Rigid gridding and pile combined foundation and its use in soft soil foundation reinforcement

A technology of composite foundation and soft soil foundation, applied in the fields of railway engineering, port engineering, construction engineering and highway engineering, can solve the problems of limited depth of reinforced soft soil foundation, unable to meet the requirements of foundation reinforcement, limited strength and deformation performance, etc. Improve the quality of design and construction, facilitate design calculation and analysis, and improve the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

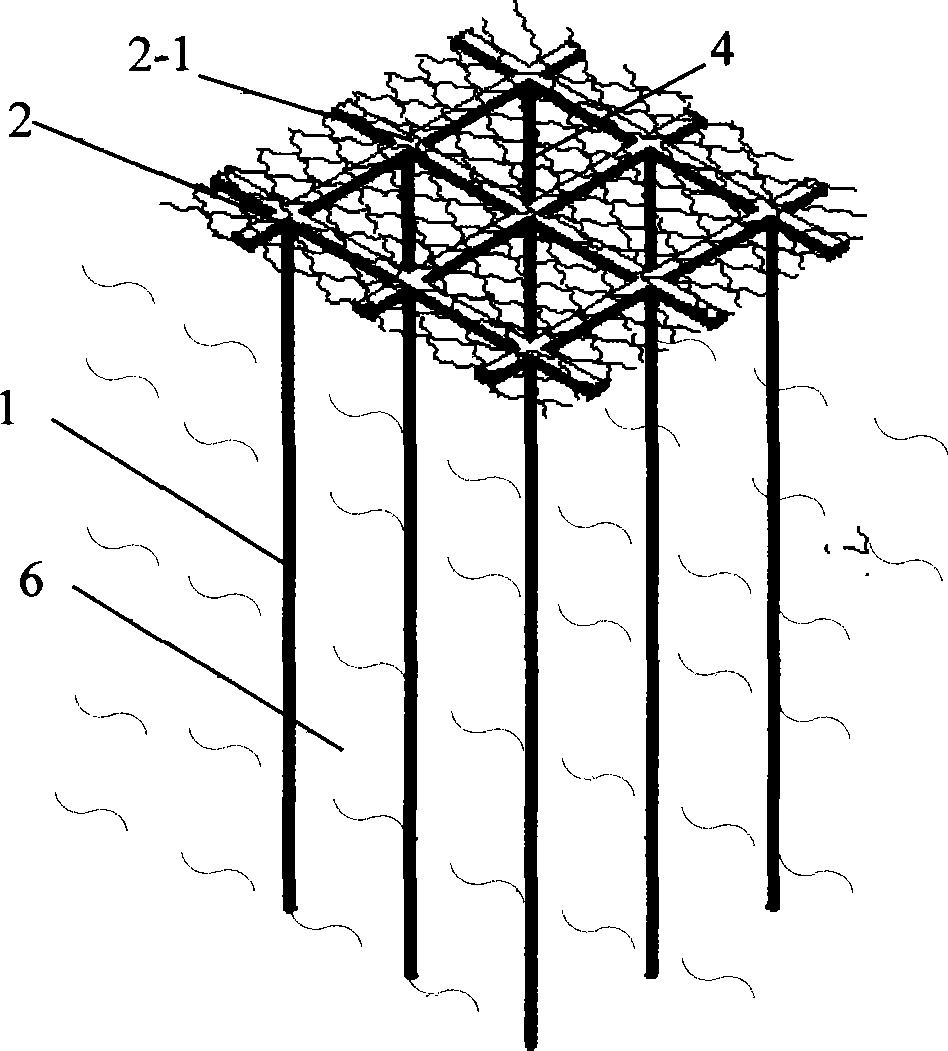

[0049] like figure 1 As shown, the rigid grid and pile composite foundation is composed of prefabricated pile 1, rigid grid structure 2, tension net 4 and transition cushion 5. The prefabricated piles pass through the soft soil layer 6, and are driven from the foundation surface to the relatively hard soil layer 7. The distance between the prefabricated piles is 0.6m, and the cross-sectional size of the prefabricated square piles is 0.08m×0.08m. The top of the prefabricated pile is fixedly connected to the node 2-1 of the rigid grid. The tension net is laid on the rigid grid structure, and a 0.6m thick gravel soil transition cushion is laid on the tension net. A grid 8 is arranged in the transition cushion. The fill soil 9 is filled on the transition cushion to form a subgrade project reinforced by a composite foundation of rigid grids and piles.

[0050]The specific construction steps are as follows:

[0051] (1) if image 3 As shown, concrete prefabricated piles are lai...

Embodiment 2

[0056] like figure 1 As shown, the rigid grid and pile composite foundation consists of cast-in-place piles 1, rigid grid structure 2, tension bars 3, tension nets 4 and transition cushion 5. The cast-in-place piles pass through the soft soil layer 6 and are driven from the foundation surface to the relatively hard soil layer 7. The distance between the cast-in-place piles is 3.0m, and the cross-section of the cast-in-place piles is circular with a diameter of 0.40m. The top of the cast-in-place pile is fixedly connected to the node 2-1 of the rigid grid. Tension bars are laid on the rigid grid structure. Tension mesh is laid on the tension bars. A 1.0m thick gravel soil transition cushion is laid on the tension net. A grid 8 is arranged in the transition cushion. The fill soil 9 is filled on the transition cushion to form a subgrade project reinforced by a composite foundation of rigid grids and piles.

[0057] The specific construction steps are as follows:

[0058] (1...

Embodiment 3

[0063] like figure 1 As shown, the rigid grid and pile composite foundation is composed of prefabricated pile 1, rigid grid structure 2, tension net 4 and transition cushion 5. The prefabricated piles pass through the soft soil layer 6 and are driven from the surface of the foundation to the relatively hard soil layer 7. The distance between the prefabricated piles is 2.5m. The prefabricated piles are H-section steel piles, the model is 300×300 ("Code for Design of Steel Structures" GB50017 -2003). The top of the prefabricated pile is fixedly connected to the node 2-1 of the rigid grid. The tension net is laid on the rigid grid structure, and a 1.0m thick gravel soil transition cushion is laid on the tension net. A grid 8 is arranged in the transition cushion. The fill soil 9 is filled on the transition cushion to form a subgrade project reinforced by a composite foundation of rigid grids and piles.

[0064] The specific construction steps are as follows:

[0065] (1) if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com