Three segment type heat exchanger

A technology of heat exchanger and subcooling section, which is applied in the field of water-side 3-stage heat exchanger, which can solve the problems of low condensing pressure, limited installation space, and large adjustment range of water flow, so as to achieve small changes in condensing pressure and improve Condensation conditions, the effect of increasing the COP value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The specific implementation, non-limiting examples are as follows:

Embodiment

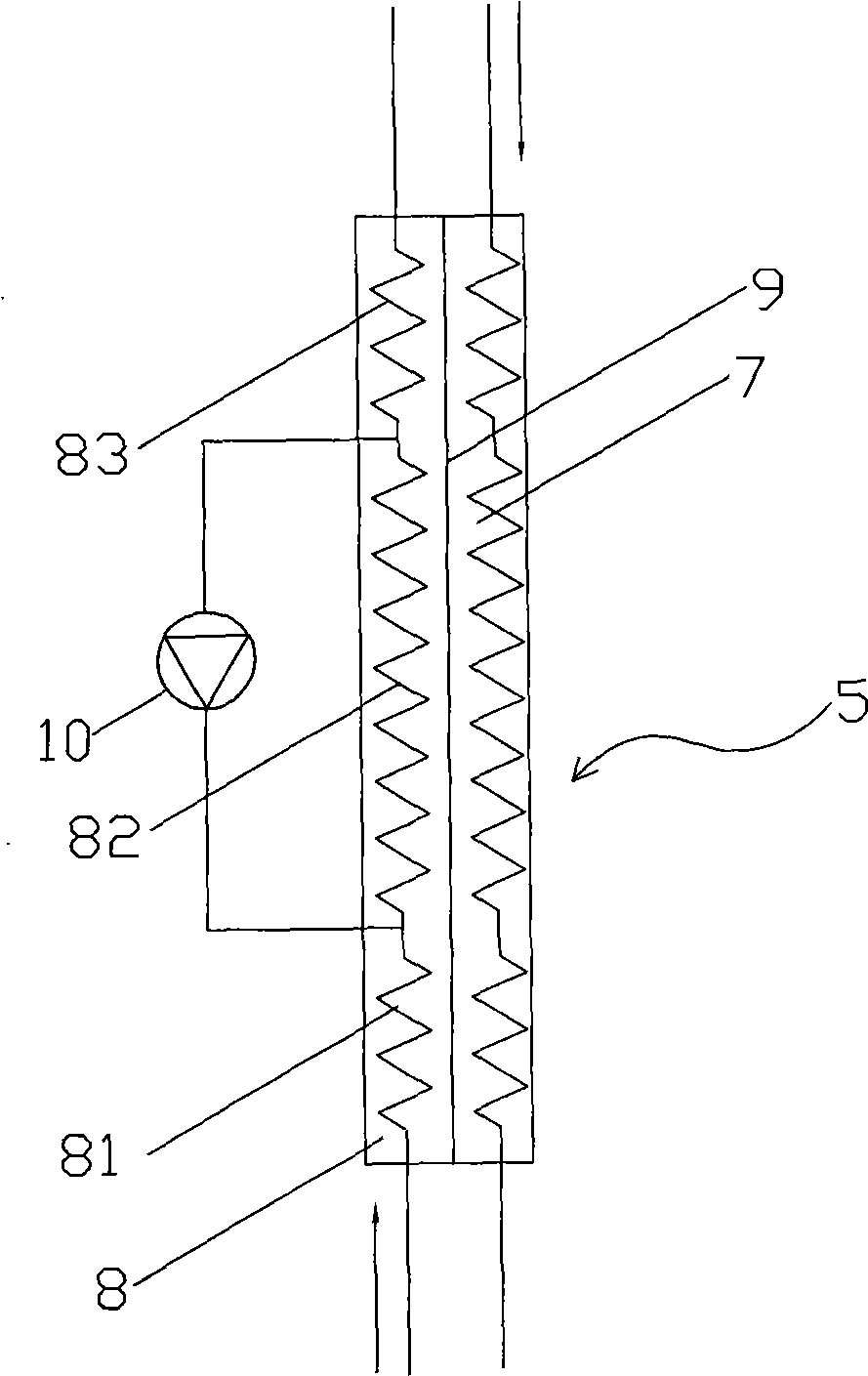

[0025] Example: figure 1 As shown, the 3-stage heat exchanger has a freon flow channel 7 and a water flow channel 8, and the two flow channels have a common flow channel wall 9, and the media in the freon flow channel 7 and the water flow channel 8 flow in opposite directions to each other in the common The flow channel wall 9 completes the heat exchange, and the water flow channel is divided into a subcooling section 81, a saturation section 82 and a superheating section 83 in series from the inlet end to the outlet end, in order to increase the water circulation in the saturation section when necessary without changing The total amount of water in and out of the water channel is connected in parallel with a circulating water pump 10 on the saturated section 82. The inlet and outlet of the circulating water pump 10 are connected to the outlet and the inlet of the saturated section 82 respectively. Decide.

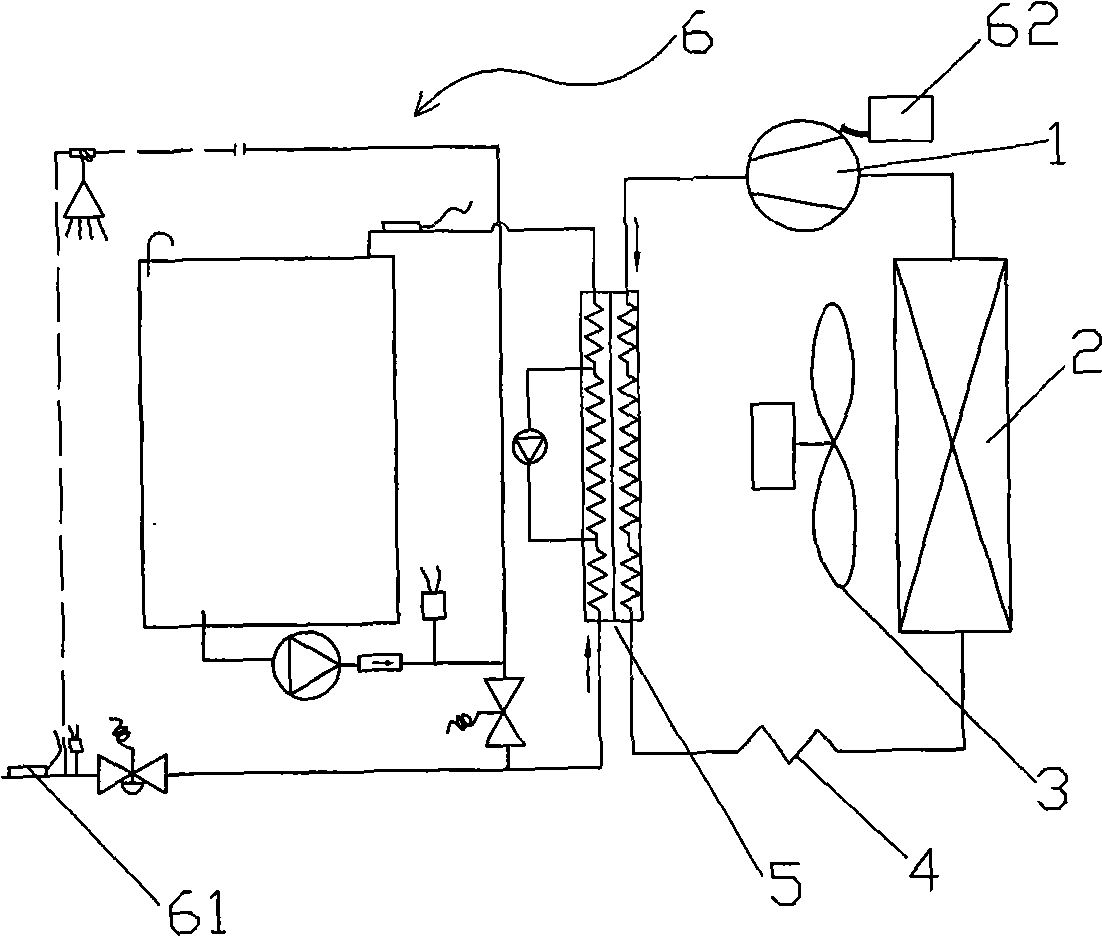

[0026] figure 2 As shown, the unit in this embodiment includes: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com