Leak stopping method and apparatus for special-shaped sealing surface under temperature and pressure

A special-shaped sealing and plugging method technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of large space in the sealant chamber 4, reduced mechanical strength, uneconomical plugging, etc., and achieves high sealing reliability , safety improvement, and the effect of reducing plugging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention are described as follows:

[0025] Preparation:

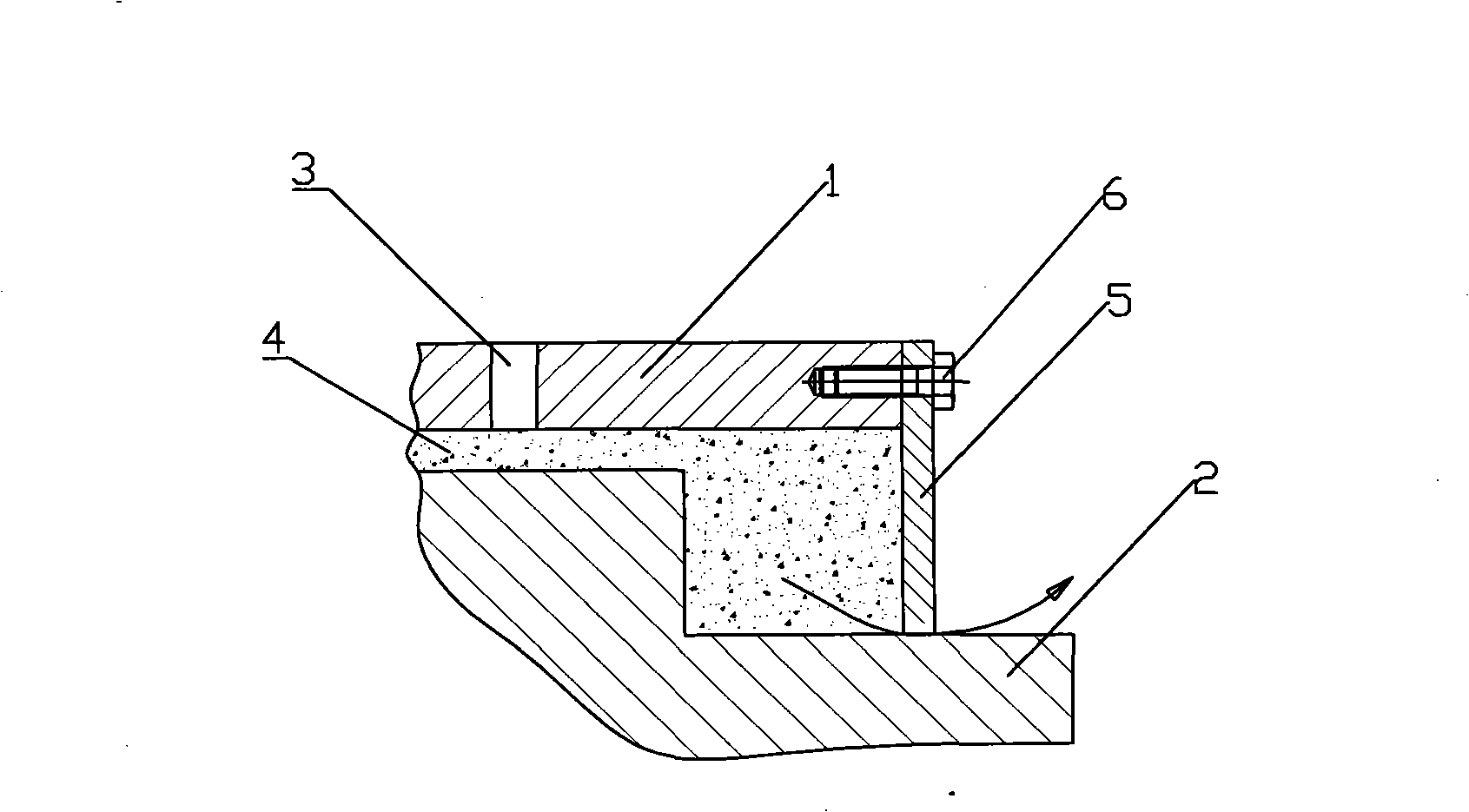

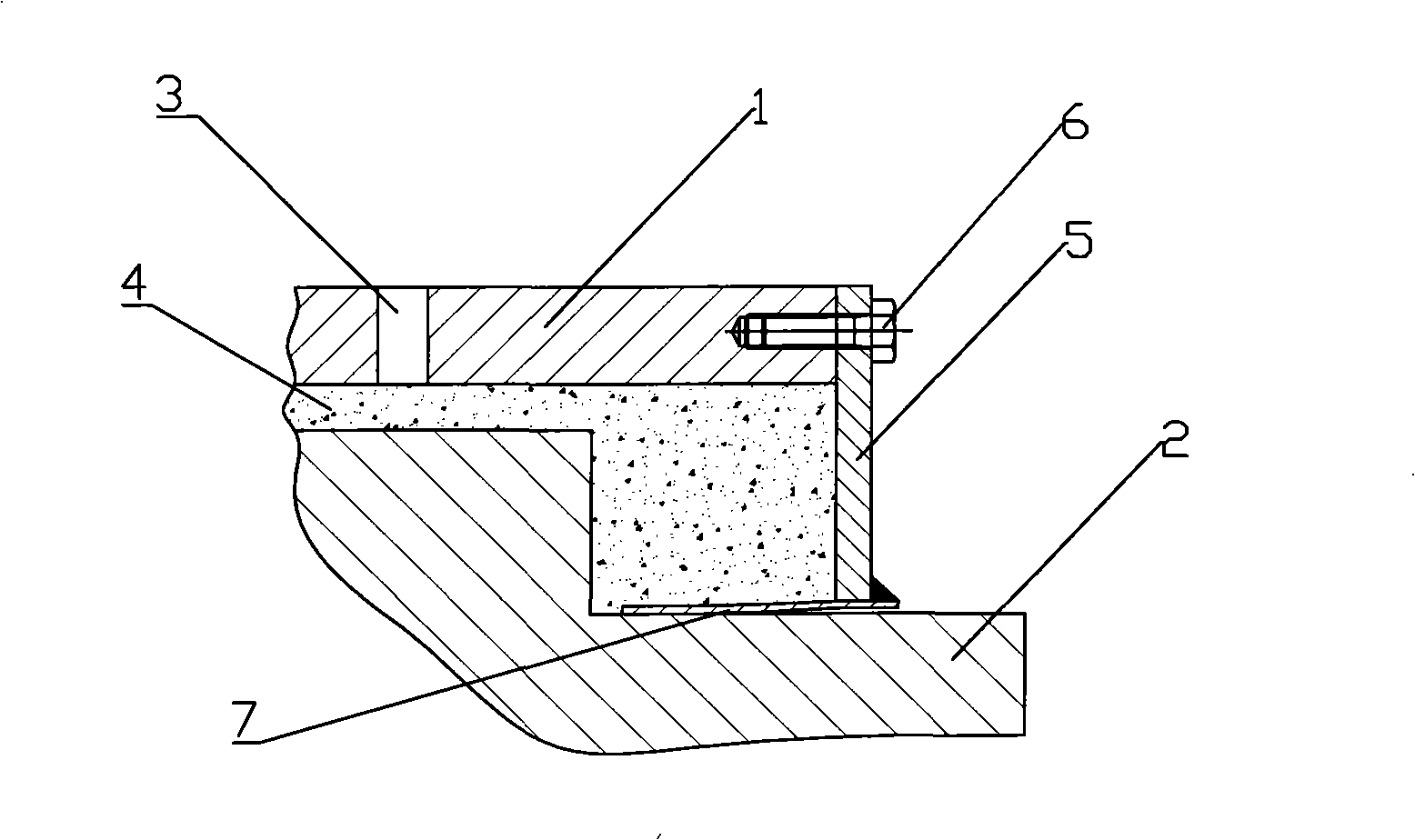

[0026] First, according to the structural size of the leakage point of the sealing surface of the special-shaped structure, a such as Figure 4 The frame-shaped sealing structure 5 shown, and then the frame-shaped sealing structure 5 such as Figure 4 An upper self-sealing soft metal plate 7 is welded at the frame-shaped part shown, and a lower self-sealing soft metal plate 11 is welded at the lower end, and a communication hole 9 is set on the inner leg of the lower end, and then in the frame-shaped A supporting member 12 is welded at the position of the sealing structure 5 as shown in the figure. At the same time, a glue injection hole 3 is preset on the sealing body 1 .

[0027] Plugging process:

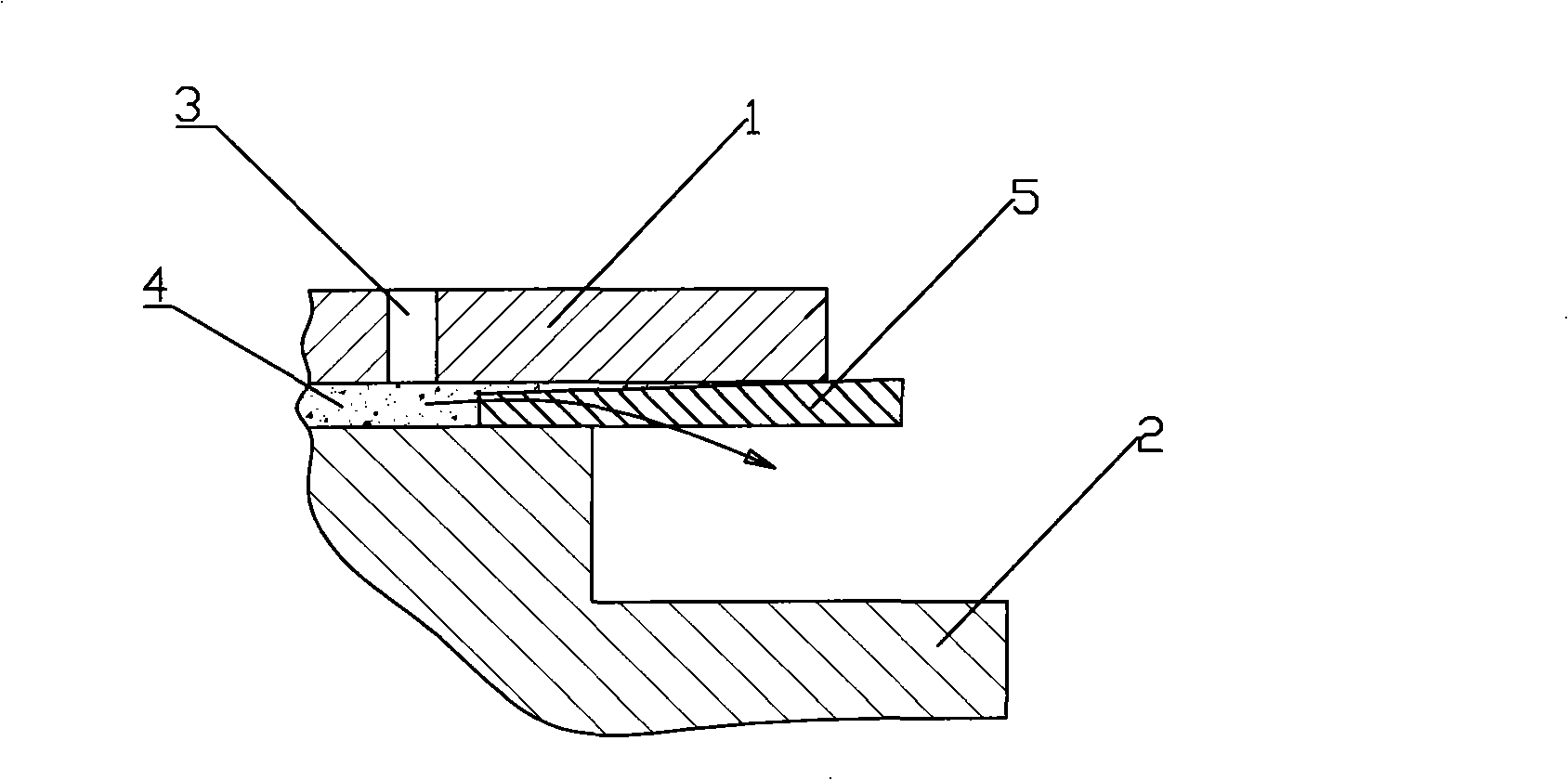

[0028] according to Figure 4 In the position shown, the frame-shaped part of the frame-shaped sealing structure 5 is assembled between the sealing base 2 and the sealing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com