Culture medium for fermenting naringinase, preparation and use method thereof

A technology of culture medium and naringinase, which is applied in the field of culture medium and can solve the problems of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

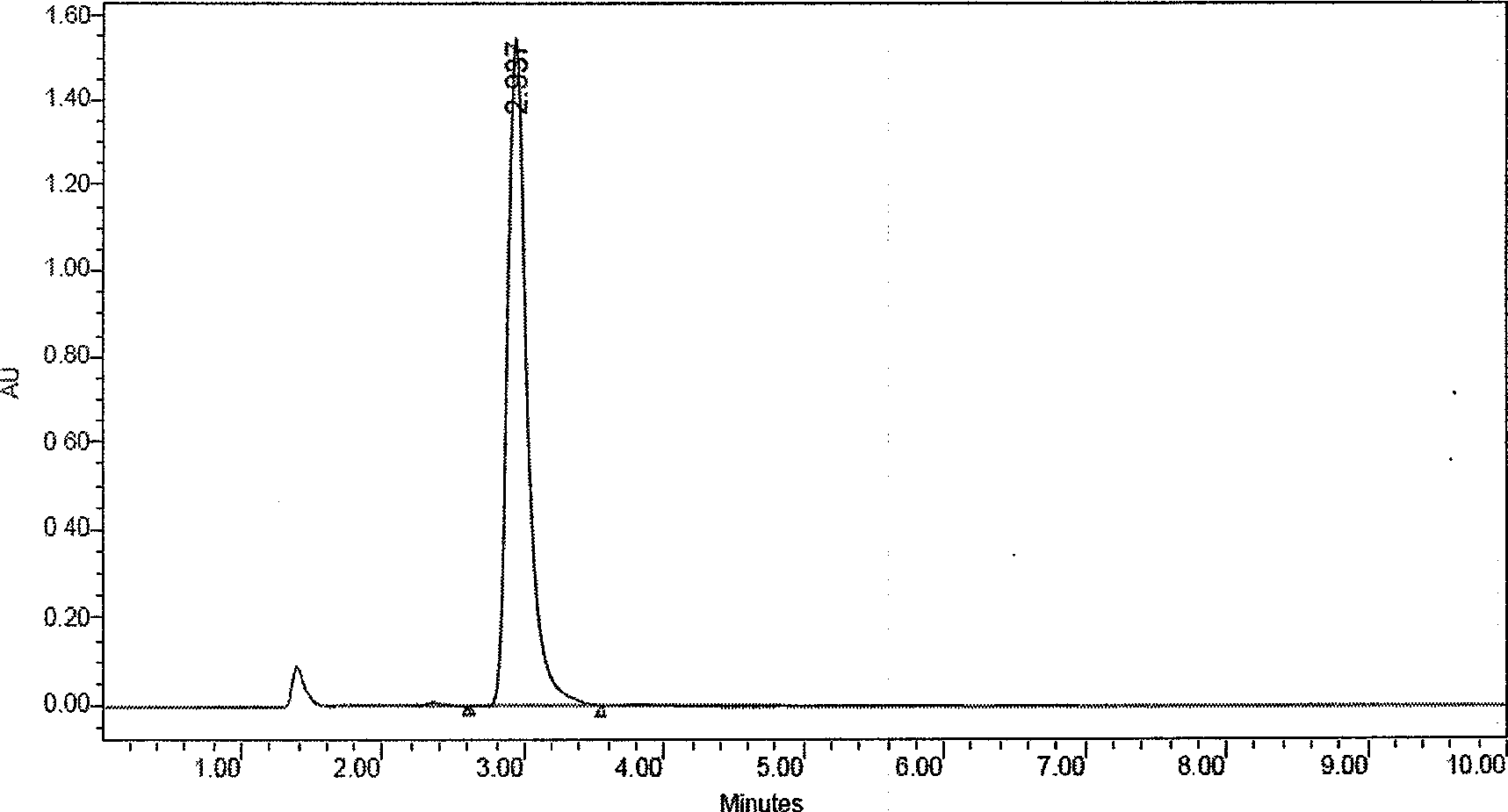

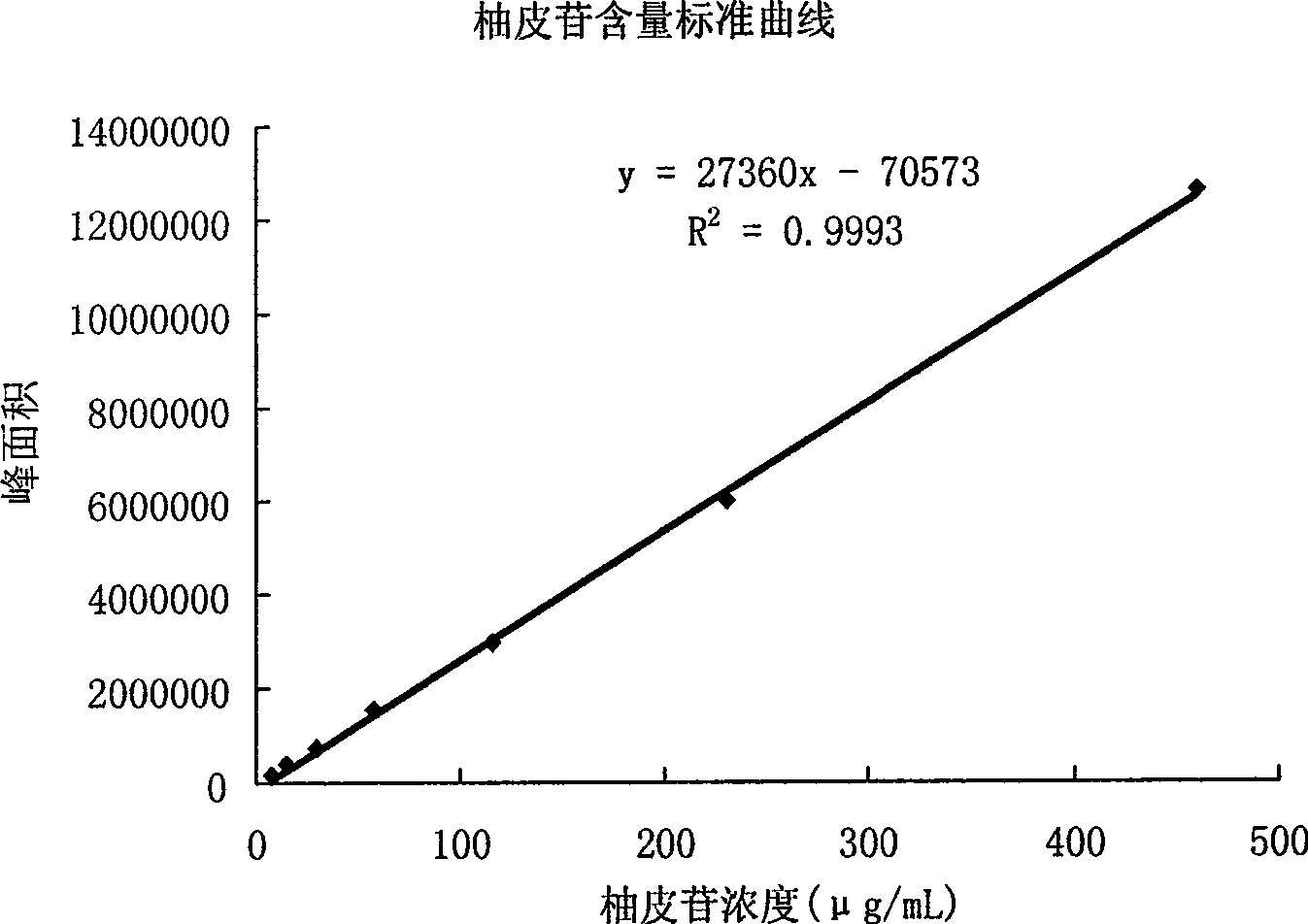

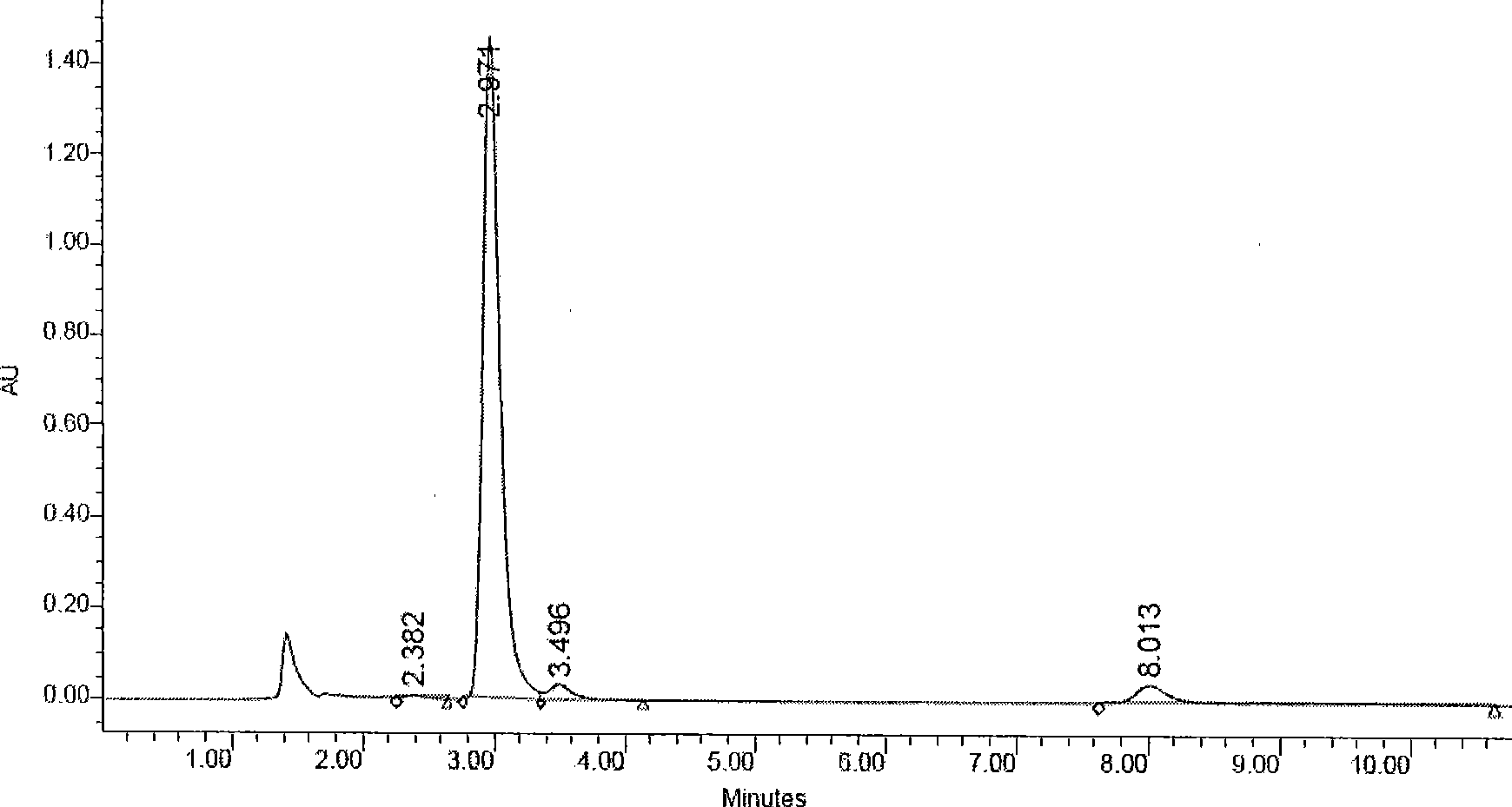

Image

Examples

example 1

[0024] Starch 30g / L, naringin 10g / L, MgSO 4 1g / L, KH 2 PO 4 2g / L, CaCl 2 0.15g / L, (NH 4 ) 2 SO 4 10g / L, ZnSO 4 ·7H 2 O 0.1g / L, yeast extract 6g / L, bean cake powder 10g / L, pH 6.0.

example 2

[0026] Starch 20g / L, naringin 2g / L, MgSO 4 0.2g / L, KH 2 PO 4 0.5g / L, CaCl 2 0.05g / L, (NH 4 ) 2 SO 4 2g / L, ZnSO 4 ·7H 2 O 0.03g / L, yeast extract 0.5g / L, bean cake powder 0.5g / L, pH 6.0.

example 3

[0028] Starch 25g / L, naringin 6g / L, MgSO 4 0.6g / L, KH 2 PO 4 1.3g / L, CaCl 2 0.1g / L, (NH 4 ) 2 SO 4 6g / L, ZnSO 4 ·7H 2 O 0.07g / L, yeast extract 3.3g / L, bean cake powder 6g / L, pH 6.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com