Non-warp non-crack floor

A crack-free, floor-free technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of noise, easy damage, and difficult to close solid wood floors, and achieves the effect of saving fabrics, reducing thickness, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

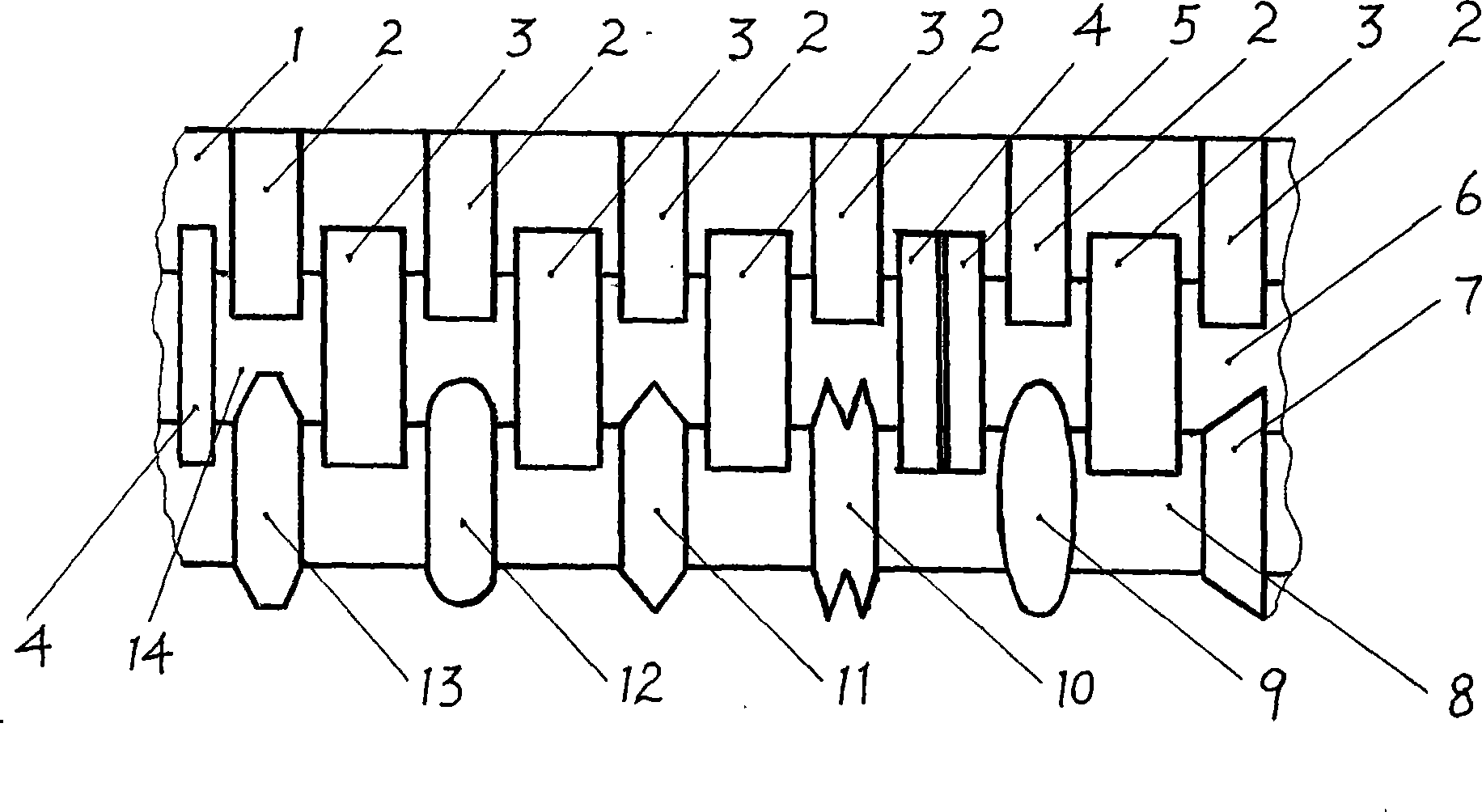

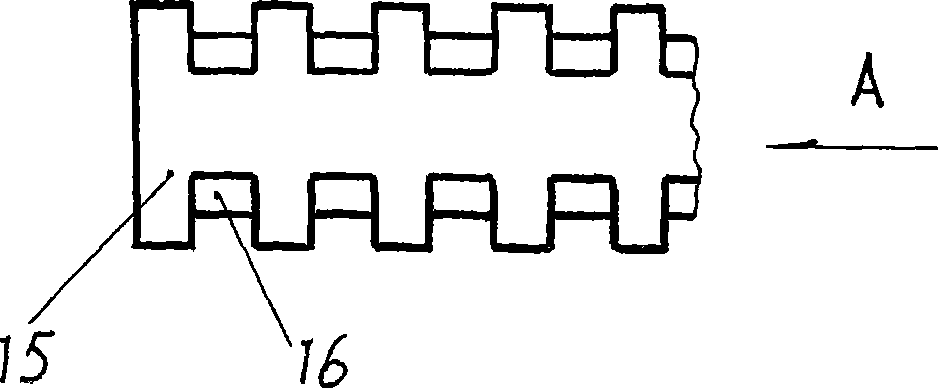

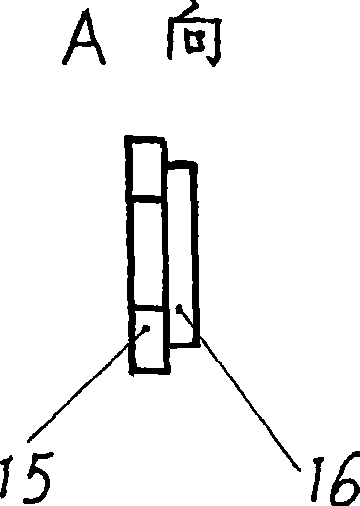

[0012] refer to figure 1 , a medium-sized anti-warping fixing plate [2] is installed on the bottom surface of the solid wood floor A[1]. The other end of the medium-sized anti-warping fixed plate [2] exposes the part outside the inner side edge of the solid wood floor A [1] and is respectively close to the bottom surface of the solid wood floor B [6] and the solid wood floor D [14].

[0013] A large anti-warping fixing plate [3] is installed on the bottom surface of the solid wood floor B[6], a small anti-warping fixing plate B[5] is installed on the bottom surface of the end surface, the large anti-warping fixing plate [3] and the small anti-warping fixing plate The two ends of the fixing plate B[5] expose the parts outside the edge of the solid wood floor B[6] and are respectively attached to the bottom surface of the solid wood floor A[1] and the solid wood floor C[8].

[0014] The bottom surface of the solid wood floor D[14] is equipped with a large anti-warping fixed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com