Self-twisting hollow ingot special for jet air vortex spinning

A technology of hollow spindle and vortex spinning, which is applied to spinning machines, textiles and papermaking, and open-end spinning machines, etc. It can solve the problems of many details, low strength, and poor yarn structure, so as to reduce loss and increase strength , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

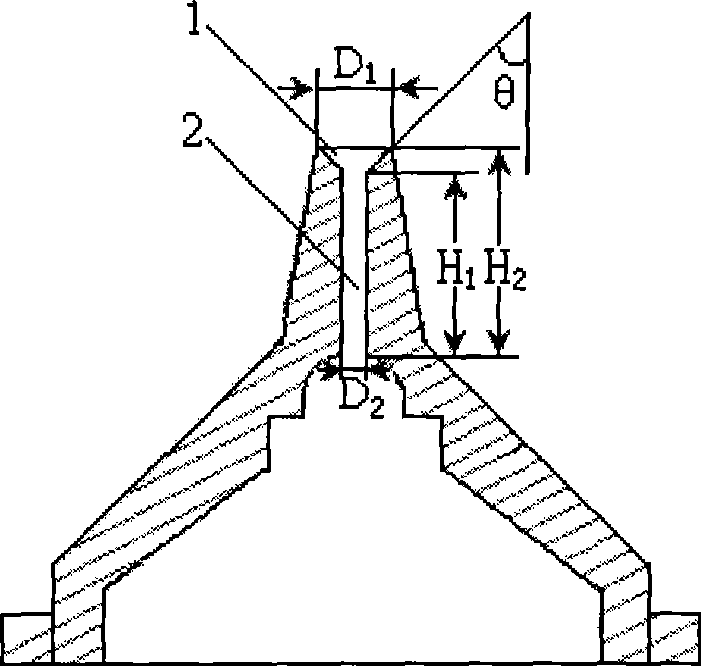

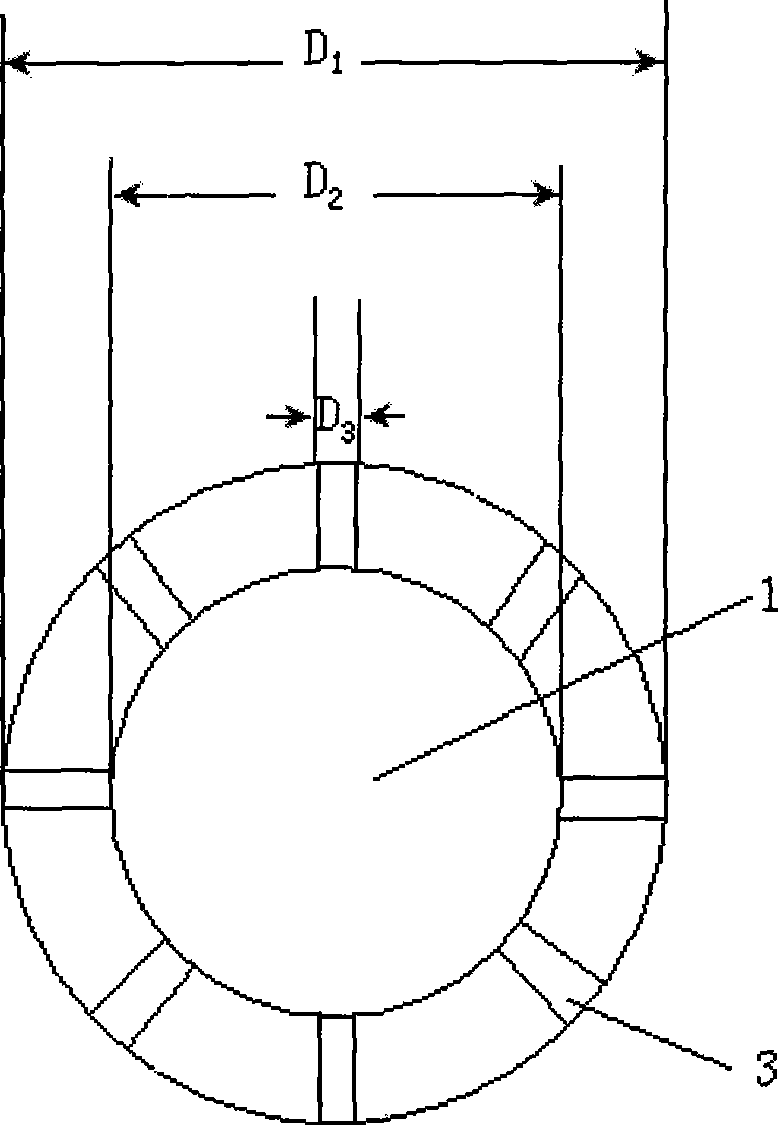

[0017] Such as figure 1 , 2 As shown, a special self-twisting hollow spindle for air-jet vortex spinning includes a fiber inlet 1 and a hollow spindle channel 2, and the fiber inlet 1 and the hollow spindle channel 2 are provided with 4 holes with the fiber inlet 1 and the hollow spindle channel 2. The center of the circle is a linear surface groove 3 distributed in a central circular array, and the diameter D of the fiber inlet 1 is 1 3mm, diameter D of hollow ingot channel 2 2 1.2mm, the width D of surface groove 3 3 0.1mm, the height H from the fiber inlet to the hollow ingot channel 1 8mm, hollow ingot channel height H 2 4mm, surface groove height H 3 is 0.1 mm, the chamfer angle θ of the fiber entrance 1 is 30°, and the inner surface of the surface groove 3 is streamlined.

Embodiment 2

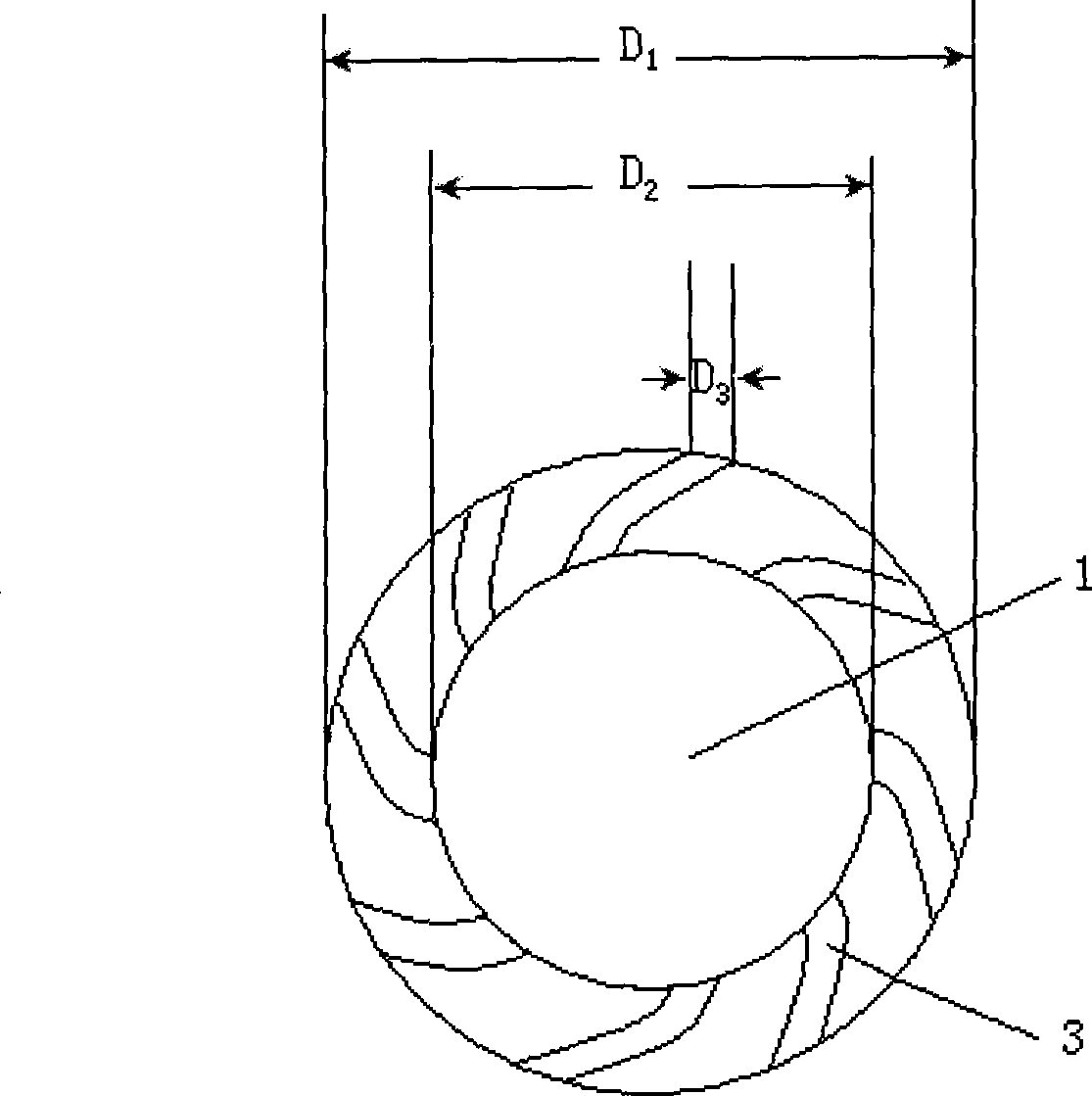

[0019] Such as figure 1 , 3 As shown, a self-twisting hollow spindle dedicated to air-jet vortex spinning includes a fiber inlet 1 and a hollow spindle passage 2, and eight fiber inlets 1 and hollow spindle passages 2 are provided on the fiber inlet 1 and hollow spindle passage 2. The center of the circle is the arc-shaped surface groove 3 distributed in the central circular array, and the diameter D of the fiber inlet 1 is 1 4mm, diameter D of hollow ingot channel 2 2 1.4mm, the width D of surface groove 3 3 0.4mm, the height H from the fiber entrance to the hollow ingot channel 1 9mm, hollow ingot channel height H 2 5mm, surface groove height H 3 is 0.4 mm, the chamfer angle θ of the fiber entrance 1 is 45°, and the inner surface of the surface groove 3 is streamlined.

Embodiment 3

[0021] Such as figure 1 , 3 As shown, a special self-twisting hollow spindle for air-jet vortex spinning includes a fiber inlet 1 and a hollow spindle channel 2, and the fiber inlet 1 and the hollow spindle channel 2 are provided with 6 holes with the fiber inlet 1 and the hollow spindle channel 2. The center of the circle is the arc-shaped surface groove 3 distributed in the central circular array, and the diameter D of the fiber inlet 1 is 1 5mm, diameter D of hollow ingot channel 2 2 1.6mm, the width D of surface groove 3 3 0.8mm, the height H from the fiber inlet to the hollow ingot channel 1 10mm, hollow ingot channel height H 2 6mm, surface groove height H 3 is 1 mm, the chamfer angle θ of the fiber entrance 1 is 60°, and the inner surface of the surface groove 3 is streamlined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com