Mounting and demounting method roof plate formwork support platform of concrete silo

A formwork support and platform support technology, applied in formwork/formwork/work frame, house structure support, house structure support, etc., can solve the problems of complex construction process, low construction efficiency, long construction period, etc., to simplify the construction process , The effect of reducing the difficulty of construction and reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

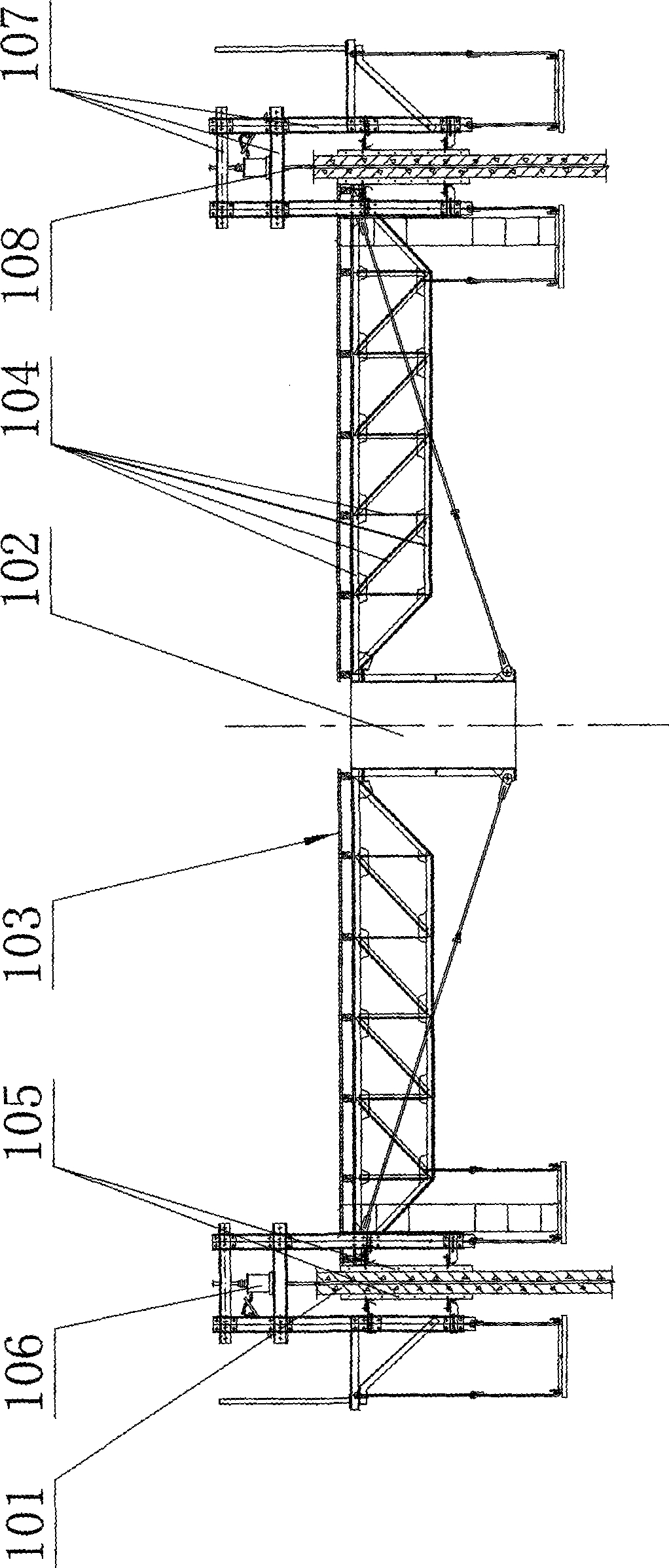

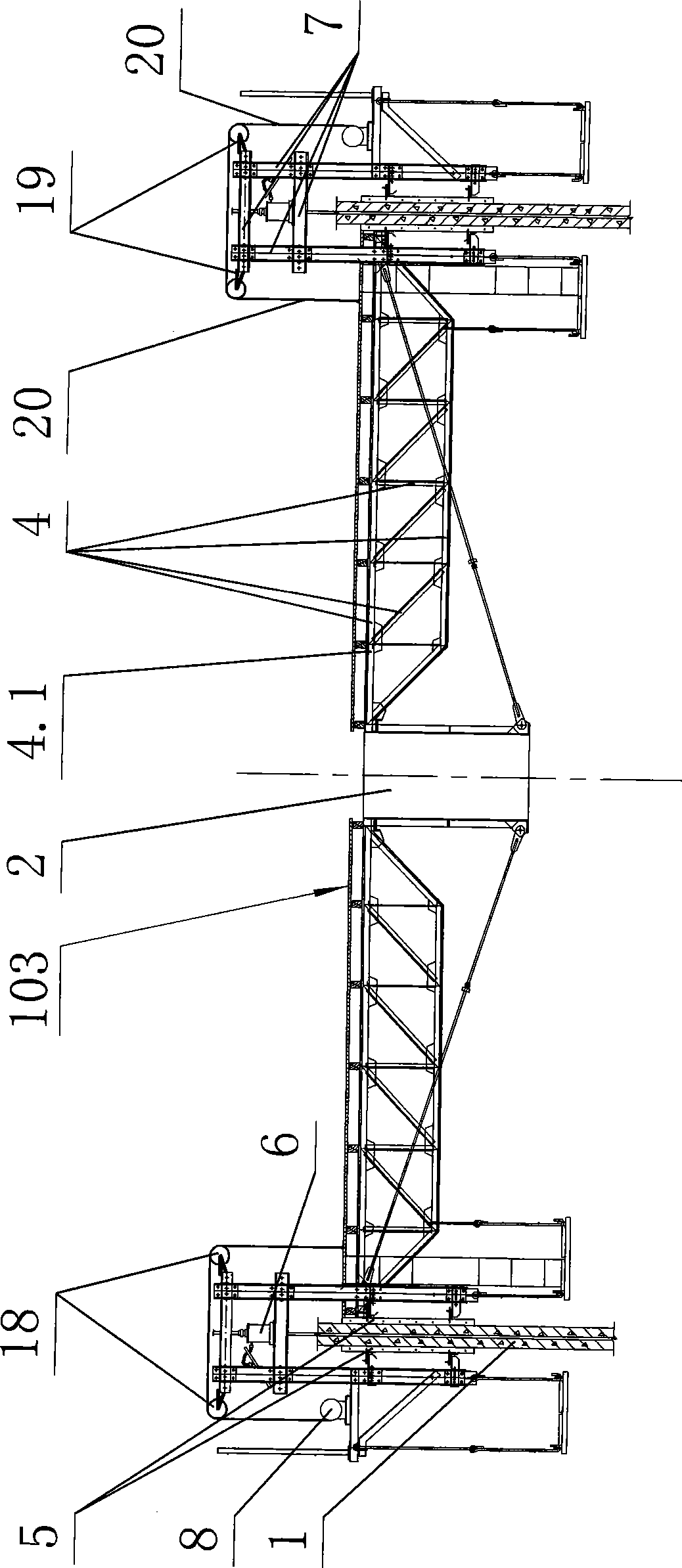

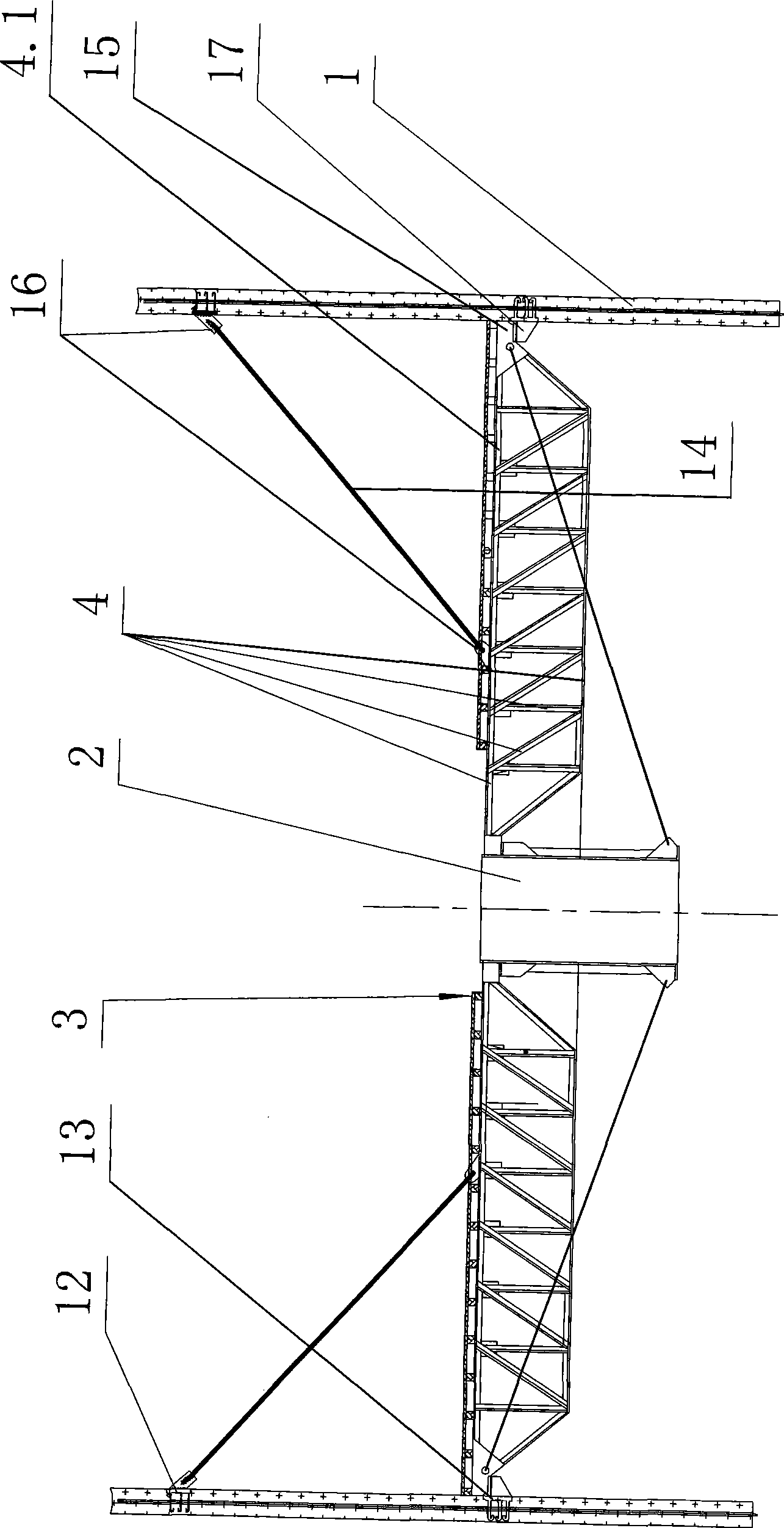

[0043] Such as figure 2 , image 3 , Figure 4 , Figure 5 Shown, the installation and dismounting method of the roof formwork support platform of concrete silo of the present invention, it comprises following construction steps:

[0044] a. During the construction of the sliding form, multiple sets of embedded parts are set on the cylinder wall 1 (that is, 101 in the prior art, which is remarked to distinguish it from the prior art, and the following 102, 104, 105, 106, and 107 are the same), namely Each group of embedded parts includes an upper embedded steel part 12 and a lower embedded steel part 13, and the number of groups of embedded parts is equal to the upper chord 4.1 of the steel truss 4 (ie 104 in the prior art) on the construction platform 103 Each lower embedded steel piece 13 corresponds to one end position of each upper cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com