Prefabricated house

A technology for housing and prefabricated parts, applied in construction, building construction, etc., can solve problems such as difficulty in general use, no prestress tensioning, and inability to manufacture workshops for batch standardized production reserves, so as to enhance the load bearing capacity and avoid unfavorable factors. and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Referring to the drawings, the prefabricated houses are assembled according to the following steps:

[0023] 1. Basic assembly method:

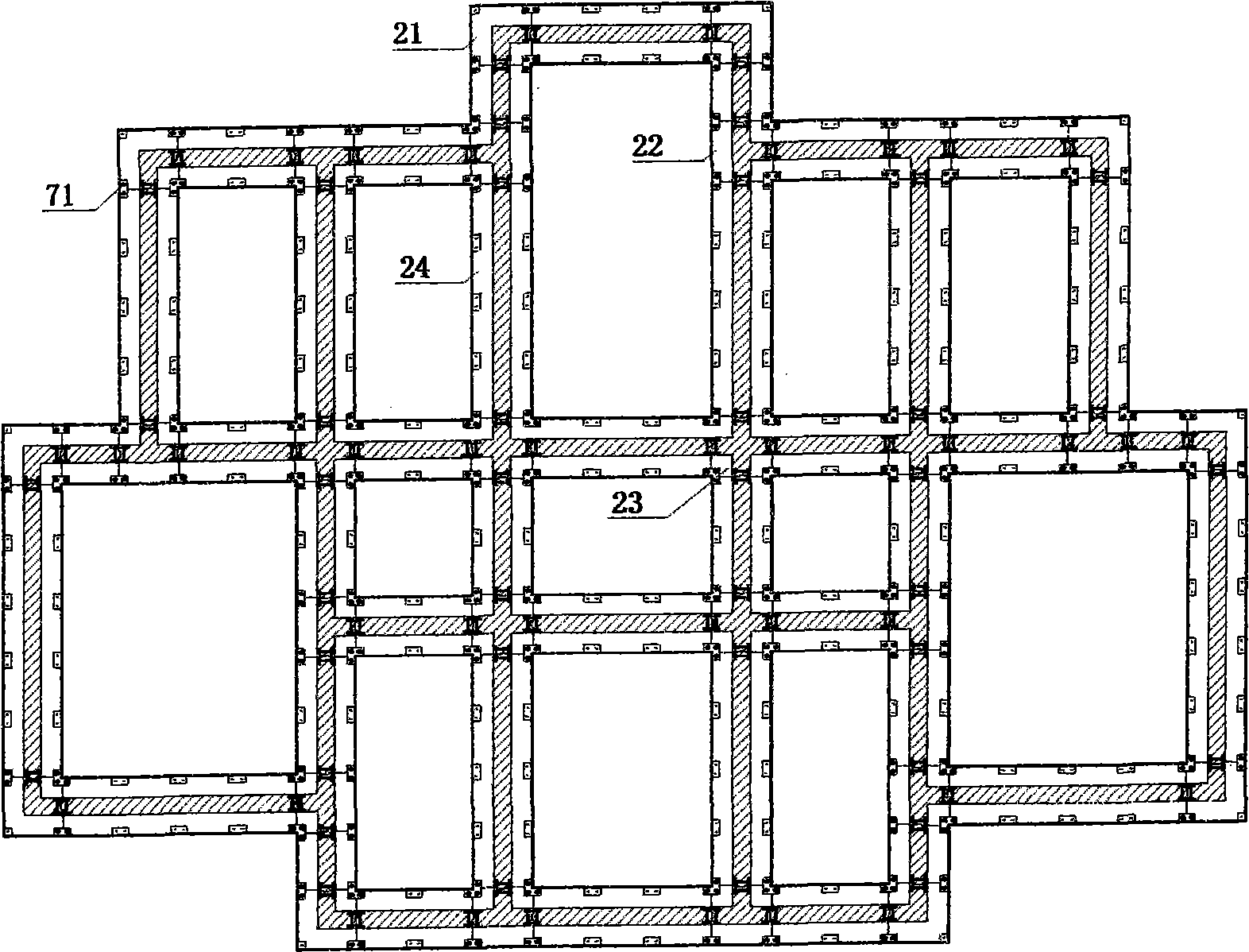

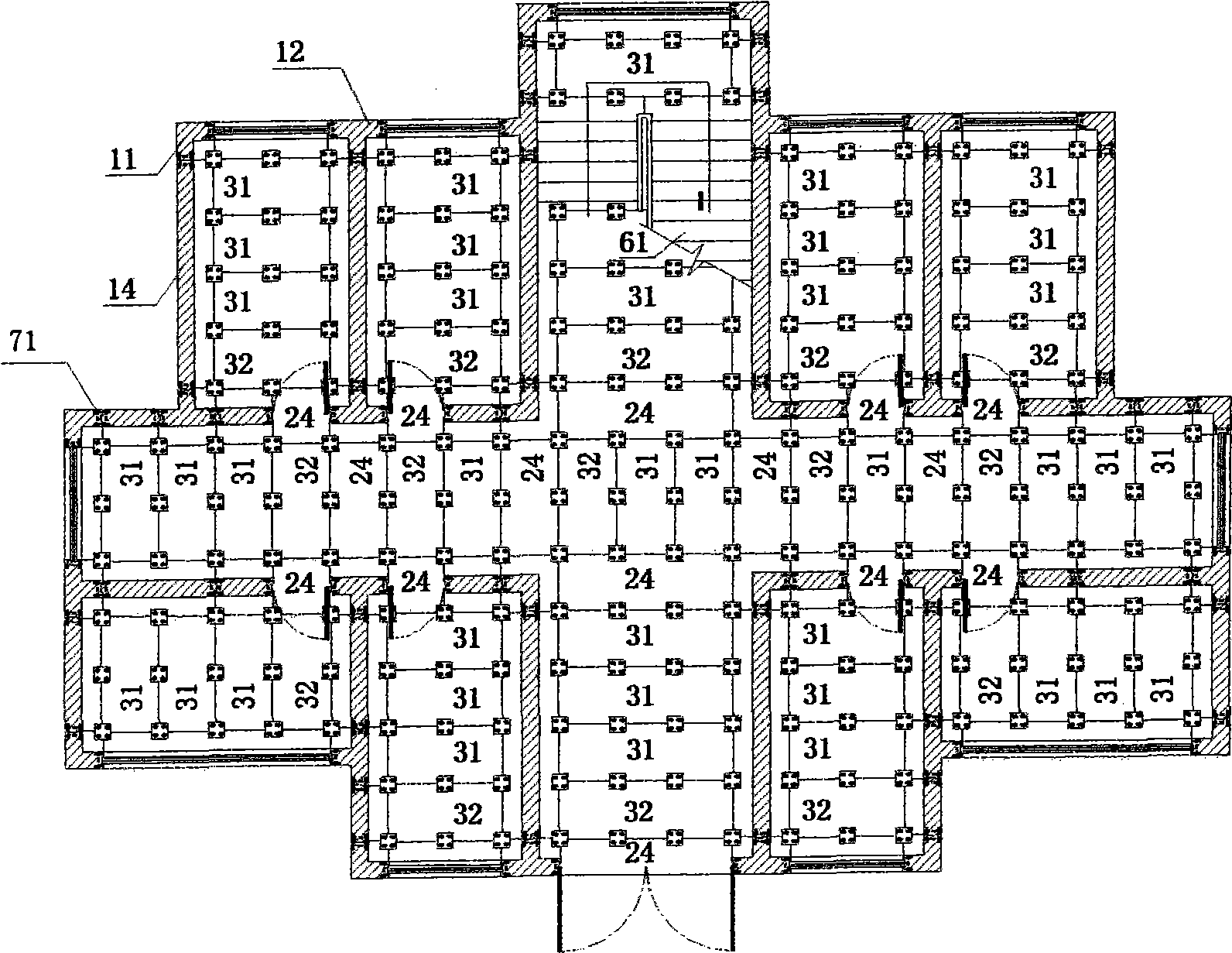

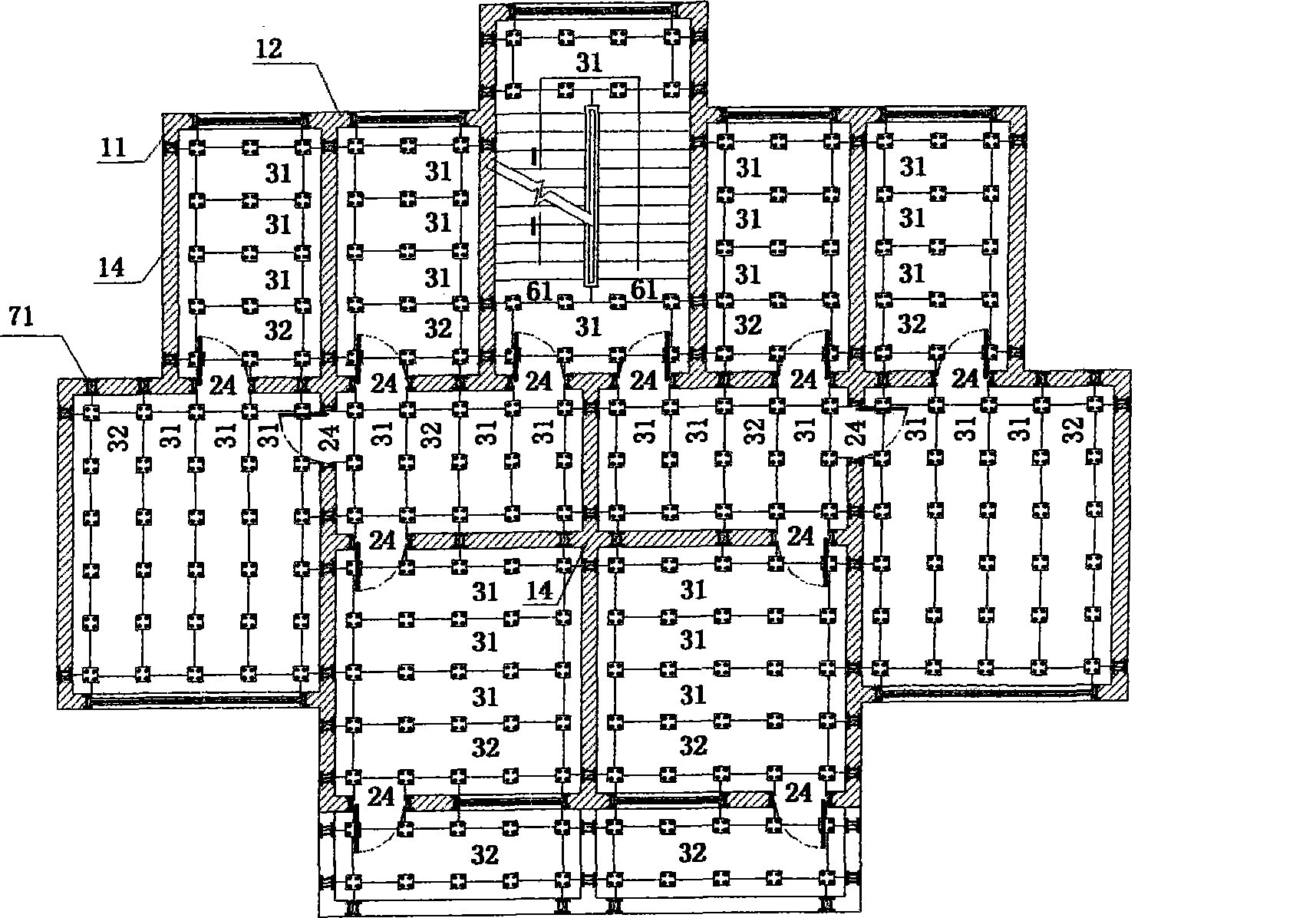

[0024] (1), strip foundation: the beam prefabricated type prefabricated part (21) as wall (column) plate prefabricated part Type Prefabs (11) type foundation; the beam prefabricated type prefabricated part (22) as wall (column) plate prefabricated part Type Prefabs (12) type foundation; use the "+" type prefabricated part (23) in the beam prefabricated part as the "+" type foundation of the "+" type prefabricated part (13) in the wall (column) plate prefabricated part; use the "+" type foundation in the beam prefabricated part The "—" type prefabricated part (24) is used as the "—" type foundation of the "—" type prefabricated part (14) in the wall surface (column) plate prefabricated part. In this way, the bar-shaped foundation of the house is assembled by connecting the corresponding prefabricated parts between the beam p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com