Buffering mechanism for product production line

A buffer device and assembly line technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reducing equipment service life, product production interruption, production volume reduction, etc., to prolong service life, avoid frequent start-up, and increase profit margins Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

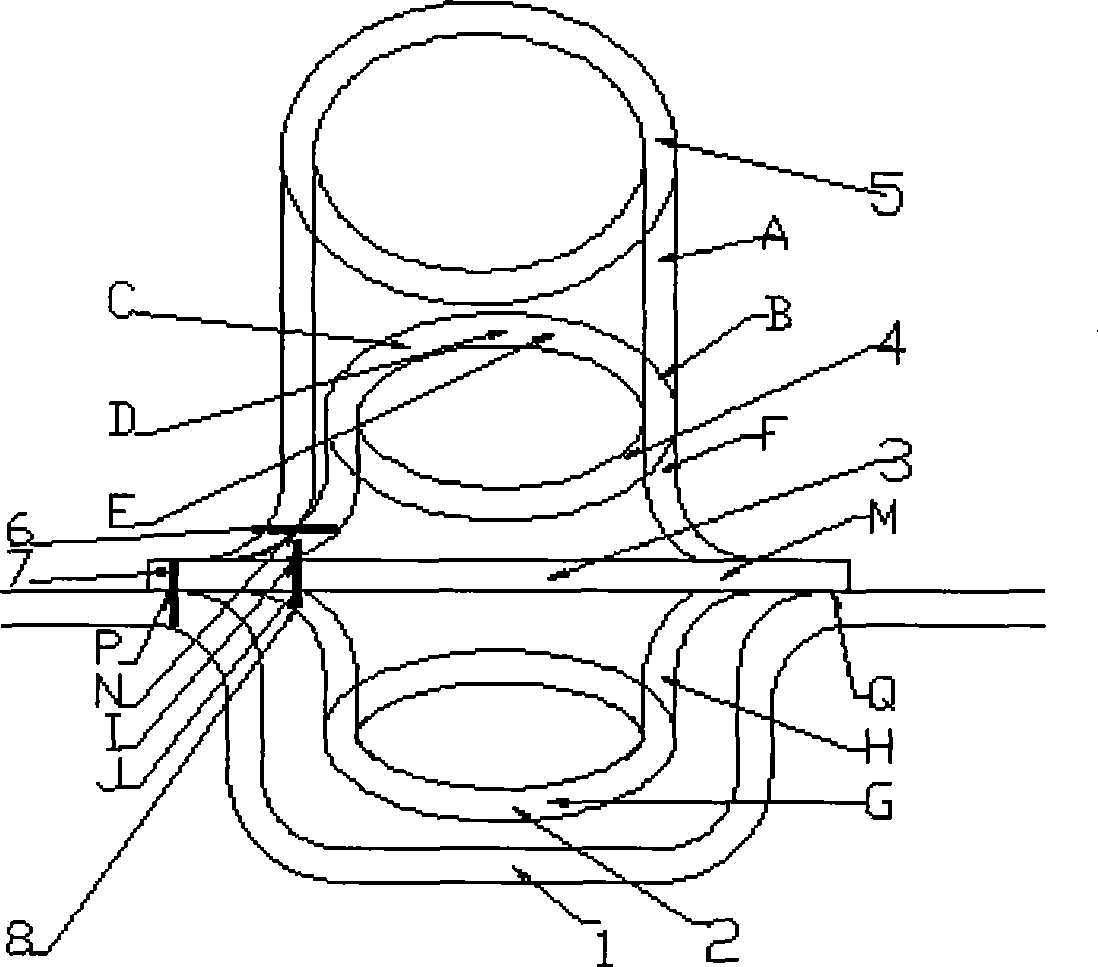

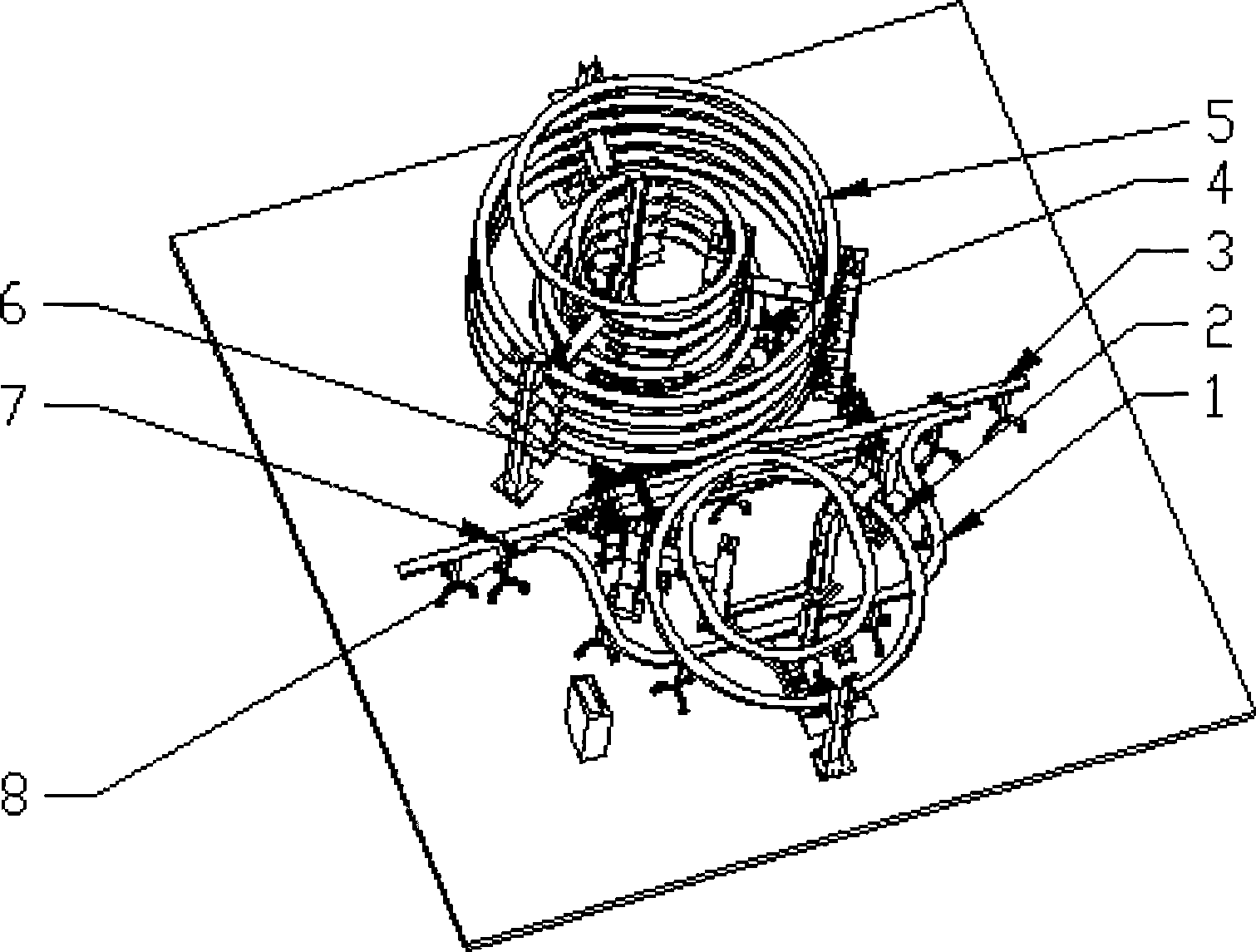

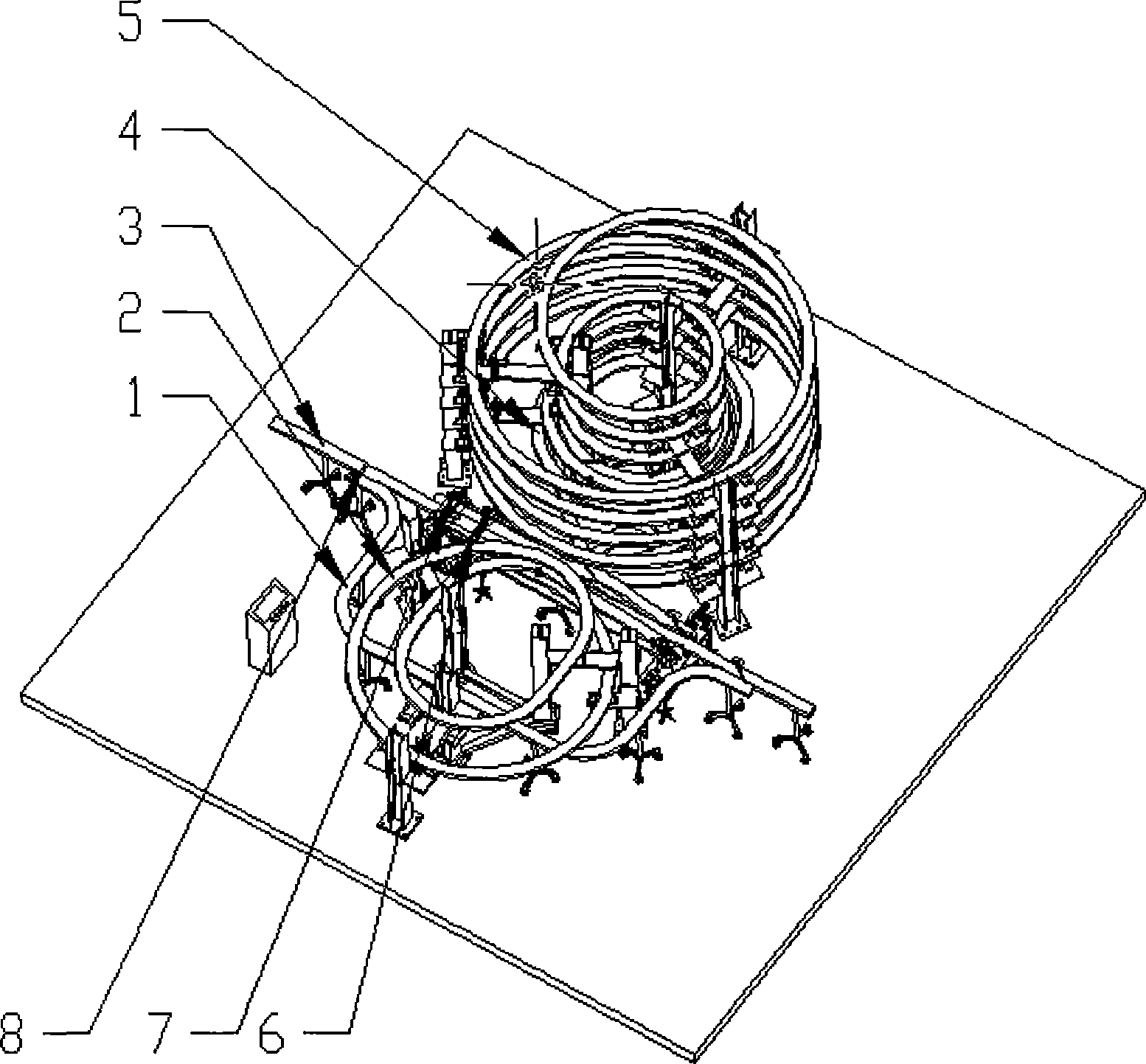

[0015] figure 1 is the plane schematic diagram of the buffer device, and Figure 2 is a three-dimensional view of the buffer device

[0016] see figure 1 2 and the buffer device of the product pipeline of the present invention, the second temporary storage device 3 is at points P and Q with the main circuit 1, at points J and M with the first temporary storage device 2, and at points J and M with the third temporary storage device 4, respectively. Points I and M are connected; the fourth temporary storage device 5 is connected with the third temporary storage device 4 at points N and B; The device that changes product direction, the second conversion device 7 is positioned at I, J point and acts on the device that changes product direction of first temporary storage device 2, second temporary storage device 3 and the 3rd temporary storage device 4, the 3rd conversion device 8 is located at point N and acts on the device for changing the product direction of the third temporar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com