Coiling apparatus for warp knitting machine fabric

A technology of coiling device and warp knitting machine, which is applied in warp knitting, knitting, textiles and papermaking, etc. It can solve the problems of reduced fabric elasticity, small fabric tension adjustment range, and unstable sliding fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

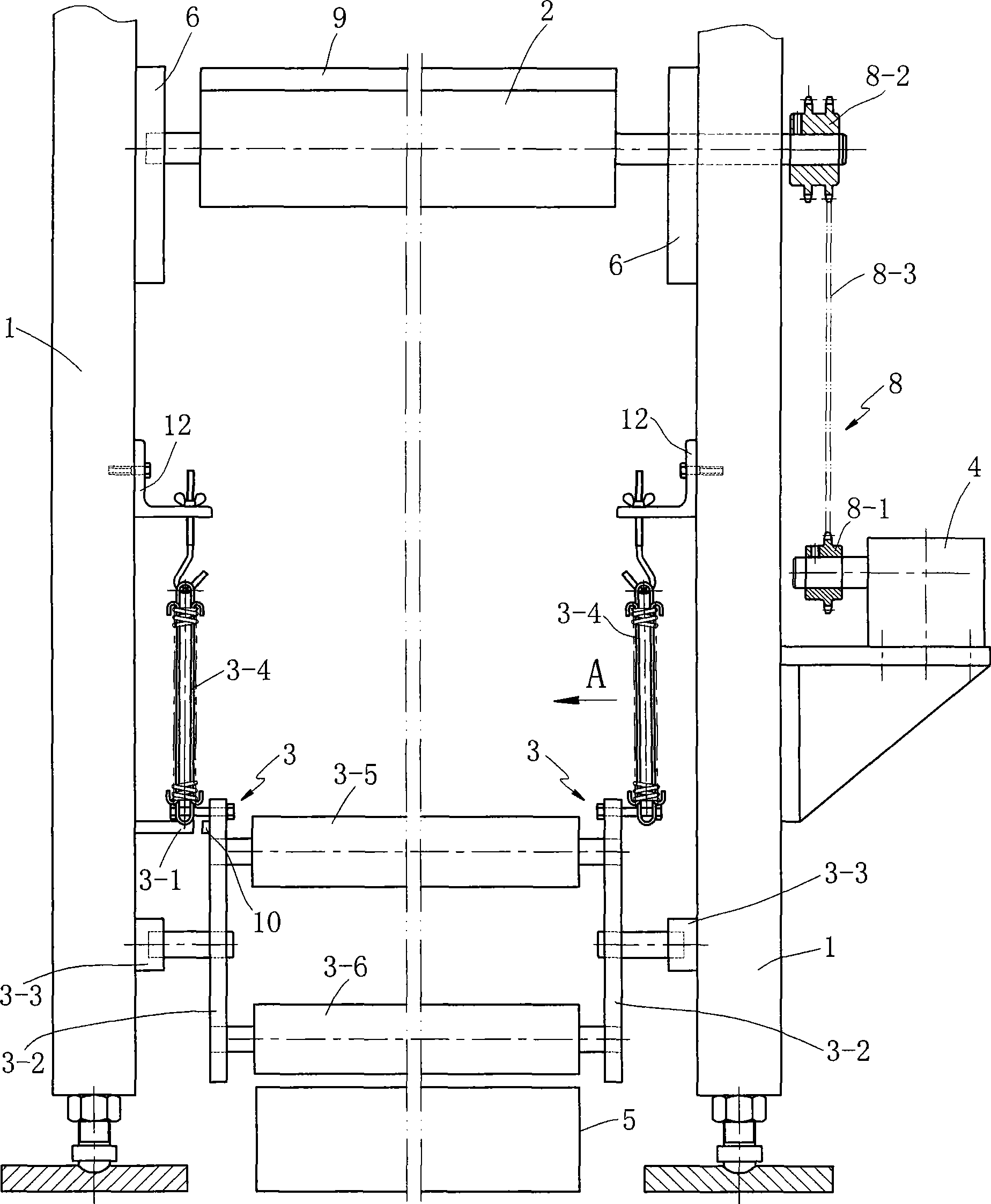

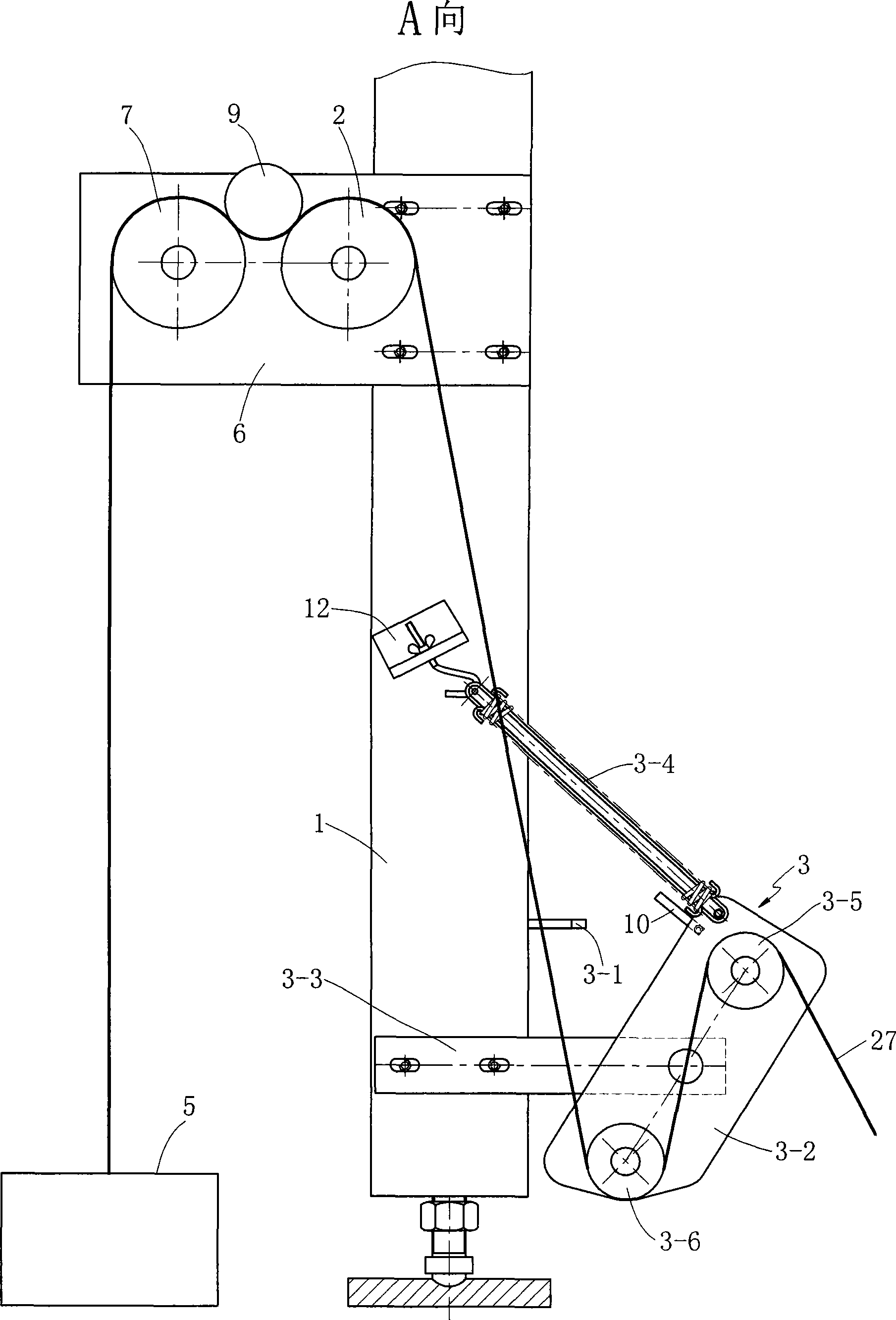

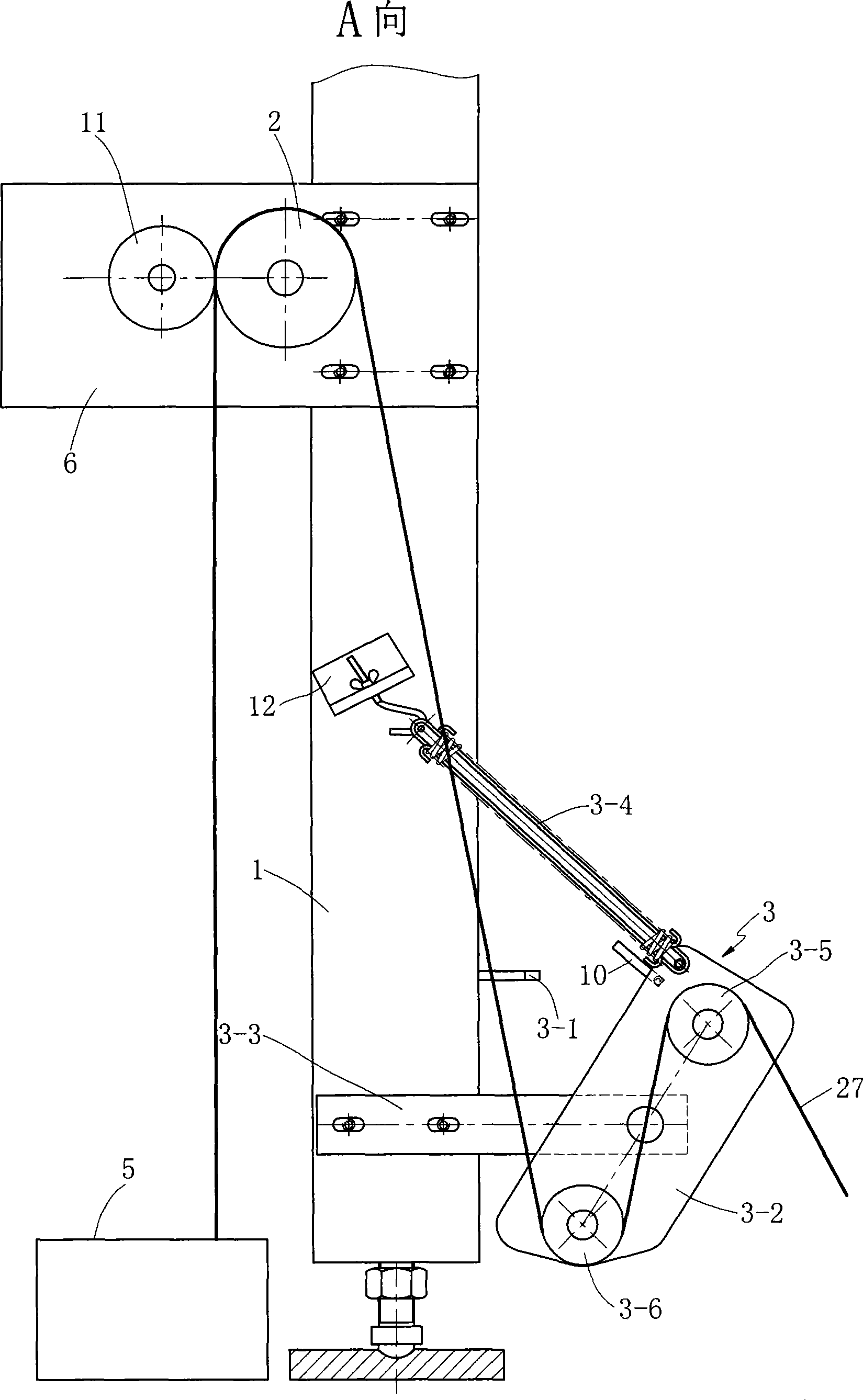

[0017] see Figure 1 to Figure 3Shown is a winding device suitable for warp knitting fabrics, which includes a first cloth roll 2 and a fabric tension adjustment mechanism 3 that are rotatably installed on the warp knitting machine frame 1, and the first cloth roll 2. Driven by a driving device 4, the present invention adopts a motor to rotate, and the fabric tension adjustment mechanism 3 includes a cloth guide roller mounting seat 3-2, a connecting plate 3-3, and a threaded connection that are respectively located on both lateral sides of the frame 1. The auxiliary adjustable tension spring 3-4, the first cloth guide roller 3-5 and the second cloth guide roller 3-5 which are arranged between the cloth guide roller mounting bases 3-2 and which are rotationally connected with the bearings with seats or ordinary ball bearings The roller 3-6, and the sensor 3-1 arranged on the frame 1 and electrically connected to the sensor 3-1 and after obtaining its output signal, turn on or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com