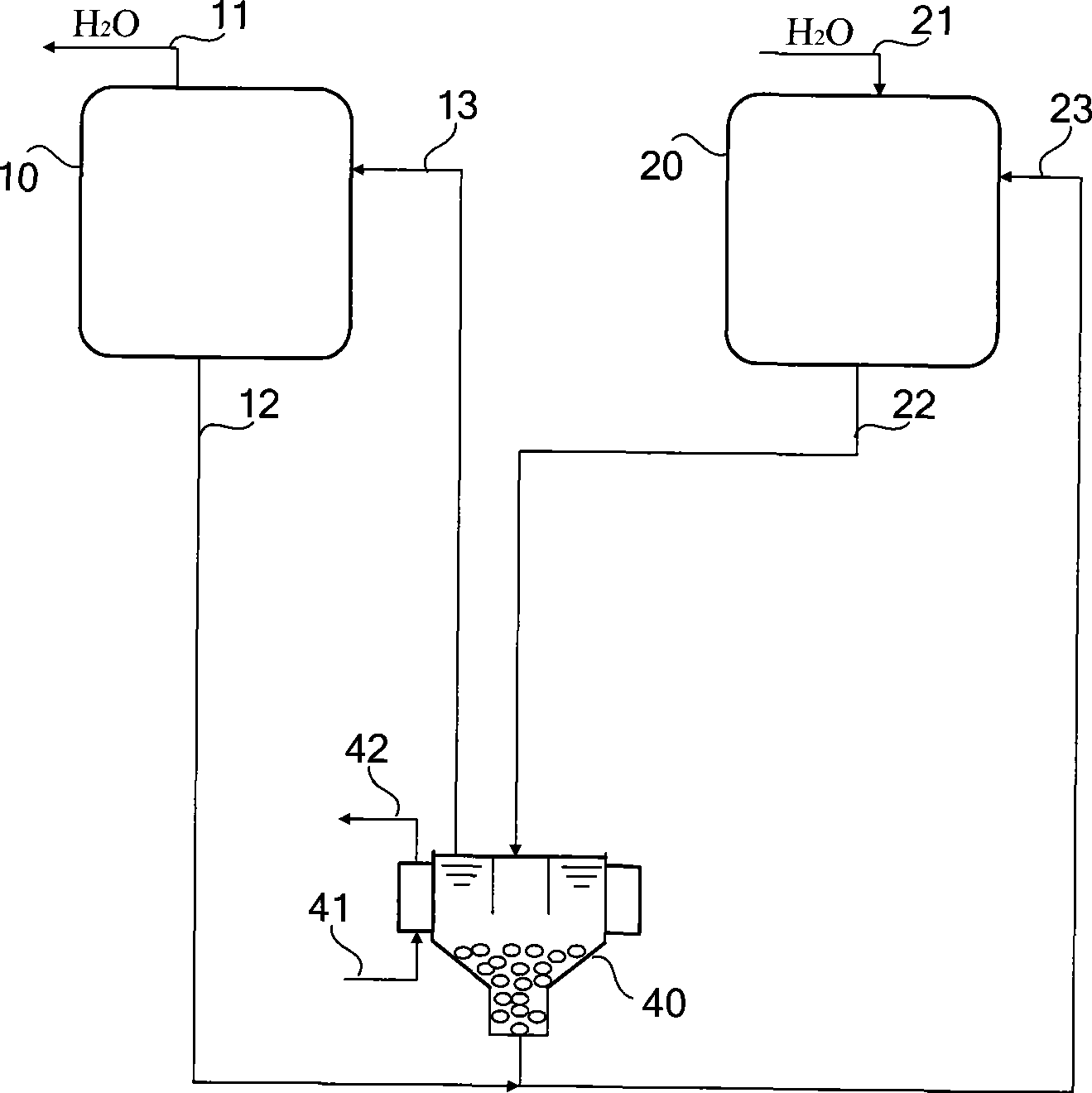

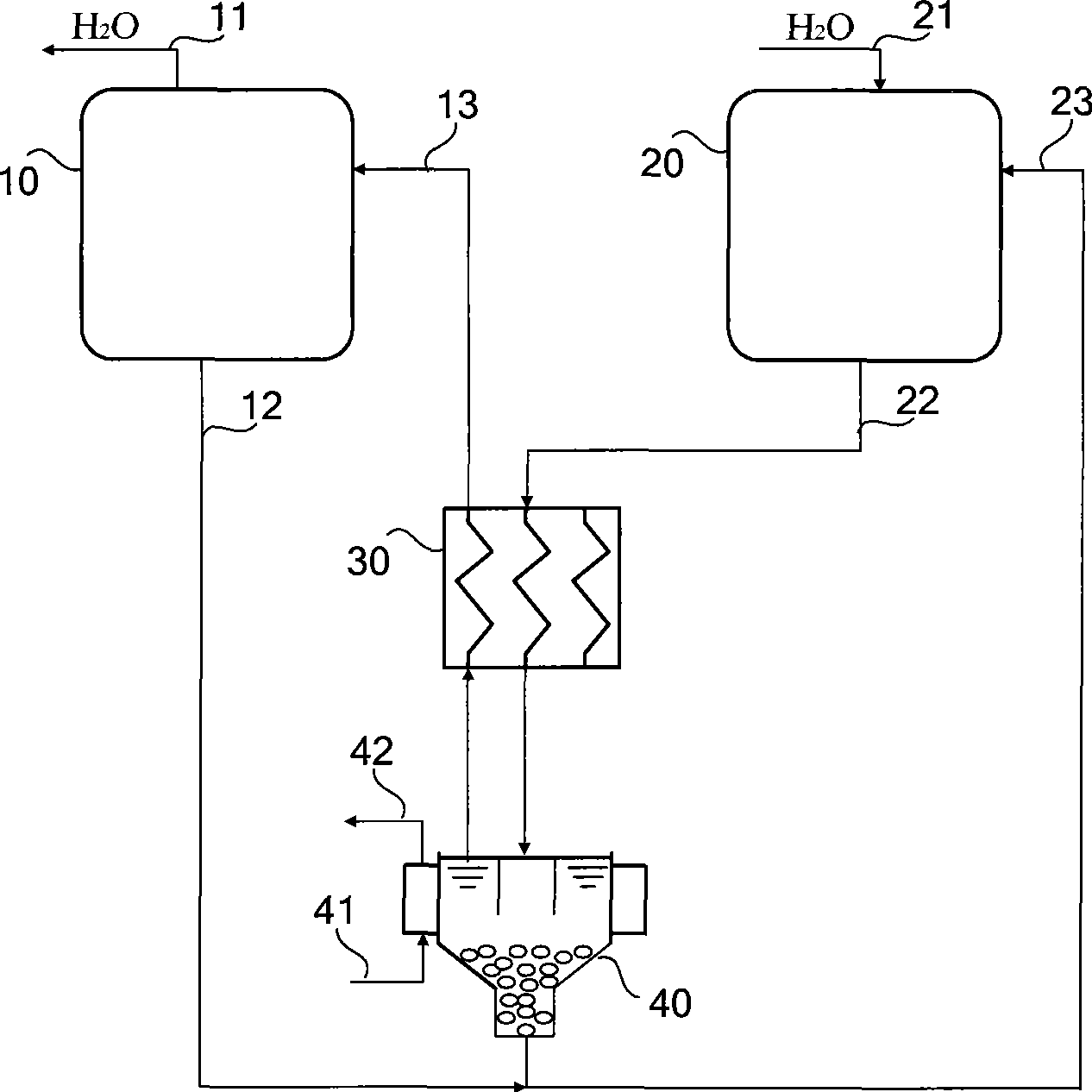

Absorbent solution circulating system and method

A technology for absorbing solutions and circulation systems, applied in the direction of adsorption machines, refrigeration and liquefaction, climate change adaptation, etc., to achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] In this example, the low-temperature waste heat at 100°C is elevated to saturated steam at a temperature of 185°C. This example uses 32°C cooling water to cool the condenser and absorbent crystallizer.

example 2

[0063] In this example, the low-temperature waste heat at 75°C is elevated to saturated steam at a temperature of 150°C. This example uses 17°C cooling water to cool the condenser and absorbent crystallizer.

example 3

[0065] In this example, the low-temperature waste heat of 90°C is raised to saturated steam with a temperature of 170°C. In this example, the cooling water at 32°C is used to cool the condenser, and the cold generated by the vapor compression refrigeration cycle is used to cool the absorbent crystallizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com