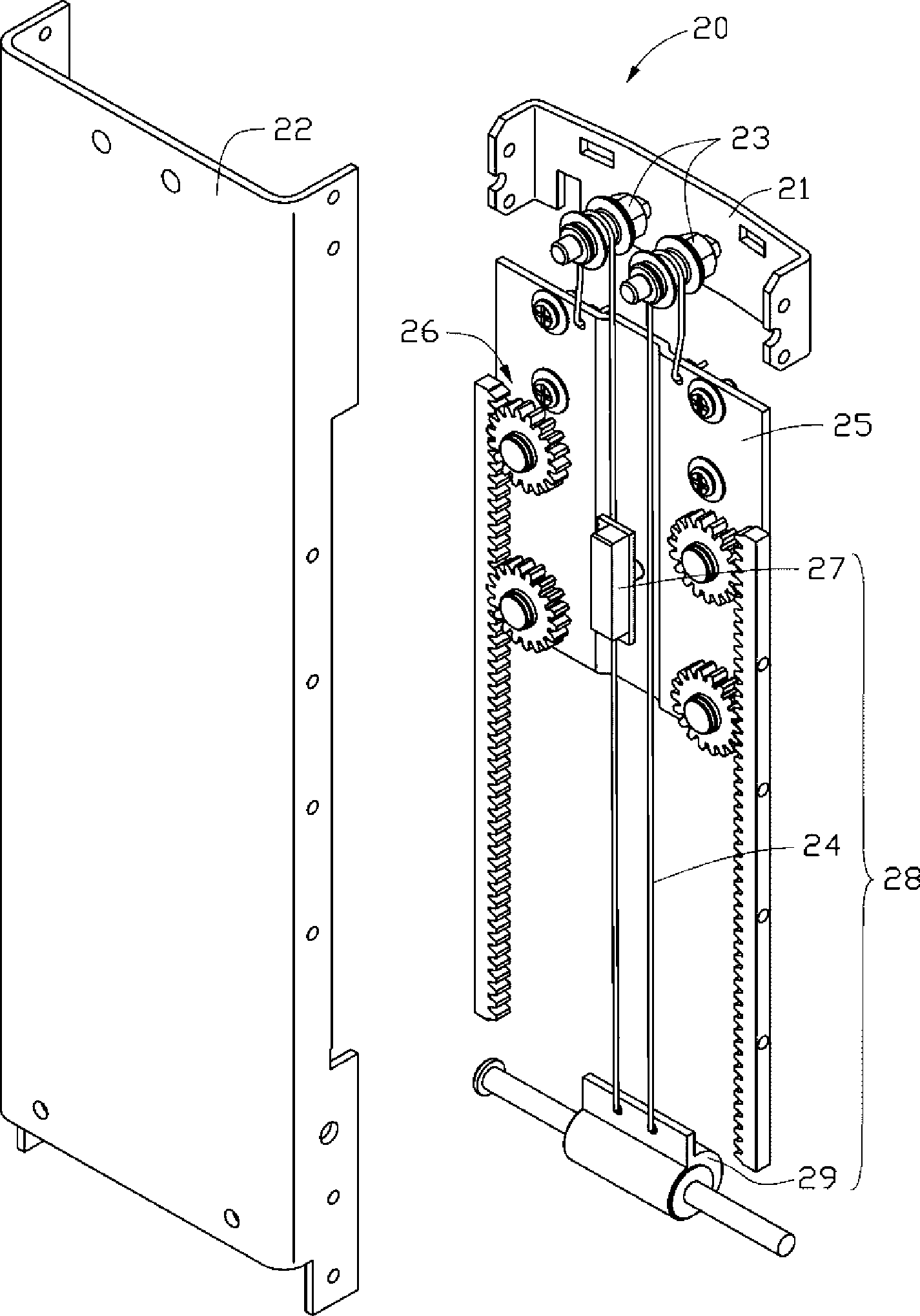

[0015] see image 3 , The lifting mechanism 20 described in this preferred embodiment includes a fixed frame 21 , a bracket 22 , two roller assemblies 23 , a sliding plate 25 , a transmission assembly 26 and a gravity balance device 28 .

[0016] Please also see Figure 4 , the fixing frame 21 includes a rectangular backboard 212 and two side baffles 214 formed by extending from two opposite sides of the backboard 212 perpendicular to the backboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com