Railway track-mounted machinery

A technology of railway tracks and machinery, applied in the direction of wheel axle self-adjustment, etc., can solve the problems of car body deflection, difficulty in standing for construction personnel, and instability of workpiece placement, and achieve the effect of eliminating car body deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

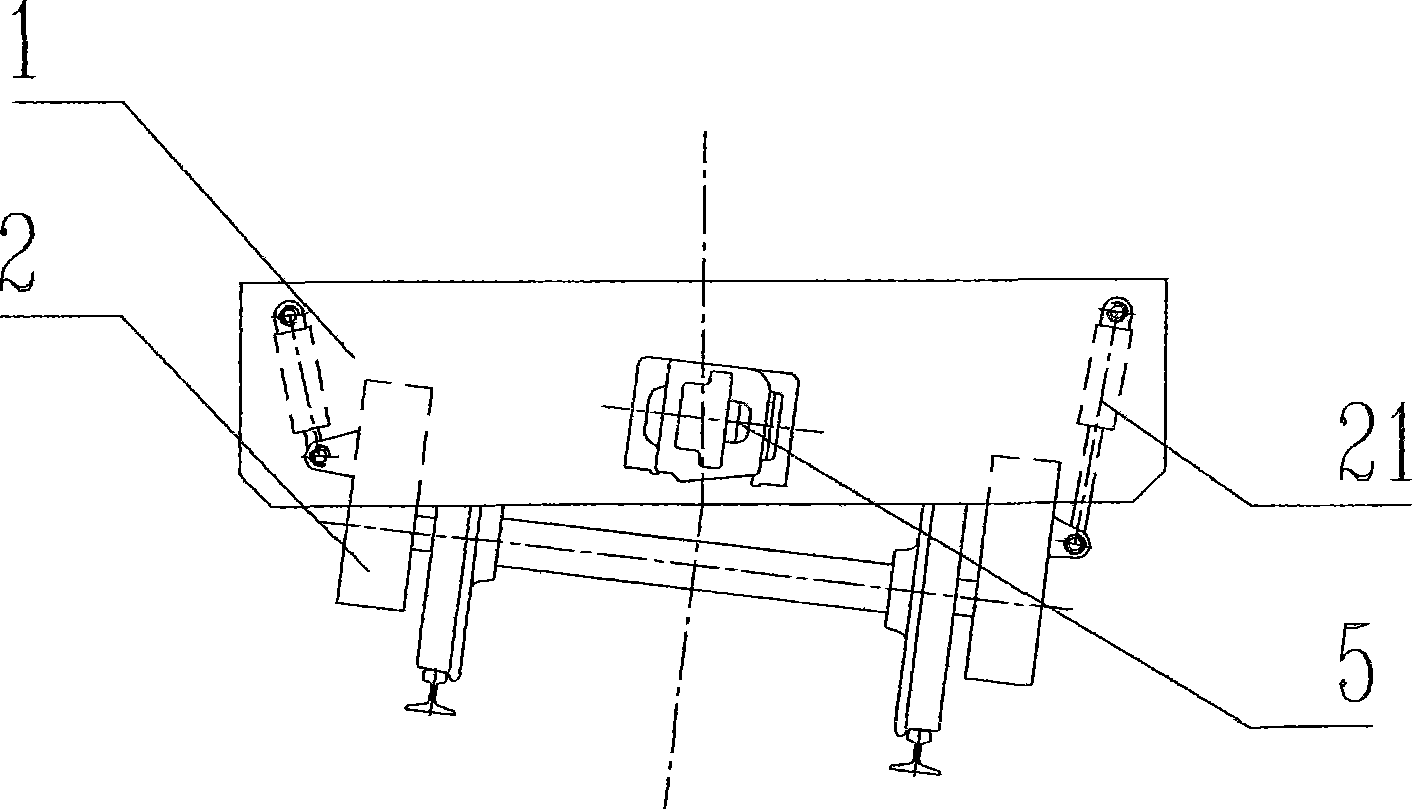

[0022] figure 1 Among them, (1) is the main frame, (2) is the bogie, (21) is the leveling mechanism, and (5) is the coupler. Now the main frame (1) remains on the inclined position together with the bogie (2), and the vehicle coupler (5) also remains on the inclined position.

[0023] figure 2 At this time, the main frame (1) is adjusted to the horizontal position through the leveling mechanism (21), while the bogie (2) is still kept in the tilted position, and the coupler (5) is also kept in the tilted position. The leveling mechanism (21) is a hydraulic drive mechanism.

[0024] image 3 Among them, (1) is the main frame, (2) is the bogie, (6) is the center pin, (7) is the elastic lower side bearing, (8) is the spherical bearing, (9) is the equalizing beam, (10) For rotating shaft, (11) is working cylinder, and working cylinder can adopt hydraulic cylinder or air cylinder, and (12) is mechanical locking device, and (13) is wheel pair, and (14) is steel rail. The bogie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com